With just 15 minutes of hands-on time, the small MIRO CANVAS offers real walk-away automation of intricate next-generation sequencing (NGS) library preparation and hybridization procedures.

The user-friendly and reasonably priced system uses new MIRO cartridges to reduce reagent use and generate high-quality findings using validated techniques for long-read sequencing, target enrichment, and on-demand sample processing.

- Fully automated

- Easy, walk-away automation for preparing NGS samples whenever needed

- Efficient

- Reduce expenses by up to 75% by using fewer reagents and requiring only 15 minutes of hands-on time

- Flexible

- Standardized procedures for preparing NGS samples for platforms that use both short- and long-read sequencing

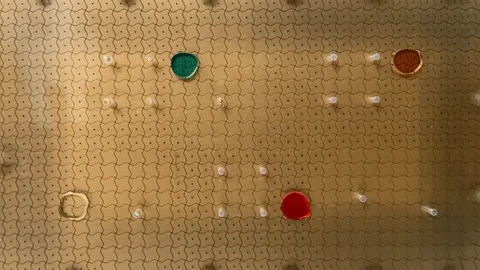

Droplets are controlled using digital microfluidics technology. Image Credit: INTEGRA Biosciences

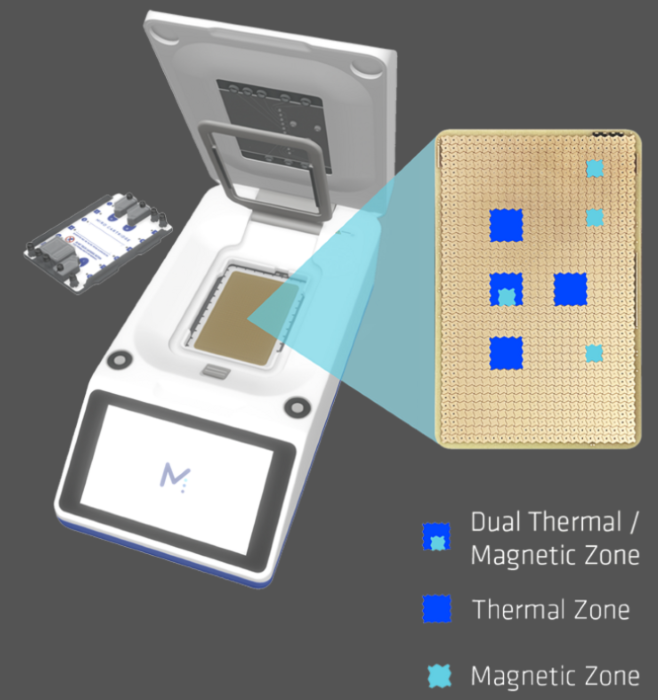

MIRO CANVAS uses digital microfluidics to execute sample preparation stages within a single MIRO cartridge. Samples and reagents are pipetted into the cartridge, and the microfluidics system executes the necessary sample and library preparation procedures without human intervention, producing samples for sequencing.

MIRO technology

MIRO technology employs electromechanical forces to propel droplets across an array of electrodes. The electrode board includes four thermal and four magnetic zones, allowing thermal cycling and magnetic bead operations to be done automatically. Droplets move within the cartridge, surrounded by air. The microfluidics technique also allows for volume reduction, which reduces operating expenses.

Image Credit: INTEGRA Biosciences

MIRO cartridge

The system uses MIRO cartridges, which provide a simple experimental setup and are compatible with all widely used reagents for sample preparation. It has no electronics and uses microfluidic channels layered on top of an open electrowetting plane. The electrodes on which the cartridge rests digitally regulate the droplet movement.

Image Credit: INTEGRA Biosciences

Full walk-away automation

The device minimizes hands-on time and offers full walkaway automation by integrating sample preparation procedures, including thermal cycling and magnetic bead operations. Throughout the run, the system detects reactions and ensures that all processes and reagents adhere to the same daily or site-specific protocol.

Image Credit: INTEGRA Biosciences

Simple run set-up

With the help of the MIRO CANVAS’s onboard touchscreen, the user can set up the run in just a few minutes. The system detects when a reagent has been loaded and notifies the user to proceed to the following phase.

Image Credit: INTEGRA Biosciences

Long DNA fragments

Long DNA fragments benefit from the mild environment created by the microfluidics technology utilized in MIRO CANVAS.

Image Credit: INTEGRA Biosciences

See it work

MIRO CANVAS – Fully automated NGS sample prep

Video Credit: INTEGRA Biosciences

Uses and applications

Overview

Key applications

- Long-read sequencing: The microfluidics platform uses fewer reagents and provides a gentle environment that is better suited for lengthy DNA segments

- Target enrichment hybridization: The system fully automates the most crucial phases in target enrichment, whether in single or multiplex sample formats

- On-demand sequencing: Samples can be processed as they arrive, eliminating the need for batching, which can be crucial in clinical applications

Applications

- Activating the MIRO CANVAS NGS preparation system with the Illumina DNA PCR-Free Library Prep kit

- Automate NGS library preparation

- Using the Twist Human Core Exome Kit on the MIRO CANVAS

- Automatic NGS library preparation and hybridization capture

- Automating PacBio® SMRTbell® whole genome sequencing library preparation on the MIRO CANVAS

- Easy sample preparation for long-read sequencing

- Automate the Oxford Nanopore Ligation Sequencing Kit on the MIRO CANVAS

- Easy long-read sequencing library preparation

Tech info

Here is a quick review of the product specifications.

Source: INTEGRA Biosciences

| |

|

| Dimensions |

20 x 41 x 18 cm (8 x 16 x 7”) |

| Weight |

6 kg (13 lb) |

| Power requirements |

100-240 VAC, 50/60 Hz |

| Operating conditions |

Temperature: 19-25 °C; Humidity: 20-80 %, non-condensing; Atmospheric pressure: 78-107 kPa |

| Space requirements |

Minimum 30 x 45 cm (W x D) on a stable surface |

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences

Image Credit: INTEGRA Biosciences