DSC 5+ from METTLER TOLEDO provides the next level of performance.

Thermal Analysis System DSC 5+

The new standard

- MultiStar™ sensor with 136 thermocouples

- Exceptional sensitivity for measuring weak impacts

- Power compensation

- Offers excellent resolution for differentiating close-lying effects

- Patented electrical heat flow adjustment

- Saves time while ensuring high measurement accuracy

Experience the future of lab automation in just 5 minutes

Explore the revolutionary new DSC 5+ robot

Differential Scanning Calorimeter DSC 5+ from METTLER TOLEDO

Video Credit: Mettler-Toledo International Inc.

More experiments, in a shorter time, with less resources

Measuring and evaluating samples takes time, and when numerous operators are involved, ensuring consistent interpretation and reproducible results becomes difficult.

High sample throughput with advanced hardware and software solutions

Up to 96 sample crucibles and seven reference crucibles are kept in the environmentally controlled crucible chamber for continuous monitoring.

Let the DSC 5+ robot take the effort out of the work

Up to seven reference crucibles can be placed in the reference tray, guaranteeing a level baseline for the measurements.

For safe handling of all crucible sizes, the sample crucibles can be placed into three different kinds of trays.

To avoid undesired interactions with the atmosphere before the samples are analyzed, the crucible chamber can be purged with an inert gas, such as nitrogen.

The samples are shielded until the measurement begins, avoiding undesirable processes like oxidation or alterations caused by the absorption or evaporation of moisture.

When handling crucible sizes ranging from 20 to 160 μL, the DSC 5+ universal robot grabber will instantly recognize various tray types.

Unique system of robot lid piercing and removal for sensitive samples

- Removable lid protects sensitive samples

- The lid’s precisely defined hole is created by the robot

- No contact with the sample

- The sample mass remained constant throughout the wait cycle

- Hermetical sealing of crucibles

Protect even the most sensitive samples

For delicate samples, the crucible can be completely sealed to prevent sample mass changes before the measurement begins.

Just before the measurement begins, the DSC 5+ robot’s built-in needle pierces the specific crucible lid, leaving a precisely defined hole without coming into contact with the sample.

Sensitive samples can also be protected by a specific removable cover.

The robot lifts the lid immediately before measurement begins.

After the measurement, the robot replaces the cover on the crucible and returns it to the tray.

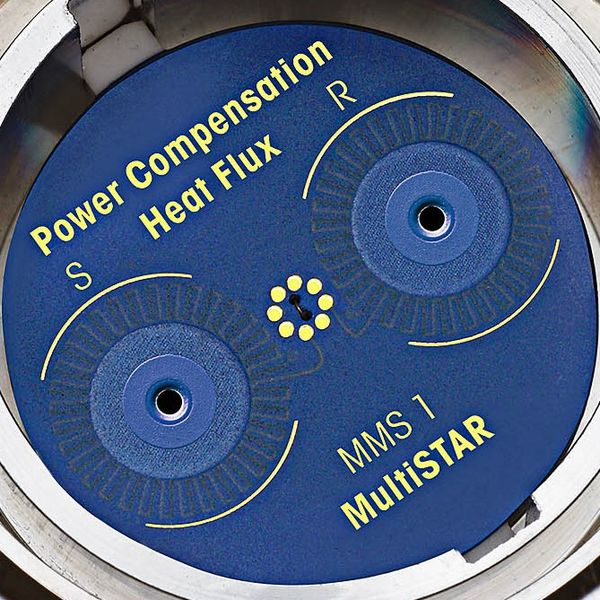

Unique power compensation mode

Outstanding resolution for the separation of close-lying effects

The addition of heating components in the sensor enables a power compensation measurement mode.

A single furnace DSC can be measured with power compensation for the first time.

This gives a single sensor a high signal-to-noise ratio for remarkable sensitivity and an incredibly rapid signal time constant for great resolution.

How does power compensation work?

The goal of Power Compensation mode is to minimize the temperature difference between the reference and sample sides.

Two local heaters—one beneath the sample crucible and one beneath the reference crucible—are used on the MMS 1 DSC sensor to accomplish this.

As long as the sample has no thermal effect, the temperature difference (ΔT) between it and the reference is zero. A thermal effect causes the sample temperature to differ from the reference temperature.

An exothermic event, like crystallization, for instance, causes the sample to release energy and warm up more than the reference. Once the reference side heater is turned on, the reference temperature will rise until it equals the sample temperature (ΔT = 0).

The sample gets cooler than the reference when an endothermic process, like melting, occurs. Following activation of the sample heater, the sample temperature will rise until it reaches the reference temperature.

What is the benefit of power compensation mode in the new DSC 5+?

The power injected by sensor heaters to bring ΔT to zero is properly monitored.

As a result, the heat flow signal has exceptional resolution and close-lying effect separation.

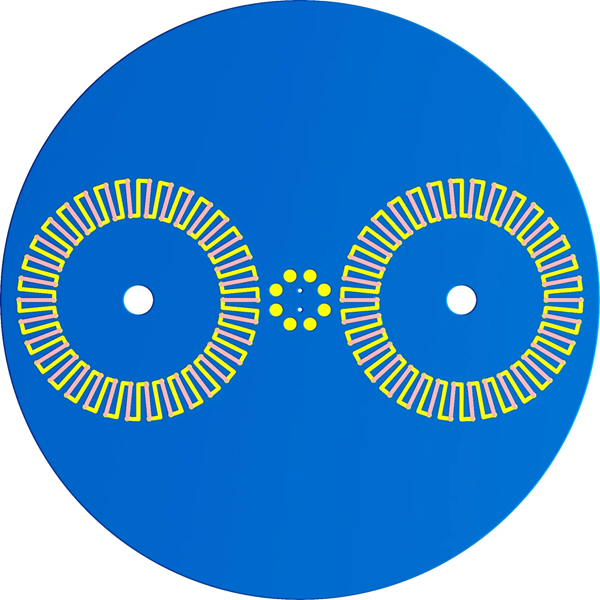

Revolutionary MMS 1 sensor with 136 thermocouples and 2 integrated heaters for power compensation

Exceptional sensitivity for the measurement of weak effects

Image Credit: Mettler-Toledo International Inc

Power compensation or Heat Flux Mode?

Depending on the requirements of the analysis, users can switch between Power Compensation and Heat Flux mode in the DSC 5+, thanks to two integrated heaters in the innovative MMS 1 sensor.

Excellent resolution for the separation of close-lying thermal effects is provided by the highly accurate measurement of the power introduced by the sensor heaters in Power Compensation mode.

High degrees of sensitivity are offered by both the Power Compensation and Heat Flux modes for detecting subtle changes in the sample.

Depending on the requirements of the experiment, users can select either the Power Compensation mode or the Heat Flux option.

Layering system of MMS 1 sensor

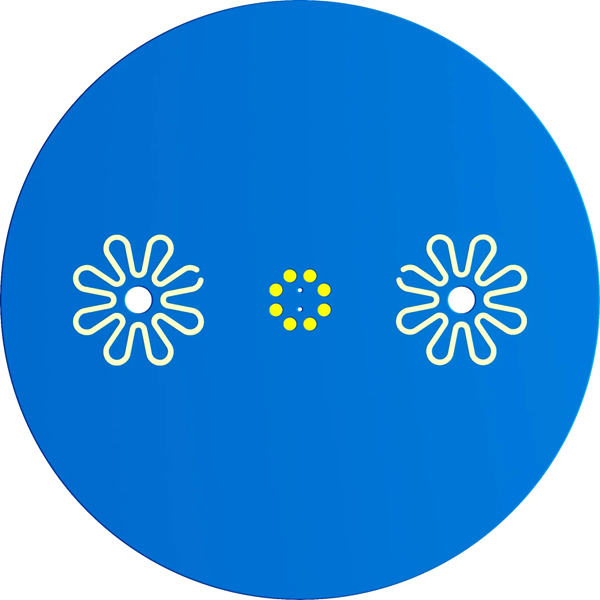

Layers 1 and 2: 136 Thermocouples

Image Credit: Mettler-Toledo International Inc

The thermocouples’ star-shaped configuration produces flat baselines and removes drift.

When combined with a new improved cell design, it achieves world-class baseline quality and Cp precision.

Layers 1 and 2 determine the temperature differential between the sample and the reference.

Each layer has 68 thermocouples, which amplifies the measurement signal and produces extremely low noise for a more sensitive DSC.

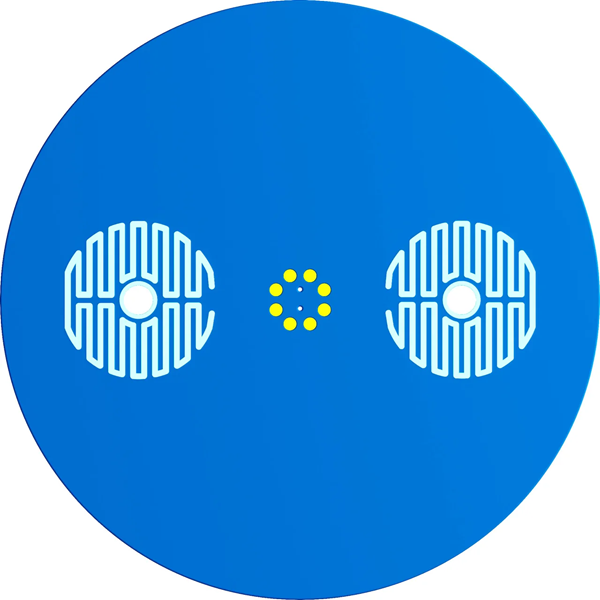

Layer 3: Two heaters for power compensation

Image Credit: Mettler-Toledo International Inc

At the sample and reference locations are two integrated heaters (250 µW each), which turn on during measurements in power compensation mode.

Maintaining the temperature difference between the sample and reference near zero is the goal of the power compensation mode.

Exothermic effect: The temperature on the sample side increases. The heater on the reference side will then operate, raising the reference temperature until it reaches the sample temperature.

Endothermic effect: The sample grows cooler than the reference. The sample heater will then operate, raising the sample temperature until it reaches the reference temperature.

Layer 4: Absolute sample and reference temperature sensors

Image Credit: Mettler-Toledo International Inc

The absolute temperature of the reference and sample crucibles is carefully measured by two temperature sensors.

The temperature range that the MMS 1 sensor can measure is -150 to +700 °C.

For the first time in DSC history, electrical heat flow adjustment is available for the entire temperature range

A significant advancement in DSC technology is represented by the DSC 5+’s novel MMS 1 sensor.

It has a sensor that can precisely self-adjust for heat flow and two built-in heaters that allow for the patented electrical heat flow adjustment.

The heaters deliver a 50 K heat pulse during the adjustment process, and the temperature sensors precisely record the reaction.

The heat flow is measured throughout a temperature range that reference materials cannot reach, with no sample preparation required and no operator bias. The end result is a DSC that is always properly calibrated across the whole temperature range.

This innovative function, automatic instrument adjustment, allows users to save critical time while increasing productivity.

Measure at any temperature, in any aggressive atmosphere

The ceramic MMS 1 sensor is extremely durable and chemically resistant.

Measurements can be taken at high temperatures in harsh environments without risk of corrosion.

Heat Flux mode

Guaranteed flat baseline and exceptional sensitivity for the measurement of weak effects

How does Heat Flux mode work?

In a DSC experiment, both the sample and reference crucibles are enclosed in a heated chamber or furnace.

The sensor, which is at the heart of a DSC module, monitors heat transfer from the furnace to the sample and reference.

The DSC 5+ sensor features a star-shaped arrangement of thermocouples, ensuring a flat baseline and great sensitivity for sensing weak impacts.

If a thermal effect occurs in the sample, the temperature will differ from the reference temperature, which corresponds to the programmed temperature.

In Heat Flux mode, ∆T refers to the temperature difference between the sample and reference sides of the sensor.

How is heat flow calculated in Heat Flux mode?

The measurement curve in the diagram above depicts a typical exothermic crystallization peak in red and an endothermic melting peak in blue, with heat flow plotted against temperature.

A thermal effect in the sample, such as crystallization or melting, causes the sample temperature to differ from the reference temperature.

In Heat Flux mode, heat flow is estimated using the measured ∆T value, which is the difference between the sample and reference.

Guaranteed repeatable results regardless of the operators and their experience level

- Hands-free access to the furnace

- Automatic crucible disposal if needed

- Automatic exchange of the reference crucible

- Automatic return of the sample crucible to the tray

Ensure a flat baseline for the measurements

When the sample crucible type changes, the robot automatically replaces the reference crucible, ensuring a consistent baseline for the measurements.

The robot subsequently deposits the sample on the sensor, and the measurement begins. Following the measurement, the robot returns the sample crucible to its tray.

Sensitive samples are protected with a lid, which is removed by the robot right before the measurement begins.

After the measurement, the robot replaces the lid on the crucible and returns it to the tray.

Prevent contamination of fresh samples with automatic crucible disposal

The DSC 5+ robot discards the crucible in a designated crucible bin following the measurement.

This keeps the crucible chamber’s fresh samples from becoming contaminated. Savor a more fruitful DSC that increases lab productivity.

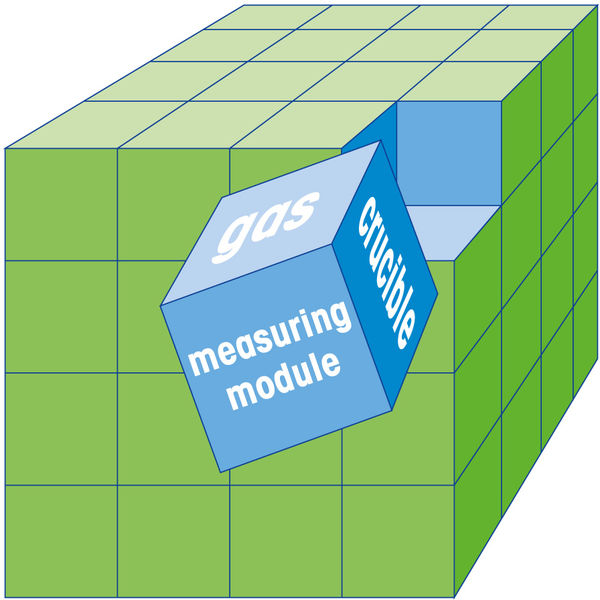

Unrivalled modular concept

Protect the investment with a fully modular and upgradable solution, customized for the current and future needs

The requirements for each laboratory's measurement needs are unique.

The optimum user experience can be achieved by customizing the products.

Every option is selected at the time of purchase, but the system is easily upgradeable if the user needs to change over time, protecting the investment.

DSC 5+ modules

Image Credit: Mettler-Toledo International Inc

1. Base DSC 5+, simple and elegant

When manually adding or removing crucibles, users can easily manage the furnace lid and operate the DSC 5+ module from a PC running the STARe software. A stylish and simple way to organize the workspace.

2. Interactive touch screen

If the DSC is not adjacent to the PC, include an intuitive touch screen to conveniently control the module and check the status of the experiments. Launch preconfigured methods fast and effortlessly with OneClick™. Simply choose the method, provide the sample name and mass, and users are ready to measure.

3. Hands-free access to furnace

The automatic furnace lid is simple to use and eliminates the possibility of contamination from manual handling and setting the lid on an unclean surface. The lid is always correctly placed on the furnace, regardless of the operator, ensuring reproducible measurement conditions and user safety.

4. Complete robot automation

The 3-axis sample robot allows the user to run more tests in less time and with fewer resources. With automatic reference crucible handling, crucible lid piercing, and crucible disposal functions, the sample robot can totally automate the measurements.

5. Sustainable cooling

For optimum cooling flexibility, use a CombiCooler to connect liquid nitrogen and an intracooler. To save energy, the instrument will automatically pick the appropriate cooling device for the procedure, utilizing liquid nitrogen only when necessary by the measurement conditions.

AI Wizard™ - Automate the entire experiment process and resolve the challenging questions

- How can unknown samples be identified?

- What type of effect is being observed?

- Where does the effect begin and end?

- What is the ideal choice of the baseline?

- Are there overlapping effects or artifacts?

The innovative AI-powered identification and evaluation answers all those questions for users

The TA professionals have over 350 years of collective experience!

This outstanding level of experience enabled users to develop the AI Wizard neural networks, which were trained on thousands of real-world evaluations.

AI Analysis autonomously examines and identifies all thermal effects in the experiment.

Simply engage the AI Wizard in the procedure to instantly, and autonomously evaluate and identify DSC thermal occurrences.

AI Wizard can be utilized as an expert for automated measurement analysis or as an independent second opinion reviewer.

Utilize its unique qualities for the laboratory:

Expert opinion

Compare user’s own evaluation with the AI Wizard

AI Wizard can serve as a second expert viewpoint. After the experiment, simply click AI Wizard in the assessment window to receive an instant autonomous evaluation to compare to the user’s own analysis.

Alternatively, employ the automated process by selecting AI Wizard in the Method or Routine window of the STARe software. This automates the entire measurement, review, and identification process, freeing up crucial time for the analysts.

Multiple neural networks for user’s choice

Choose a dedicated neural network trained on selected data for optimal evaluation

Thermal effects can vary greatly among material classes. Thus, limiting the training data set enhances neural network quality, resulting in even better results.

Thermal effects can vary greatly among material classes. Thus, limiting the training data set enhances neural network quality, resulting in even better results.

Upgradable neural networks

Meet future needs with continuous additions of AI expert data

The neural network database is separate from the STARe software, which allows it to be updated separately.

This enables users to continue adding expert data, ensuring that AI Wizard continues to fulfill their needs.

Automation with AI enabled methods

Runs experiments and analyzes results instantaneously

The STARe software and AI Wizard allow users to automate the entire experimentation process.

Simply engage the AI Wizard in the procedure to instantly, autonomously evaluate and identify DSC thermal occurrences.

Place trust in METTLER TOLEDO’s thermal analysis experience

AIWizard™ for Intelligent Evaluation

Video Credit: Mettler-Toledo International Inc.

Equip the DSC 5+ with the most comprehensive thermal analysis software STARe and benefit from:

- Modular concept

- Extremely flexible

- Dependable automation

- Infinite evaluation possibilities

AI Wizard is one of the many beneficial features included in the STARe software.

Its distinctive qualities make it the best software for facilitating compliance with internal and external laws.

All thermal analysis systems may be controlled using a single sophisticated STARe software platform.

Use the DSC 5+ module with a PC running the STARe software to effortlessly manage the furnace lid when manually putting or removing crucibles.

Explore unrivaled flexibility with the Modular STARe software

The base software offers a wide number of regular evaluations that can be applied to curves obtained using various measurement techniques.

Mathematical evaluation characteristics include:

- First derivative

- Cut to frame – cutting segments

- Take apart

- Envelope curves

- Subtract lines

Other evaluation functionalities include:

- Min/Max: determination of the minimum and maximum values within a selected region

- Normalize to sample size: conversion to W/g or % presentation

- Display curve against time, reference, or sample temperature

- DSC purity

- Automatic evaluations and validations

- ADSC–FFT, steady state ADSC, and ADSC to separate overlapping effects

- Onset and endset, with and without threshold values

- Peak integration

- Step, with horizontal or tangential baselines

- Table: different options for presenting curves in tabular form

Features

FlexMode™ technology

Image Credit: Mettler-Toledo International Inc

For maximum DSC performance, select either power compensation or heat flux mode.

Time-saving FlexCal™ adjustment

Image Credit: Mettler-Toledo International Inc

Ensures accurate results in all measurement conditions.

Unrivaled modular concept

Image Credit: Mettler-Toledo International Inc

Tailored solutions for present and future requirements.

Wide temperature range

Image Credit: Mettler-Toledo International Inc

From –150 to 700 °C in one measurement.

Robot with gas-purged sample chamber

Image Credit: Mettler-Toledo International Inc

The optional sample robot reliably works around the clock and shields samples from the environment.

CombiCooler

Image Credit: Mettler-Toledo International Inc

Using a combination of LN2 cooling and intracooler allows users to access the full temperature range while using less liquid nitrogen.

Specifications

Specifications - Thermal Analysis System DSC 5+. Source: Mettler-Toledo International Inc

| |

|

| Temperature Range |

-150 °C – 700 °C |

| Temperature accuracy (±) |

+/-0.2 K |

| Signal Time Constant |

0.7 s |

| Indium peak (height to width) |

25 |

| Cooling rate |

0.001 to 50 K/min |

| TAWN resolution |

4 |

| TAWN sensitivity |

66 |

| Technique |

Differential Scanning Calorimetry (DSC) |

| Sensor Output |

Heat Flow |

| Data Sampling |

Max. 50 data pts/sec |

| Applications |

Crystallization

Glass Transition

Heat Capacity (cp)

Kinetics

Oxidation Induction Time (OIT)

Temperature Modulated DSC |

| Sensor Types |

MMS 1 |

| Temperature precision (+/-) |

0.02 K |

| Heating Rate |

0.001 to 200 K/min |