Not much… at least not yet. While titanium is used widely for more conventional macro-scale medical devices (e.g. hip implants, dental implants, and cardiac pacemakers), its use for micro- and nano-scale devices has been limited thus far.

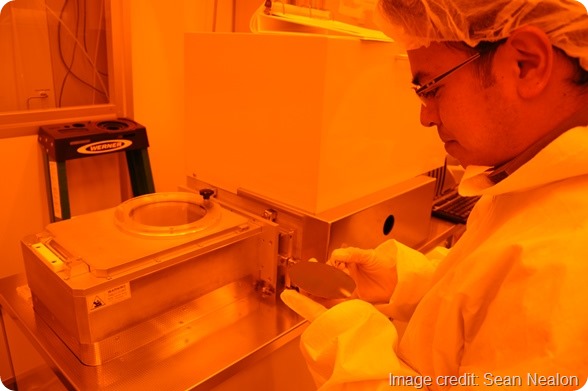

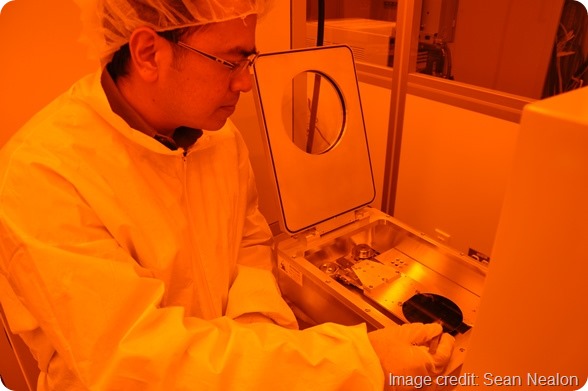

This limitation is due, in large part, to the lack of fabrication technologies that can provide access to these reduced length scales. Our recently-developed titanium deep reactive ion etching (Ti DRIE) technology now addresses this limitation.

As such, we believe that it will provide new opportunity for realization of radically miniaturized medical devices, and do so using a material with well-proven biocompatibility in chronic implantation applications.

Examples of devices currently under development in our lab include microneedles for minimally-invasive drug delivery, pro-healing vascular stents, and robust neural prosthetic interfaces.

You recently received a five-year, $400,000 Faculty Early Career Development (CAREER) award from the National Science Foundation to try to strengthen miniaturized titanium-based medical devices. Why are the current devices not strong enough?

While titanium-based micro- and nano-scale medical devices are not yet available, nearly all macro-scale metallic parts in use today rely on some form of strengthening (e.g. alloying) to enhance their performance and reliability.

Interestingly, however, there has been minimal consideration of strengthening for micro- and nano-scale devices thus far. This is due, in large part, to limitations imposed by current micromachining techniques.

For example, our Ti DRIE technique only works with pure Ti, due to the highly chemical nature of the material removal mechanism upon which it is based. This, therefore, precludes opportunity for using other high strength biomedical alloys (e.g. stainless steel), or even high strength Ti alloys (e.g. Ti 6-4), since all contain additional metallic elements that adversely affect the micromachining process.

What benefits would there be of strengthened miniaturized medical devices made from titanium?

As at the macro-scale, the performance and reliability of micro- and nano-scale devices could be enhanced significantly if we can increase their strength.

The titanium-based microneedle devices we’re currently developing represent one of many examples in this regard. Microneedles are micro-scale penetrating structures that are, in the simplest sense, highly miniaturized versions of conventional hypodermic needles.

The diminutive size of microneedles provides opportunity for significantly reducing damage during tissue penetration, which may ultimately lead to reduced healing time and increased device performance.

In collaboration with Malik Kahook, a Professor in the Department of Ophthalmology at the University of Colorado, we’ve been exploring potential for developing microneedles for delivering drugs to the eye.

Since these devices are intended for penetration of relatively robust but also highly sensitive tissues, such as cornea and sclera, strength is crucial.

Moreover, increased strength will allow us to make smaller devices, which will reduce tissue trauma and insertion force, both of which are important performance metrics.

How do you plan to develop techniques to strengthen miniaturized titanium-based medical devices?

While numerous methods exist for strengthening at the macro-scale, few are translatable to the micro- and nano-scale. However, one method that does show promise in this regard is gas nitriding, which is used widely for increasing the wear resistance of conventional macro-scale metal parts (e.g. case hardened engine camshafts).

We believe this technique holds significant potential for our miniaturized medical devices, since it can be applied after they have been fabricated, thus circumventing the aforementioned process compatibility limitations.

However, it’s important to emphasize that translation of this technique to our devices won’t be as simple dropping them into a conventional nitriding furnace. There are a number of potential tradeoffs unique to the micro- and nano-scale that need to be better understood to assess feasibility.

How has your work been influenced by automotive manufacturing?

Our work isn’t influenced by automotive manufacturing per se, but rather by advanced manufacturing in general. This influence arises from the unique opportunity that now exists for tapping decades of advances in conventional metal processing to enhance the performance and reliability of our devices.

The translation of gas nitriding to the micro- and nano-scale represents one example of this. However, we also foresee opportunity for translation in the opposite direction as well.

Specifically, we envision potential for use of Ti DRIE to enhance the performance and/or functionality of conventional macro-scale devices through the fabrication of micro- or nano-scale structures directly within larger macro-scale titanium parts.

For example, it’s conceivable that our Ti DRIE process could allow the integration of micro-scale pressure sensors directly within hip implants. This could then provide opportunity for long-term monitoring of load transfer from the surrounding bone, thus allowing detection of implant loosening well before irreversible damage has occurred.

Do you think medical device manufacturing should take inspiration from any other applications?

Certainly, there’s still much that can be learned from other applications. For example, over the past few decades, there has been increasing interest in looking to Nature for new solutions to challenging problems in many fields.

The pro-healing vascular stents we’re currently developing represent one of many examples in this regard. Stents are millimeter-scale scaffolds that are used to prop open arteries clogged by plaque buildup.

While stents have been in widespread use for more than a decade, a small percentage of patients receiving such devices still suffer from serious complications that arise from incomplete healing of the vessel around the stent.

In collaboration with Victor Rodgers, a Professor in the Department of Bioengineering here at UCR, we’ve been exploring potential for reducing such complications through the creation of precisely-defined, nano-scale, grating-like structures on the surface of titanium-based stents that may accelerate the healing process.

Although the exact mechanisms are still not well understood, it’s hypothesized that such structures facilitate more favorable cellular interactions with the stent surface, since they begin to mimic the topography of the native extracellular matrix that cells interact with in the body.

How long do you think it will take for you to develop techniques to strengthen miniaturized titanium-based medical devices?

Provided all goes according to plan, we should have proof-of-concept within the next few years. Application to our ongoing device development efforts should then follow soon after.

How do you think the future of miniaturized titanium-based medical devices will develop?

By providing opportunity for not only machining titanium-based structures at unprecedentedly small length-scales, but also tightly integrating multiple functionalities within such structures (e.g. electrical, fluidic, thermal, etc.), we believe that Ti DRIE will serve as a fundamentally enabling platform technology for miniaturized medical devices.

Our current efforts in vascular intervention, minimally-invasive drug delivery, and neuroprosthetics represent the tip of the iceberg in this respect. As such, we look forward to working with clinicians, researchers, and medical device manufacturers to help identify and address compelling underserved or unmet needs in these and other areas.

Where can readers find more information?

Further information can be found on Prof. Rao’s Biomedical Microdevices Laboratory website: https://www.engr.ucr.edu/

About Dr Masaru Rao

Prof. Rao received his B.S. in Material Science & Engineering from the University of Florida with specialization in metallurgy. He received his Ph.D. in Materials Engineering from the University of California, Santa Barbara (UCSB), under the supervision of Prof. Fred Lange in the area of structural ceramics.

Prof. Rao received his B.S. in Material Science & Engineering from the University of Florida with specialization in metallurgy. He received his Ph.D. in Materials Engineering from the University of California, Santa Barbara (UCSB), under the supervision of Prof. Fred Lange in the area of structural ceramics.

Following graduation, he accepted a post-doctoral researcher position in Prof. Noel MacDonald’s group in the Mechanical Engineering Department at UCSB, where he was an integral member of the team that developed plasma-based micromachining techniques that allow, for the first time, deep reactive ion etching of bulk titanium.

He joined Purdue University as an Assistant Professor in the School of Mechanical Engineering and School of Materials Engineering (by courtesy) in January 2007.

He moved to the Department of Mechanical Engineering at the University of California, Riverside (UCR) in January 2009, and is a Core Faculty Member in the Materials Science & Engineering Program and Participating Faculty member in the Department of Bioengineering.

Prof. Rao’s research interests lie in the development of fundamentally enabling MicroElectroMechanical Systems (MEMS) based process technologies, devices, and instruments that address critical needs in public health, facilitate scientific inquiry, and advance understanding in areas of medical relevance.

Current efforts primarily focus on development of biomedical microdevices for applications including cardiovascular intervention, minimally-invasive drug delivery, neuroprostheses, and ultrahigh throughput cellular manipulation.

He has authored/co-authored over 30 journal articles and conference proceedings, has 2 awarded and 3 pending patents, and has presented invited lectures in fields ranging from ceramic composites to MEMS.

Prof. Rao is a recipient of the NSF CAREER Award (2013) and is a member of the ASME MEMS Division, Biomedical Engineering Society, Materials Research Society, IEEE Engineering in Medicine & Biology Society, and the IEEE Electron Devices Society.

Prof. Rao’s research is funded by a variety of federal agencies (NIH, NSF, & DoD), as well as industrial and internal sponsors.