Sep 2 2015

Morgan Advanced Materials has announced plans to launch its own range of standard brazed filament supports, complementing its existing portfolio of high-specification products.

The world leader in advanced materials will draw upon more than 30 years of manufacturing expertise to respond to the growing demand for standard-sized filament supports within the analytical market, enabling a greater degree of flexibility and responsiveness to evolving customer requirements. The availability of standard components means significantly shorter lead times, giving Morgan’s customers the added option of an ‘off the shelf’ solution.

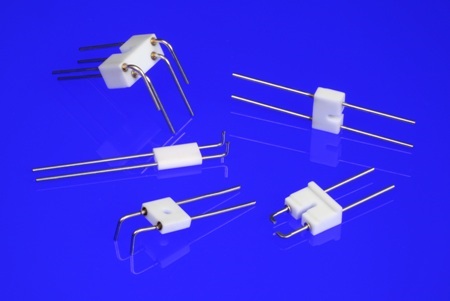

Used in x-ray and analytical equipment, predominantly in the medical and scientific research sectors, Morgan’s brazed ceramic filament supports are available in standard and custom shapes, in small and large volumes. The standard range is produced using Morgan’s proven high purity alumina grade Sintox FF. Compared to alternative materials, ceramic boasts optimal thermal and electrical insulation, a low coefficient of thermal expansion and superior dimensional accuracy.

Customers can choose between two and four-pin options, with the pins brazed in position with ceramics for filament welding. Custom designs are also available to suit specific requirements, incorporating variations in pin size, form and material. A variety of braze materials can be used, including gold nickel, gold copper and silver copper eutectic.

Suhan Wang, Efficiency and Process Engineer at Morgan, commented:

We are always keen to investigate innovative ways to adapt to the changing needs of the market and by offering standard ranges, we will be able to respond more quickly to customer requirements while still offering customised designs when needed. A range of material grades are available for custom products, depending on the requirement.

Source: http://www.morgantechnicalceramics.com/