If you are a care home in the UK, you will have almost certainly thrown away a moving and handling sling in the last few months because the specification label is faded. Why? Read on…

LOLER Inspections

In a car home, every 6 months, a LOLER inspection has to be carried out on all patient lifting equipment (e.g. hoists and slings). When a service engineer inspects the safety of slings, they assess obvious safety hazards such as dangerous wear, material break-down and loose stitching. They also look at the state of the specification label on the sling.

Find out more about LOLER inspections

There are obvious safety reasons why a sling may be condemned after a LOLER inspection. A sling’s condition inevitably deteriorates after heavy use and frequent washing, and it is understandable that they have to be thrown away. However, condemning a sling because of a faded specification label seems rather absurd.

Faded Sling Specification Labels

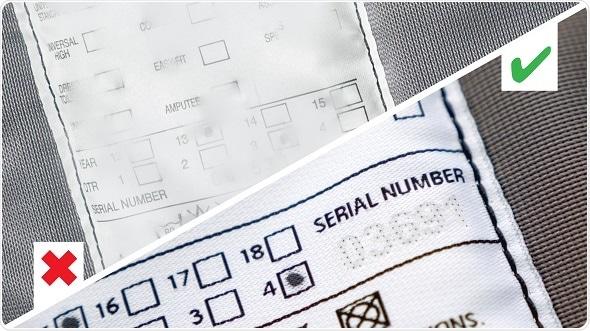

For a handling sling to pass its LOLER test, the safe working load on the specification label must be clearly visible. If it is not, the engineer will need to use the serial number on the sling to contact the manufacturer and find out the safe working load. However, if the serial number is not visible either, the sling is condemned and has to be thrown away.

This is a surprisingly widespread reason why so many slings are condemned, with each wash of a sling causing the ink on the label to fade and become less visible. It isn't long before both the safe working load and the serial number are unreadable, resulting in an otherwise perfectly safe sling being condemned and thrown away, just because the specification label is faded.

The Mouva® Solution!

Not only is throwing away a sling because of a faded label wasteful, but also the constant renewal of slings is very costly for a care home.

Alpine HC manufacture the Mouva® range of moving and handling slings, and they set about developing a solution. After listening to the frustration of nurses and care home operators, Alpine HC have designed, constructed and recently-launched a new specification label for their British quality-made slings.

Sling resource - Mouva® Sling Measurement Guide

Rather than ink-printed, all specification labels on Mouva® slings are now fully embroidered. Intricate stitching replaces ink to ensure the details on the label will never wash out or fade.

On top of this, the serial number of each Mouva® sling is laser-etched onto the label. This provides a virtually indestructible fall-back for the LOLER inspectors should the safe-working load ever become unreadable.

Browse the full range of Mouva® slings