News-Medical speaks to David Dambman from Biosero about the emerging importance of automation in scientific research and how a centralized scheduling software is an essential first step for any laboratory looking to automate their workflow.

Why has automation become so critical to advancing scientific research?

There are many reasons why automation is useful in scientific research. First and foremost, automation is about being able to walk away from your experiments and spend time analyzing your results, rather than carrying out mundane tasks such as transferring liquids from one plate to another.

kung_tom | Shutterstock

kung_tom | Shutterstock

People often think that automation is about making things faster, but this isn’t always the case. Human beings are extremely agile and can move items very quickly, but they're not as consistent as automation is. This creates problems with reproducibility. In research, scientists need to be able to repeat experiments that have been published and obtain the same results. Automation is critical here, as it eliminates the variability introduced by humans.

One way that automation is advancing scientific research is by sparking innovation. When you are given new techniques and technologies, it sparks ideas. This could be a new way of executing your workflow or new ideas for assays or processes.

What are the greatest areas of development right now for laboratory automation?

The industry is quite broad, so it’s hard to say which areas are growing the most. However, I think that one of the key areas of innovation is collaborative automation, or cobots. These are robots that work alongside humans, automating some processes, and leaving others manual.

You often see this in the progression of the development of a workflow, when a company is starting to bring automation into the early phases of assay development. These companies will start with a workflow that is fully manual, but guided by software, and then add components as they become available.

This is where our scheduling software, Green Button Go, fits in. Automation is not just about controlling instruments, it’s about controlling your workflow. So, you start off with human beings processing the samples at every stage, then slowly bring in automated technologies where you need the consistency and the throughput. Slowly, this evolves into a highly efficient process where results are reproducible.

As technology improves, the steps that are currently manual can then be automated. Traditional industrial robots have to be enclosed behind safety barriers to prevent humans from being harmed in the process. As cobotics grows, the need for such high level safety measures will be reduced, and automation will evolve into an everyday part of research, even for low-throughput laboratories.

How is Biosero contributing to the automation of laboratory operations?

Our primary focus is software, but we also offer integration services. We work with customers to design and implement automated solutions that work for them.

Our key product is the Green Button Go software, which is a scheduling software for integrated laboratories. The unique thing about this software is that it’s completely hardware agnostic. This means you can use the instruments of your choice, and you aren’t tied to any specific vendor. As new instruments become available from different vendors, you can download drivers and updates to our software from the cloud.

This is important as the rate at which technology is evolving is exponential. People used to invest in an automation platform and expect to run it for five to ten years. Now, with the acceleration that we’re seeing, it may only be 18 months before the system is outdated. This is particularly true for NGS platforms.

Instead, many companies are now choosing to commit to a software platform that’s hardware agnostic. This allows you to evolve as technology advances.

I think that’s one of the biggest things that sets Biosero apart from our competitors; a platform that isn't dependent on any particular brand of hardware, or any particular technology. It's a platform that it can evolve with their science.

Bork | Shutterstock

Bork | Shutterstock

Please can you describe the Green Button Go software and its applications in research?

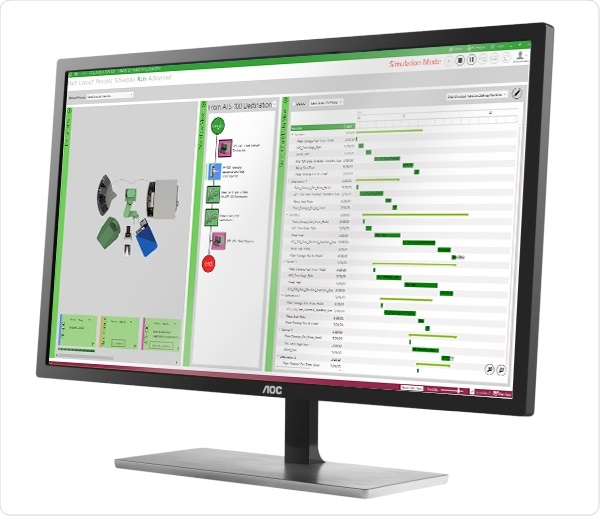

As previously mentioned, Green Button Go is a scheduling software that can be integrated into any workflow.

Our device drivers can be found in the cloud. This means that when a new equipment comes to market, such as a new imaging platform, for example, we simply write a new interface and add it to our cloud library. Users can then go to this library, download the code and add it to their workcell.

We designed our software to include a really simple drag and drop interface that allows scientists to easily design their workflow. It’s as simple as dragging and dropping the hardware together, then dragging out the process steps and pressing the green play button to execute the entire workflow.

Once the system is running, you have full visibility of every single plate or tube in the process. You also know exactly where all of your labware is and the utilization of every single instrument. Further to this, we have a fantastic behind the scenes data infrastructure that tracks, streams and captures all of the data that’s being generated by the system. It’s a great platform that you can build upon and start to incorporate AI machine learning initiatives into.

As we schedule and control the whole process, we not only have the raw data from the instruments, but also the workflows, user activity and data on the context around this. All of this information allows us to really transform raw data into real information and knowledge.

Powered by Green Button Go - OMRON's Mobile Robot

What are the major benefits of the Green Button Go software?

The major benefit is the hardware agnostic aspect. It doesn't matter what instruments you're using, we can integrate them, whether it's Tecan, Hamilton, Beckman or any other liquid handler, it will work. This allows our customers to evolve their platform as their science evolves.

There are also two other very useful aspects of the technology. One is ease of use; if you’re not an automation engineer and all you want to do is define your workflow and execute it, Green Button Go is the answer. We can lock the features down and make the software easy to use.

On the flip side, if you are an engineer, Green Button Go gives you in-depth control of every single aspect of the system. This allows you to write scripts that can connect to databases, and dive deep into the data and control your processes in a non-traditional way, which is especially useful in research.

Green Button Go uses powerful scripting engines that utilize languages like Python, which are not traditionally used in automation software, but have become really key languages for technologists and advancing machine learning.

To summarize, we cater to the ease of use that many of the laboratory technicians and managers need, but also to the really advanced capabilities that are required by people who are really pushing science forward.

What advice would you give to scientists looking to automate their laboratory processes? Where should they start?

For people who are new to automation, there’s often a tendency to want to automate the entire lab straight away! This is a great mindset, but I think it’s important to carefully look at your workflow first. As an end user and a scientist, you need to pick the areas that need to be automated for consistency or throughput first, then build upon them. It is for this reason that you need a platform that can evolve with you.

If you try to do too much, too quickly, it can have disastrous and very expensive consequences. With automation, you don’t always know the pitfalls that will come. The best thing you can do is spend time planning a good rollout process for automated platforms in your laboratory, and make sure you have a management system in place.

You should try to pick a partner that can provide advice on all aspects of automation, and isn’t focused on selling you a particular hardware.

How do you expect scientific research to evolve over the next 50 years as more and more processes become automated?

I think we will reach a stage where automation is everywhere, but I don’t think it will look the way that many people think it will. It’s always going to be faster to do one step manually than to automate it, so developing robots that can safely work alongside humans is the immediate focus.

Another major driving force in automation is artificial intelligence. Unfortunately, AI can’t be implemented until everything is properly tracked, and all the data is easily accessible. AI requires a process from which to learn from, so recording all of this data will be essential for future applications.

The immediate future will involve manually designing an experiment and pipetting for some stages, but the main difference is that the pipette, for example, will be communicating with a piece of software. The software will record the volumes that were transferred, the times that the solutions were transferred and so on.

So, it's not just automating instruments and sample handling, it's automating the data that's the most important thing. The biggest breakthroughs in science are going to come from the intelligence that can analyze that data and see patterns that human beings aren't capable of seeing. This doesn’t mean installing huge rooms full of robots, it simply means that human beings need to be connected, and their workflow properly tracked and guided.

That's a step that Green Button Go can really help scientists with; whether it's guiding robots to move samples around, guiding humans, or simply tracking all of the data.

What’s next for Biosero?

Our biggest area of development right now is in the data area. We’re focused on automating day to day tasks such as automatic reordering, managing workflows that you're developing on the bench, and helping to track and execute those in a consistent and reliable way.

Second to this, we’re focused on large order management capabilities and insight into your platform. The more automation that you have in your organization, the more you want to be able to drive things like purchasing decisions, based on instrument and workcell utilization. The Green Button Go dashboard platform gives you that kind of insight, and we're building up a lot of new analytics tools for that to allow decisions at every level.

A technician may want to look at the dashboard to ask, "Which instruments or workcells are available for my work?", whereas a lab manager wants to look at it and say, "What was the uptime of the systems? Where were the most errors? How can I improve my workcells by replacing hardware that may be problematic, with new hardware that's more reliable?"

Then you have your executive-level view, where you want to look at and ask "After investing $200 million in automation, which platforms are being used the most and which ones should be repurposed?” If one system is being used 84% of the time, and another is being used only 14% of the time, the executive will want to solve that imbalance.

Where can readers find more information?

About David Dambman

As Director of Engineering at Biosero, David Dambman leads the software and integrations teams and sets the vision and direction for Biosero’s future software projects. During his eight years at Biosero, David’s leadership has contributed to the development of numerous software products including Green Button Go™. Green Button Go is a device-agnostic software platform that integrates equipment into a cohesive lab ecosystem to automate workflow processes and increase productivity.

As Director of Engineering at Biosero, David Dambman leads the software and integrations teams and sets the vision and direction for Biosero’s future software projects. During his eight years at Biosero, David’s leadership has contributed to the development of numerous software products including Green Button Go™. Green Button Go is a device-agnostic software platform that integrates equipment into a cohesive lab ecosystem to automate workflow processes and increase productivity.

Before joining Biosero in 2011, David worked as a consultant where he honed his software development skills on a variety of large projects including supply chain simulation, aircraft maintenance data visualization, automated test equipment integration and electronic warfare. From 2003 to 2008, David designed and manufactured guitar effects pedals for a company he managed and co-founded.