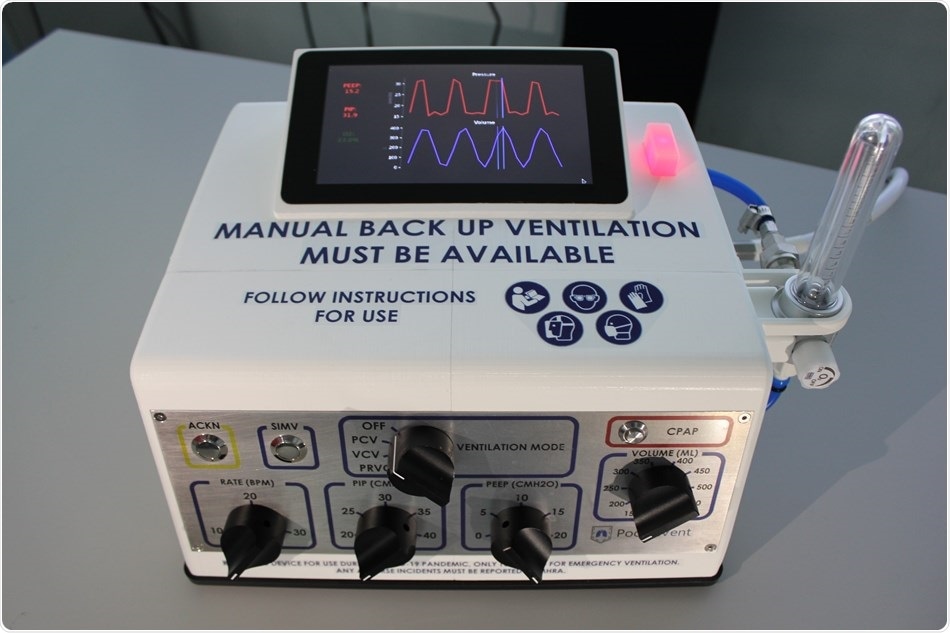

Scientists and engineers from the National Physical Laboratory (NPL) have created a low cost and easy-to-manufacture ventilator design, in response to the need for affordable ventilator technologies in emerging markets. The team at NPL developed several different ventilator prototypes, which led to the design of the PocketVent, a simple to use device that requires limited training time for healthcare professionals and is made from widely available parts.

As COVID-19 developed into a global pandemic, NPL began to utilize its significant capabilities as the UK’s National Metrology Institute, to support several initiatives aiming to combat COVID-19, including the UK Government’s initial call for rapidly manufactured ventilator systems.

As well as designing and developing low cost ventilators, NPL has worked with a number of UK-based organisations to help them understand the performance of their ventilator prototypes, using a dedicated and independent testing facility. The Medicines and Healthcare Products Regulatory Agency (MHRA) issued specification guidance for rapidly manufactured ventilators, and many companies stepped up to begin the manufacturing process. This was often outside their usual scope of expertise, resulting in the need for measurement experts to be on hand to support.

When the Department for International Development (DFID) announced the urgent need for low-cost ventilator technologies in developing economies, NPL was able to build on its testing knowledge to rapidly design its own solution. The PocketVent design:

- Meets the critical functionality and performance requirements detailed in the MHRA specification for ventilation

- Costs approximately £1000 to build – vastly cheaper than a typical ventilator

- Is compact: similar footprint to a laptop

- Low power consumption (approximately 30W)

- Designed to be compatible with pressurized oxygen

- Could be powered from a battery in future

- Can also be operated as a continuous positive airway pressure (CPAP) respiratory device

- Is extensively tested with NPL’s dedicated ventilator test facility

NPL is now looking to share its designs with local manufacturing and healthcare organisations in areas experiencing demand for ventilators, ensuring these devices can be used where they are needed most.

Creating a low cost and easy to produce ventilator in short duration and from a standstill would seem an impossible task, though that is what the NPL Ventilator team have achieved. The foundation of this instrument development has been NPL’s measurement and test capabilities, these were established to support many of the UK’s ventilator development projects. This testing ability at NPL guided the design of the PocketVent which was created by staff within NPL’s Instruments Group. The dedication of the whole NPL Ventilator team during the pandemic has been inspiring.”

Paul Shore, Head of Engineering, NPL

NPL is uniquely placed to test and validate materials, components and sensors, offer guidance on compliance to quality standards and provide access to world leading measurement experts.