Using different UV exposure times and dosages, researchers at the Institute for Biomedical Sciences, Georgia State University, USA, showed that surfaces like glass, plastic, stainless steel, and N95 respirator material could be quickly and easily disinfected of severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), the causative agent of coronavirus disease 2019 (COVID-19).

This news article was a review of a preliminary scientific report that had not undergone peer-review at the time of publication. Since its initial publication, the scientific report has now been peer reviewed and accepted for publication in a Scientific Journal. Links to the preliminary and peer-reviewed reports are available in the Sources section at the bottom of this article. View Sources

This news article was a review of a preliminary scientific report that had not undergone peer-review at the time of publication. Since its initial publication, the scientific report has now been peer reviewed and accepted for publication in a Scientific Journal. Links to the preliminary and peer-reviewed reports are available in the Sources section at the bottom of this article. View Sources

SARS-CoV-2 is mainly spread by airborne transmission of respiratory droplets from infected persons. However, the virus can stay alive for long times on different surfaces, and transmission can occur when people come in contact with such contaminated surfaces (also known as ‘fomites’).

Such spreading from public spaces, hospital rooms, and mass transit vehicles is a cause of concern. Reports have shown that the virus can stay alive on steel or plastic for 72 hours and on cardboard for 24 hours. Hospital rooms where COVID-19 patients have stayed and households with infected persons have shown the presence of viral RNA on various surfaces.

Different methods have been used for cleaning and disinfecting surfaces, including personal protective equipment and masks. Chemical disinfectants and alcohols effectively inactivate SARS-CoV-2, but it can be time-consuming and laborious to clean large spaces. Another method is to use ultraviolet (UV) light, which has been shown to inactivate viruses.

Testing UV for disinfecting surfaces

In a paper published in the bioRxiv* preprint server, researchers from Georgia State University report the efficacy of UV light on inactivating SARS-CoV-2 on different surfaces.

The researchers used a Helo F2 device for their study and first investigated the dose of UV that could be achieved using it. The pulsed device produced 31.14 mJ/cm2 and 103 mJ/cm2 of UV after a minute and 30 minutes of exposure, respectively.

Next, the team spread a suspension of the SARS-CoV-2 virus on glass, stainless steel, polypropylene, and N95 respirator material and allowed it to dry for an hour. The surfaces were then exposed to UV light for different times from a distance of 1 meter.

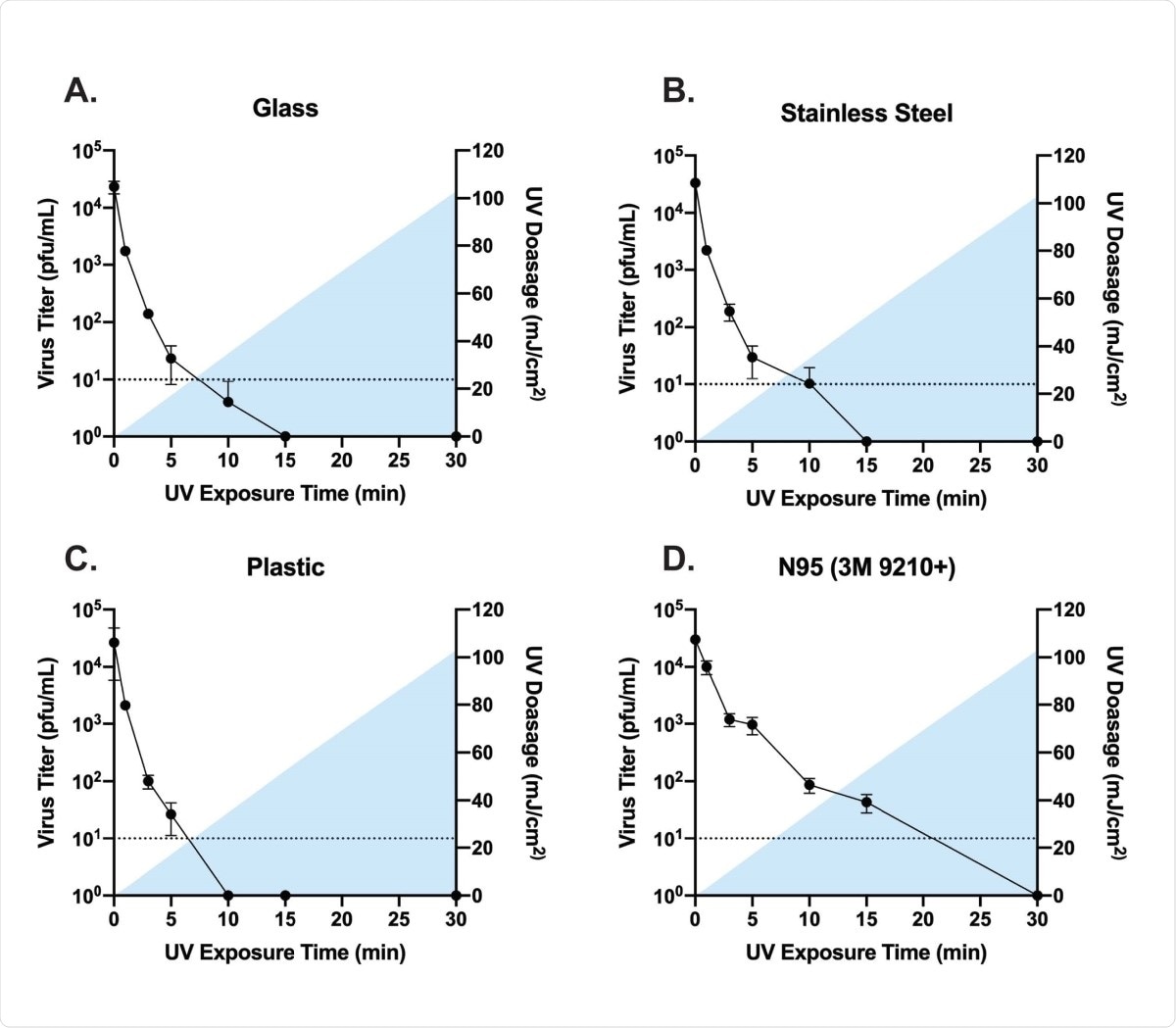

They found that an exposure time of 5 minutes (17.2 mJ/cm2) could reduce the virus counts by 3-log10 fold on the hard non-porous surfaces, glass, stainless steel, and plastic. Doubling the exposure time reduced the virus levels to nearly undetectable levels on glass and plastic, while stainless steel required 15 minutes of exposure.

For the N95 respirator material, 15 minutes of exposure reduced the virus counts 2.86-log10 fold. A 30-minute exposure was required to reduce virus levels to undetectable levels. The higher time required is likely due to the porous and multilayer structure of the material.

The team also tested the use of UV dosimeter cards to ensure the right UV dose has been applied. These cards change color with increasing UV light doses and are easier and cheaper than electronic UV dosimeters.

Using four pieces of dosimeter cards on the four corners during each experiment, the team found that they showed the cards changed color evenly with the different UV doses. They correlated the exposure time, dosage, and viral titer reduction.

Titers of infectious SARS-CoV-2 recovered from UV exposed glass, stainless steel, plastic, and N95 material (A-D). Time 0 represents controls that were not exposed to UV. All timepoints are representative of the mean and standard error of 3 replicates. Blue shading represents the area under the curve for the UV dosage acquired over time. Samples with data points below the limit of detection resulted from a subset of datapoints having undetectable levels of virus. Undetected samples were assigned a value of 1 for graphing purposes.

UV may be an easy disinfection option

Thus, the results suggest broad-spectrum UV light can effectively inactivate the virus on different surfaces with short exposure times. Using UV light for disinfection is advantageous as it is less laborious and prevents close contact of people with contaminated surfaces. Given the shortage of personal protective equipment, disinfection of these materials using UV is also an option. Although how UV affects the protection offered by the materials is not known yet.

A limitation of the study, the authors note, is that they tested the disinfection of surfaces only for a distance of one meter from the UV light. However, using the color-changing dosimetry cards, the dosage required can be theoretically calculated for a given distance or time of exposure, and surfaces can thus be adjusted accordingly.

In addition, the dosimetry cards can be used as an inexpensive method of ensuring the correct dose is applied to a surface to ensure complete disinfection.

This news article was a review of a preliminary scientific report that had not undergone peer-review at the time of publication. Since its initial publication, the scientific report has now been peer reviewed and accepted for publication in a Scientific Journal. Links to the preliminary and peer-reviewed reports are available in the Sources section at the bottom of this article. View Sources

This news article was a review of a preliminary scientific report that had not undergone peer-review at the time of publication. Since its initial publication, the scientific report has now been peer reviewed and accepted for publication in a Scientific Journal. Links to the preliminary and peer-reviewed reports are available in the Sources section at the bottom of this article. View Sources