The severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), the causal agent of the ongoing coronavirus disease 2019 (COVID-19), is a respiratory virus that is primarily transmitted through droplets or aerosols. When a healthy person encounters infected droplets/aerosols, such as those that are generated while talking to or coughing by a SARS-CoV-2 infected individual, they are at an increased risk of contracting the infection.

Importance of antiviral and antibacterial fabrics

Although fabrics serve a wide range of functions, most antiviral and antibacterial fabrics lack systematic research and commercialization. Currently, industries associated with the development of antiviral textile fabrics are experiencing great demand owing to a high requirement for hygienic and clean fabrics. In fact, several studies have shown that the coating of fabrics with certain can prevent transmission of SARS-CoV-2.

Metal-based nanoparticles possess many physicochemical features that allow them to interact with viruses and other harmful microorganisms. For example, gold, copper, silver, titanium, and zinc nanoparticles exhibit wide-ranging antiviral activity, even at a small dose. Antiviral textiles could be manufactured by attaching nanoparticles such as silver, copper, zinc, and zeolite by physical adsorption and ion exchange to textile products.

Metal-organic frameworks (MOFs) act as good carriers of functional nanoparticles when coupled with antiviral elements such as zinc and silver that are subsequently grafted onto the textile. Previous studies have shown that zinc-imidazolate (ZIF-8) MOFs on textile fabrics exhibit promising adsorption capacity for viruses and bacteria, which can be inactivated under light. However, some of the disadvantages of using ZIF-8 MOFs are its high initial mass release, limited durability, and decreased comfort of the fabric.

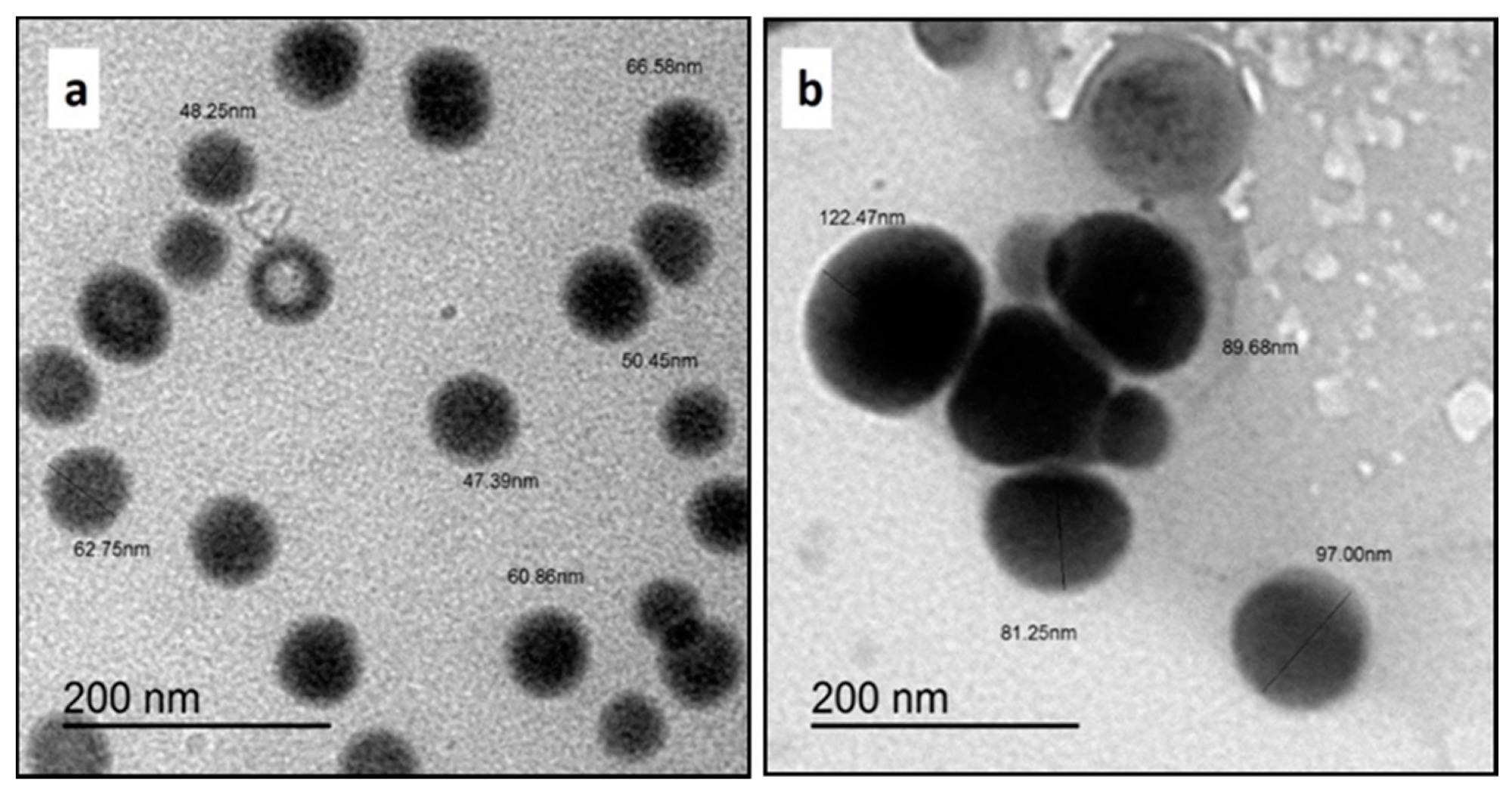

TEM micrographs of SeNPs prepared at different concentrations of (a) 25 mM and (b) 50 mM.

TEM micrographs of SeNPs prepared at different concentrations of (a) 25 mM and (b) 50 mM.

Antiviral selenium nanoparticle polyester fabrics

Selenium (Se) is a metalloid that exists in three well-defined allotropic forms including amorphous, crystalline trigonal with helical chains, and crystalline monoclinic- α, β, γ forms. This element is a photoelectrically active semiconductor that has been applied in solar cell assembly, xerography, and glass production.

Se nanoparticles (SeNPs) exhibit coloring capabilities, along with antimicrobial, antitumor, antioxidant, and antibiofilm properties. Furthermore, SeNPs are associated with low cytotoxicity.

Recently, SeNPs have been explored as antiviral agents for various types of fabrics. To this end, the researchers of a recent Polymers study grafted SeNPs on polyester fabric through a flat screen-printing technique and observed their antimicrobial activity against SARS-CoV-2, Pseudomonas aeruginosa, Bacillus cereus, Salmonella typhi, and Escherichia coli. The researchers subsequently conducted an MTT assay and observed that the printed polyester fabrics with SeNPs have low toxicity toward human skin.

Transmission electron microscopy (TEM) revealed spherical SeNPs that were well-dispersed in a colloidal solution. X-ray diffraction (XRD) analysis confirmed the formation of crystallinity SeNPs and their deposition on the surface of the printed polyester fabric.

The extent of color uptake was expressed by the color strength (K/S) of the blank polyester fabric and printed polyester fabrics with SeNPs using a spectrophotometer. To this end, K/S values of the blank polyester fabric were found to be 0.60, whereas printed polyester fabric with 25 mM SeNPs exhibited a K/S value of 10.68, and 50 nM SeNPs exhibited a K/S value of 8.02.

The maximum color strength was observed at 360 nanometers (nm). The scientists reported a reduction of color strength by 24.91% for printed polyester fabrics with 50nM SeNPs; however, this type of reduction in color strength did not occur in printed polyester fabric with 25 nM SeNPs. This finding might be due to increased positive charges of Se+ ions at higher concentrations of SeNPs that cause high repulsion forces with each other, which leads to a reduction in the ionic bonding process between the polyester fabric and SeNPs.

Printed polyester fabrics treated with 50 mM SeNPs exhibited a darker yellow/brownish color. Upon evaluation of the effect of curing temperature on the color strength of polyester fabrics, both concentrations of SeNPs showed enhanced uptake when the temperature was increased from 160 to 200°C. This might be due to an increase in temperature, which enhanced the nanoparticle's uptake by the fabric and, consequently, the color strength.

Additionally, the authors determined the impact of curing time on the color strength of printed polyester fabrics with SeNPs at various curing time points of three, five, and seven minutes at a constant curing temperature of 200 °C. This experiment revealed that the color strength of both SeNPs concentrations increased in the three-to-five-minute time range and decreased beyond that.

The washing and rubbing fastness of polyester fabrics printed with SeNPs remained outstanding, even after five washes, while lightfastness was found to be good to very good. The SeNP layer significantly decreased severe fabric degradation and supported the retention of fibers within the fabric matrix.

Conclusions

The current study revealed the development of printed polyester fabrics with SeNPs that exhibit significant antimicrobial activity and low cytotoxicity to human skin. The authors of this study are optimistic that SeNP fabric design could have clinical applications in protecting patients against SARS-CoV-2 and other harmful bacteria.

Journal reference:

- Elmaaty, T. A., Sayed-Ahmed, K., Elsisi, H., et al. (2022) Novel Antiviral and Antibacterial Durable Polyester Fabrics Printed with Selenium Nanoparticles (SeNPs). Polymers 14(5). 955. doi:10.3390/polym14050955