Introduction

An orbital mixer’s efficiency is significantly affected by the viscosity of a solution. Commonly used non-aqueous mixing solvents for dyes, vaccines, and drugs are viscous liquids such as glycerol and polyethylene-glycol (PEG). These liquids are also used in protein solutions as stabilizing agents. The performance of a Vitl Co-Mix in mixing solutions containing a higher proportion of glycerol in various tubes and microplates was evaluated in this study.

In the Vitl Co-Mix, a microplate orbital mixer and a tube vortexer are integrated into a single unit, with independent speed controls for every module. It is designed to enable variable speed mixing of different types of readily available multiple-well plates that are commonly used in laboratories. The instrument is equipped with adaptors, which allows for mixing of an array of microtubes, larger tubes and unskirted microplates. The Co-Mix can hold skirted plates without the use of an adapter.

Earlier results have demonstrated easy mixing of aqueous solutions that have a viscosity similar to that of water. Solutions could be mixed within one minute (typically under 10s), irrespective of the well geometry. In this work, the capability of the Co-Mix to effectively mix highly viscous solutions such as glycerol was examined. Glycerol is commonly used in the food and pharmaceutical industries.

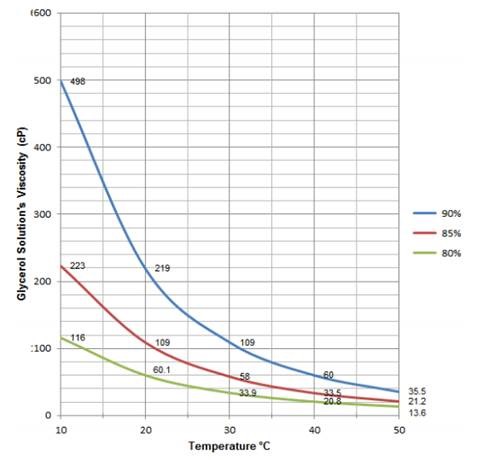

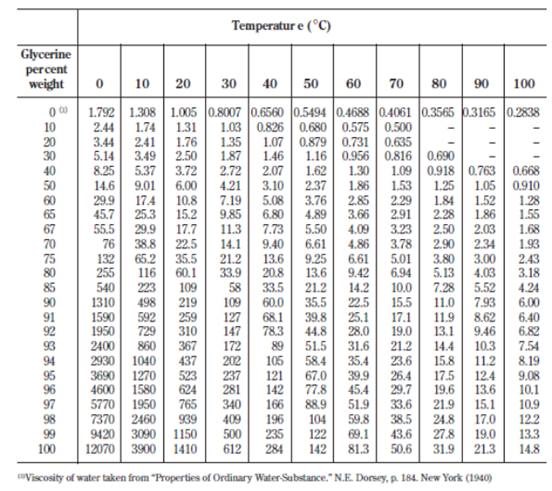

The viscosity of a solution significantly varies with substance, temperature, and concentration. There is a decrease in the viscosity of glycerol with increasing concentration and temperature (Table 1 and Figure 1).

Figure 1. Glycerol Viscosity /oC

Table 1. Viscosity of aqueous glycerine solutions in centipoises/mPa s

Materials and Method

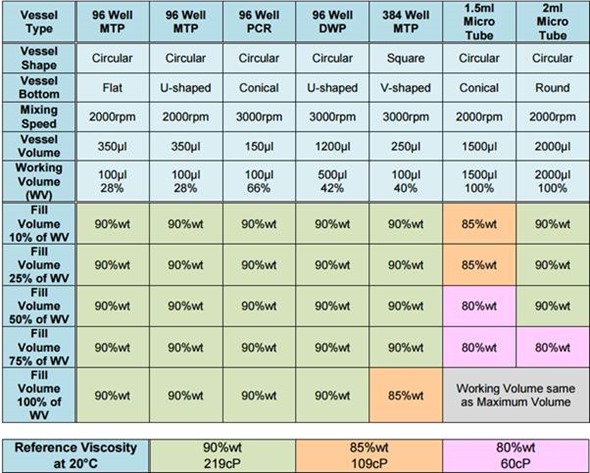

This study evaluated the mixing capability of the Co-Mix for various types of plates and tubes with fill volumes ranging from 10% to 100% of the maximum recommended working fill volume (WV). The study was carried out at a closely controlled ambient temperature of 20-23°C. A glycerol solution in water with a 90%Wt concentration was used as the sample, giving a viscosity of 219cP at 20°C. Ponceau 4R Red Dye was used as the colorant at a ratio of 1 part in 30 by volume.

The same viscosity solution was used for all tests, aside from when the solution failed to completely mix within one minute, in which case a lower viscosity or reduced concentration solution was used and acknowledged in the results. After dispensing the glycerol solution into the sample vessel, it was overlaid by pipetting the red dye. The Co-Mix was used to mix each combination for 60 seconds at the maximum permissible speed and mixing efficiency was visually inspected.

Results

The aim of the tests was to examine the capability of the Co-Mix with highly viscous solutions. The vessel types analyzed, their physical properties, and the achievable mixing viscosity for increasing fill volumes are shown in Table 2. The test results revealed that the mixing efficiency was not significantly affected by the vessel type and fill volume, except for the 1.5ml micro-tubes. The tests showed that the instrument can mix a 90%Wt glycerol solution in the majority of cases, irrespective of sample vessel geometry and fill volumes.

Table 2. Vessel types, physical properties and achievable mixing viscosity for increasing fill volumes

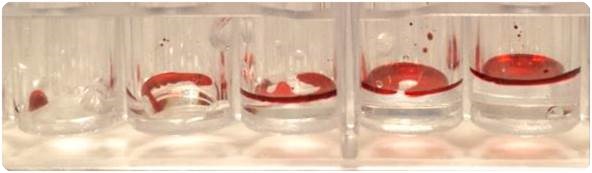

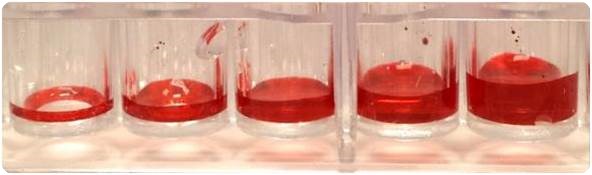

Figures 2 and 3 depict the mixing of the 96 well flat-bottomed microtiter plate at the five glycerol fill volumes of interest and 1:30 dye solution.

Figure 2. 96-well MTP before mixing

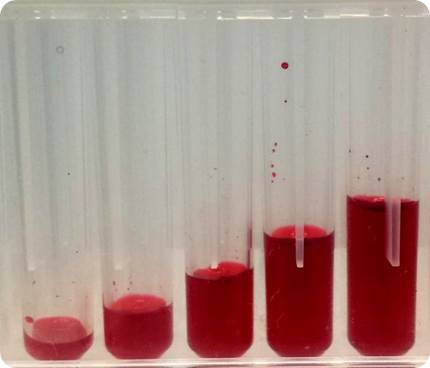

Figure 3. 96-well MTP after mixing

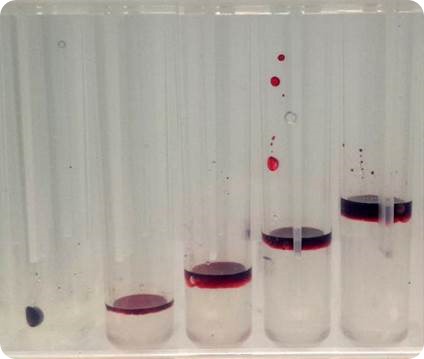

Figures 4 and 5 depict the mixing of the U-shaped 96 well deep well plate at the five fill volumes. The images clearly show the excellent mixing achieved by both the sets of tests within a short space of time, without excessive vertical sample vortexing of the samples.

Figure 4. U-shaped 96-well plate before mixing

Figure 5. U-Shaped 96-well plate after mixing

These are the specifications of the ‘Heated Modules’ used with the Ther-Mix and Flexi-Therm. The Co-Mix has a set of adapters but can mix all microplate types including deepwell plates – the adapters are for unskirted plates and 0.2ml, 0.5ml and 1.5/2ml tubes.

About Vitl Life Science Solutions

Vitl designs, manufactures and sells high quality laboratory instruments to compete with market leaders at an affordable price with unrivalled functionality, usability and style.

The growing Vitl laboratory products range includes the world’s best-selling microplate heat sealer- the VTS and its compact counterpart the MicroTS. Vitl also sell a range of foil and film heat seals as well as microtube pickers and programmable mixers and vortexers.

Vitl products was established in 2006 by the medical, diagnostic and analytical device design and manufacturing company Integrated Technologies Ltd.

As a member of the ITL group, Vitl benefits from the experience and expertise of a parent company that works with globally successful medical devices and laboratory instrumentation.

Vitl products are sold through a global network of distributors and OEM (private label) partners, managed by their main sales offices in the UK, USA and China.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.