The use of nanoparticles in diagnostic and therapeutic applications has expanded in recent years, thanks largely to technological advancement and the growth of research devoted to the topic.

Nanoparticles are under 100 nanometers (nm) in size and have begun taking a more predominant role in how certain interventions are handled. While they aren’t without their risks, nanoparticles provide a number of benefits in medicine.

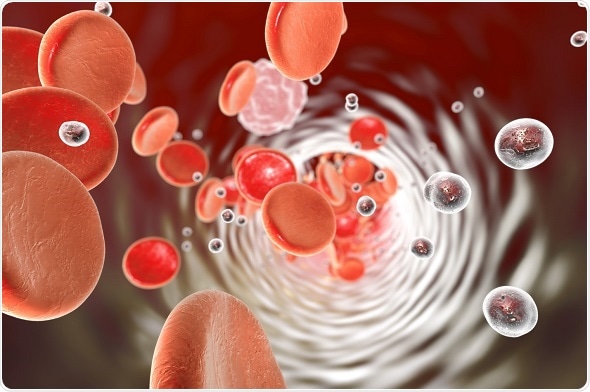

Nanoparticles in blood, 3D illustration. Copyright: Kateryna Kon / Shutterstock.com

Benefits of nanoparticles in medicine

Nanoparticles are tiny vectors that act as carriers of specific substances within the body. They are able to provide a precise treatment dose at the most appropriate time for the most effective benefit.

For instance, nanoparticles can act as carriers for gene and/or drug delivery in tumors, representing a large step in approaching difficult-to-treat cancers.

The main benefits of nanoparticles include:

- Specific targeting of the chosen drug

- Improved safety and potential effectiveness

- Reduced toxicity

Nanoparticles in drug delivery

While there’s some use for nanoparticles in assisting with medical imaging, one of the most popular and effective usages for these particles is drug delivery. Nanoparticles can help reduce toxicity and side effects of drug therapy by delivery to the precise location at a specified time.

For example, nanoparticles carrying chemotherapy drugs to a site within a tumor may be a helpful addition to a cancer treatment regimen. Nanoparticles can also be manipulated in regards to their size, making them versatile for both active and passive drug targeting. Additionally, nanoparticles can be produced to retain the release of a drug during transportation until it reaches the desired location.

Nanoparticle risks and production problems

While the benefits of nanoparticles seem promising, they aren’t without their risks. In regard to the risk for potential nanoparticle toxicity, nanoparticles present a potential societal and environmental impact that must be considered as the technology continues to grow.

Nanoparticles are produced in numerous sizes and shapes; however, producers of these particles tend to favor spherical shapes since these are simpler to synthesize in the laboratory.

The movement toward automation in nanoparticle synthesis

Currently, nanoparticles are mostly produced in small batches due to manual production methods. The lack of automation in the synthesis of nanoparticles has prevented scientists from producing them on a much larger scale due to issues around efficiency and reproducibility.

The move toward automation in the production of medicine has further facilitated studies into how scientists can automate the synthesis of nanoparticles. Once mastered, the automation of nanoparticle synthesis could mean more targeted and effective medicines and therefore reduced treatment costs and improved patient care in many areas of medicine.

A recent process developed by researchers at the University of Southern California (USC) may help automate the manufacturing of nanoparticles, thereby improving the quality and number of nanoparticles made at any given time.

The solution involves creating 3D-printed tubes that are around 250 micrometers in diameter. A parallel network of four tubes are set side-by-side, and a combination of water and oil (or two other non-mixing fluids) are run through the tubes.

These fluids fight to get out of the openings, and in the process they squeeze out tiny droplets which act as chemical reactors that produce nanoparticles. As of now, this method hasn’t been widely adopted. There is hope, however, that this production technique will be refined and expanded as a result of more rigorous study.

Automation won’t necessarily reduce the possible hazards associated with nanoparticles, including inhalation of particles and skin effects associated with dermal exposure. While rare, these issues must be addressed prior to creating larger batches for more consistent patient use.

Automating nanoparticle synthesis

In the preparation and production of nanoparticles, automation provides a more consistent method that can potentially reduce down-stream testing time and improve cost efficiency.

Vitl Life Science Solutions’ Ther-Mix heated mixer removes the variables inherent in manual nanoparticle production methods. These variables include mixing speed, mixing time and temperature. Using a Ther-Mix eliminates the need for stopwatches, thermometers and so forth and replaces them with countdown timers and alerts for completion of mixing.

The deep programmability of the Ther-Mix makes nanoparticle synthesis less time-consuming because you can program several steps in the process i.e. mix at 2000RPM for 10 mins at 30C then keep it at 30 for 1hr without mixing, then spin up again etc. Once created, that user can store up to 100 mixing programs.

How Giorgia uses the Ther-Mix for Nanoparticle Synthesis

The Co-Mix is another useful product that can be used in preparing and testing nanoparticles where heating is not required. This unique laboratory mixer allows users to create and store personalized mixing profiles (up to 100) with different ramp rates, mixing speeds, and mixing times, providing a more efficient production process. Just like the Ther-Mix there is a visual countdown timer and audible system to alert users of the completion of mixing

The Co-Mix also provides stability and improved control at high mixing speeds and incorporates both a tube/plate mixer and a vortex pad which, unlike with any other mixer on the market, can be used simultaneously.

Dr. Vladimir Gubala Discusses the Co Mix

References:

- Shashi K Murthy. Nanoparticles in modern medicine: State of the art and future challenges. Int J Nanomedicine. 2007; 2(2): 129–141.

- Wim H De Jong and Paul JA Borm. Drug delivery and nanoparticles: Applications and hazards. Int J Nanomedicine. 2008; 3(2): 133–149.

- Maureen R. Gwinn and Val Vallyathan. Nanoparticles: Health Effects—Pros and Cons. Environ Health Perspect. 2006; 114(12): 1818–1825.

- Vitl Life Science Solutions. Mass-Production of Nanoparticles in Medicine: Why Aren’t We There Yet? http://www.vitlproducts.com/blog/item/164-mass-production-of-nanoparticles-in-medicine.

- Kurzweil. A practical solution to mass-producing low-cost nanoparticles. http://www.kurzweilai.net/a-practical-solution-to-mass-producing-low-cost-nanoparticles.

About Vitl Life Science Solutions

Vitl designs, manufactures and sells high quality laboratory instruments to compete with market leaders at an affordable price with unrivalled functionality, usability and style.

The growing Vitl laboratory products range includes the world’s best-selling microplate heat sealer- the VTS and its compact counterpart the MicroTS. Vitl also sell a range of foil and film heat seals as well as microtube pickers and programmable mixers and vortexers.

Vitl products was established in 2006 by the medical, diagnostic and analytical device design and manufacturing company Integrated Technologies Ltd.

As a member of the ITL group, Vitl benefits from the experience and expertise of a parent company that works with globally successful medical devices and laboratory instrumentation.

Vitl products are sold through a global network of distributors and OEM (private label) partners, managed by their main sales offices in the UK, USA and China.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.