Researchers often compare efficiency by referring to the highest rotor speed, but this can be misleading because other factors such as temperature or geometry of the tube contribute to the performance of the rotor and should be factored if a valid comparison between similar rotors is going to be made.

Simply owing to the effect of these other factors, certain rotors are more efficient at slower speeds than a similar rotor at higher speeds. As a result, the term k-factor can be used instead of maximum speed, to compare centrifugation labware.

The k-factor is a common parameter describing the efficiency of a centrifuge-rotor system, but temperature is still overlooked. The determination of k-Factor is complicated by temperature, which cannot be applied in a basic formula.

However, it can be managed in programs such as the eXPert software supplied by Beckman Coulter which factors in the temperature and corrects for buffer viscosities.

However, k-factor has all the parameters to replicate a centrifugation step and distinctly defines the ability of a centrifugerotor system, making it an excellent determination for rotor efficiency.

The Determinants of k-Factor

The maximum speed, minimum radius (rmin), and maximum radius (rmax) are the most essential factors contributing to rotor efficiency, all of which contribute to the maximum g-force produced by the rotor.

First, the greater the minimum radius, the greater the centrifugal force at the top of the tube and the faster separation will proceed. In addition, the centrifugal force at the rmin defines a particle’s minimum size for starting sedimentation.

Another factor that directly contributes to rotor efficiency is the total pathlength of the rotor or the difference between minimum and maximum radius.

Shorter pathlengths mean particles do not have as far to travel prior to pelleting against the wall of the tube. Pathlengths in comparable rotors are a function of the sample tube diameter and the angle at which the tube is held.

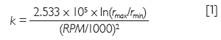

A shorter pathlength generally arises from a more sharply angled tube. k-factor is a simple measure of the overall rotor efficiency that factors in these variables, where:

A lower k-factor corresponds to a more efficient rotor.

Comparative Efficiencies of Two 70,000 rpm Rotors

Interesting results are obtained when the above-mentioned efficiency factors are applied to runs of the Type 70 Ti and Type 70.1 Ti rotors available from Beckman Coulter.

The following example shows how the Type 70.1 Ti rotor at 450,000 x g will pellet the material much more quickly than a Type 70 Ti rotor at a higher RCF (504,000 x g) when both rotors are run at the same rotations per minute (70,000 rpm).

As presented in Table 1, the geometry of the tube cavity in the case of Type 70.1 Ti rotor reduces the rotor’s maximum radius, resulting in a lower g-force, as well as reducing the pathlength of the particles inside the sample tube.

The net effect of this reduced pathlength is a more favorable k-factor for the Type 70.1 Ti rotor, resulting in a pelleting time that is 18% faster than in the Type 70 Ti rotor.

Table 1. Rotor Specifications

|

Rotor Type

|

Type 7G Ti

|

Type 7G.1 Ti

|

|

Maximum speed

|

70,000rpm

|

70,000rpm

|

|

Maximum radius

(rmax)

|

91.9mm

|

82mm

|

|

Minimum radius

(rmin)

|

39.5mm

|

40.5mm

|

|

Maximum g-force

|

504,000 x g

|

450,000 x g

|

|

Total pathlength

|

52.4mm

|

41.5mm

|

|

k-factor

|

44

|

36

|

Bovine serum albumin (BSA) is a protein widely used in research for a variety of purposes. It has a sedimentation coefficient (s) of 4.4s.

For instance, using the previous k-factors calculated (Table 1), if an experimenter employs a Type 70 Ti rotor to pellet BSA, the pelleting time can be calculated as such, where ‘t’ stands for the run time in hours needed to pellet particles of known sedimentation coefficient:

With the help of this basic calculation, researchers can save valuable time and spin the particles for the most efficient duration. When the run time for Type 70.1 Ti rotor is compared with BSA by substituting a k-factor of 36, a time of 8h, 11min is generated, showing that a rotor with a smaller maximum g-force can indeed be more efficient.

Relating Run Time Between Labware

The SW 28 and the SW 32 Ti are popular and high-performance rotors from the Beckman Coulter portfolio.

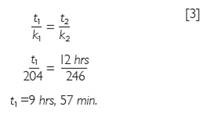

To compare the run times between two rotors in order to duplicate a certain centrifugation step, all a researcher needs to know is the k-factor of each rotor and the run duration from a previous technique. The following equation can be used for this purpose:

where k1 is the k-factor of the SW 32 Ti rotor and k2 is the k-factor of the SW 28 rotor; t2 is the run duration of a previous method, and t1 refers to the unknown spin time for the SW 32 Ti rotor.

This is another simple calculation that aids researchers when comparing techniques between two different centrifuge rotor systems. This equation helps to sediment particles equally and compares efficiency among labware.

As mentioned before, a rotor’s k-factor is determinant upon the pathlength of the standard tube for the given rotor. If a researcher has to use a specific rotor geometry and maximum g-force, it is still possible to improve k-factor by reducing the pathlength.

One such example is the application of Beckman Coulter’s g-Max tubes. This novel system uses patented Quick-Seal bell-top polyallomer tubes and floating spacers.

The g-Max spacers, unlike traditional sleeve type adapters, float on top of the tube and the sample is maintained at the maximum radius of the tube cavity - shortening the pathlength of the standard tube for the specified rotor - thereby enabling users to run smaller sample volumes without g-force being reduced.

The duration of the run can be reduced in those rotors where g-Max tubes correspond to a shorter pathlength and smaller k-factor, which saves critical time. The g-Max tubes can be used with most Beckman Coulter ultracentrifuge rotors.

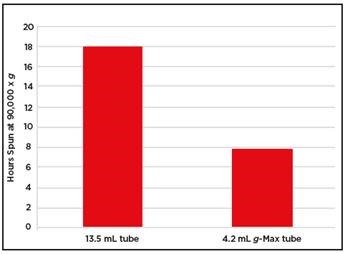

In Figure 1, the g-Max technology shows the significant time savings afforded by using different labware. In the case of the Type 90 Ti rotor, the k-factor of a 4.2 mL g-Max tube is 11 compared with a 13.5 mL tube with a k-factor of 25, both spun at 90,000 rpm.

Figure 1 shows an example of g-Max technology resulting in a 56% time saving between the two tubes. An overnight spin of 18 h is needed for the majority of applications.

Figure 1. Comparative efficiency of g-Max technology. Image credit: Beckman Coulter

However, equivalent separations are achievable in less than 8 h with the g-Max tube, which is more suited to a typical work day and generates a more convenient workflow.

k-Factors and Large-Scale Vaccine Production

k-factors not only affect the pelleting time of ultracentrifuges, but of all types of centrifuges, as previously mentioned. The example given below shows how k-factor affects the efficiency of rotors in high-performance centrifuges.

The large-scale production of vaccines to fight widespread plagues and eliminate diseases worldwide, is critical to the human race. In a large number of cases, high-capacity centrifugation is used to harvest cells, at speeds of about 5,000 x g.

This application has traditionally been carried out in swinging bucket rotors, but high throughput is essential to researchers, to increase yield and reduce the time to market.

Table 2 shows that the J-LITE JLA-9.1000 and the J-LITE JLA-8.1000 rotors from Beckman Coulter are well-designed and reduce the k-factor while processing large volumes in just one spin.

Table 2. Comparison of High-Capacity Fixed Angle 1-Liter Rotors

|

Rotor

|

J-LITE JLA-8.1000

|

J-LITE JLA-9.1000

|

Fibrolite™ F9-6 x

|

Fibrolite F8-6 x

|

Fibrolite F5-10 x

|

Fibrolite F6-6 x

|

|

1,000 LEX

|

1,000y

|

1,000 LEX

|

1,000y

|

|

Type

|

Fixed-Angle

|

Fixed-Angle

|

Fixed-Angle

|

Fixed-Angle

|

Fixed-Angle

|

Fixed-Angle

|

|

Maximum volume (mol)

|

6x1,000

|

4x1,000

|

6x1,000

|

6x1,000

|

10x1,000

|

6x1,000

|

|

Maximum speed (rpm)

|

8,000

|

9,000

|

9,000

|

8,500

|

5,500

|

6,000

|

|

Minimum radius (mm)

|

119

|

82

|

65

|

54

|

124

|

54

|

|

Maximum radius (mm)

|

222.8

|

185

|

194

|

196

|

275

|

196

|

|

Maximum g-force

|

15,970 x g

|

16,800 x g

|

17,568 x g

|

15,900 x g

|

9,333 x g

|

7,900 x g

|

|

Total path length (mm)

|

103.8

|

103

|

129

|

142

|

151

|

142

|

|

k-factor with largest volume at max speed

|

2,482

|

2,540

|

3,415

|

5,096

|

6,662

|

9,060

|

The fact that low k-factors correspond with high-efficiency saves valuable time and reduces electricity costs and rotor wear.

Also, during the production of vaccines, following the initial cell pelleting step, speeds of 15,000 x g are needed to purify the pathogenic virus antigens, something that both of the 1-liter high-capacity rotors from Beckman Coulter are capable of, thereby adding functionality to rotors that are already efficient.

Using Beckman Coulters high-performance rotors, manufacturers can enhance their process performance, shorten time to market, and minimize costs.

About Beckman Coulter

About Beckman Coulter

Beckman Coulter develops, manufactures and markets products that simplify, automate and innovate complex biomedical tests. More than a quarter of a million Beckman Coulter instruments operate in laboratories around the world, supplying critical information for improving patient health and reducing the cost of care.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.