Importance of Technique

Any material used in a medical device should have a strong structure and suitable mechanical properties but be biologically inert, or preferably evoke a healing response within the body. To achieve this need for strength and durability combined with biocompatibility, surface treatments such as bonded coatings are often adopted.

These may increase the lubricating properties, hydrophobic or hydrophilic activity, and compatibility with the body, as seen with the use of heparin to coat coronary stents and thus bring down the frequency of thrombosis and restenosis at the stent site. Catheters are often coated with hydrogels to make them easy to insert, by increasing their lubricity, without making it difficult to handle them before insertion.

Before a coating is used the manufacturer must know how it will act on a surface. This is difficult to accomplish with techniques such as traditional electron microscopy, when dealing with thin coatings applied to insulative samples. The use of a high vacuum in electron microscopes requires complete dehydration of the sample, and this means that hydrogels, over 80 percent of which is constituted by water, are not suitable for this technique.

Atomic force microscopy, AFM, is another technique, however, which is ideal for studying coatings on conductors and non-conductors alike, as well as dry or wet samples. Analysis of samples by AFM imaging leads to the obtaining of high-resolution topographic details which other techniques cannot provide.

Results

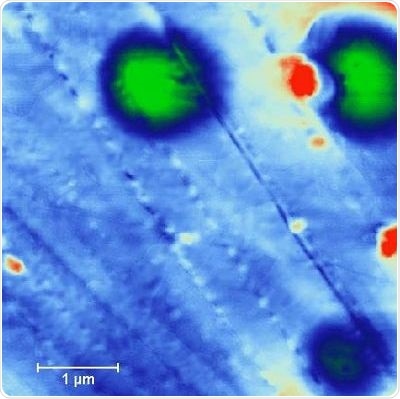

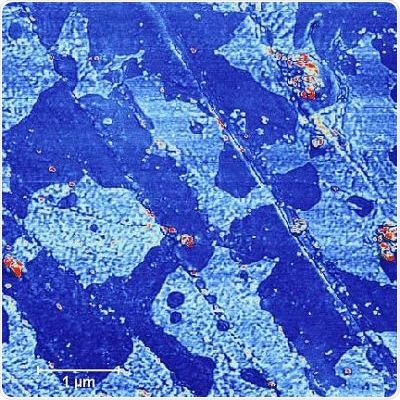

In Figure 1, a polyurethane tube coated with a high-lubricity hydrogel is shown as to its surface topography. The area studied measured 5µm x 5µm. The colors indicate the height of the spot from the sample surface. Dark blue indicates a sunken area while red indicates a raised area, with 100 nm being the range of height. Figure 2 shows a phase image covering the same area of study, taken at the same time as Figure 1.

This type of image shows the lag in phase of the oscillating cantilever with relation to the driving force, as a change in the lateral position. The phase lag responds to differences in the sample’s material properties. For instance, in this image, the coating is seen to vary in physical characteristics in differing areas, but these are not seen well in the first figure which shows the height image of the tube.

Figure 1. Topographic Image of Coated Tube

Figure 2. Phase Image, same area as Figure 1

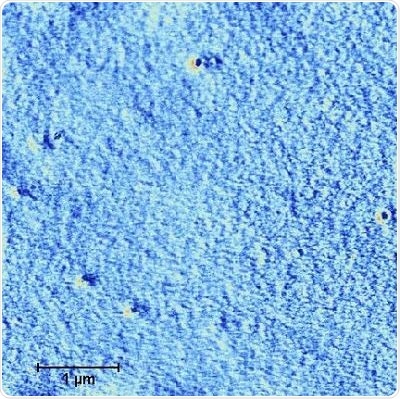

Moistening the tube causes the surface to become very even, as Figure 3 shows. This shows how water addition changes the tube coating properties completely. The image shown in Figure 3 is taken at ordinary settings, but it could have been taken under fluid. The unique advantages of AFM among other analytical techniques include:

- High-resolution imaging

- Detailing physical as well as topographical characteristics

- Imaging of insulating samples

- Images of samples under both ambient and controlled conditions

- No sample preparation is needed

Figure 3. Phase image, tubing after being moistened

About EAG Laboratories.

About EAG Laboratories.

How do you make a product better, easier to use or less expensive? How do you ensure regulatory compliance or strengthen your legal case? How do you bring powerful scientific know-how across materials sciences, engineering sciences and life sciences to your commercial challenges? Ask EAG. We Know How.

A Global Scientific Services Company

More than ever before, the world is experiencing a powerful convergence of science, technology and commerce. Great scientific minds are driving awe inspiring commercial initiatives, and companies around the globe are seeking the insight and competitive advantage that advanced science can provide.

With deep experience across materials sciences, engineering sciences and life sciences, EAG is at the forefront of this revolution, one that is changing the way products are developed, designed, manufactured and used by millions of people around the planet.

EAG Laboratories brings together the most respected names in contract research and testing services to strengthen our multi-disciplinary expertise. So whether your challenge is to accelerate research and development, solve manufacturing problems or ensure compliance with industry and governmental regulations, there’s always one answer. Ask EAG. We Know How.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.