The resolution of microscopies of all types is limited due to ambient vibration. It reduces the localizability of features in clear and obvious ways — this is a growing issue for the long acquisition times and declining scale of today’s imaging applications.

What may not be clear is the interactions of mechanical, seismic, cable-borne, and acoustic stimuli. Bolting equipment to a conventional air table is not sufficient to achieve today’s nanoscale stability standards.

This article outlines various isolation approaches – from the basic to the more sophisticated – suggesting productive strategies for mitigation and spotlighting under appreciated contributors to system instabilities.

Conventional air isolators

Since the 1970s, the air table has been a frequently applied tool when it comes to improving stability. The table-top is supported by a pressurized diaphragm while offering a low-friction, weak-spring support that attenuates high-frequency vibration from the floor.

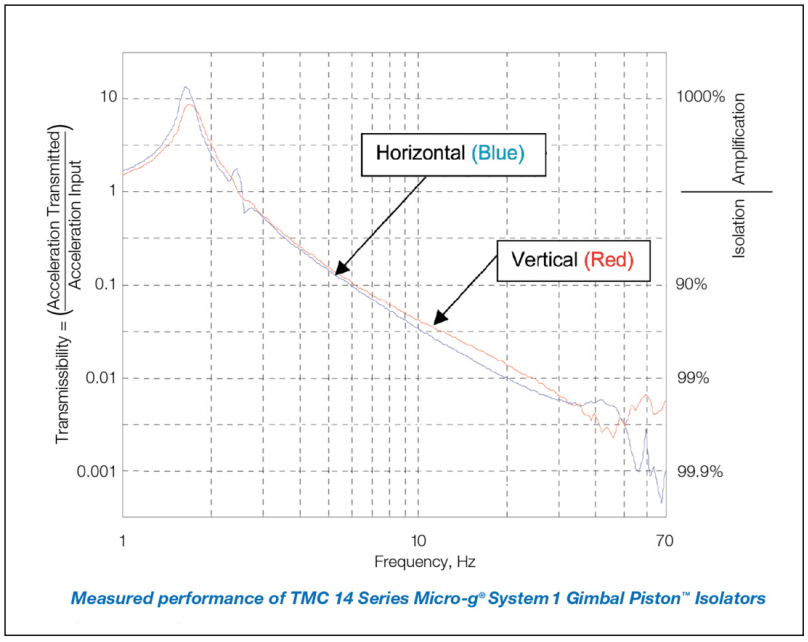

As a result, the spring-mass system displays a transmissibility curve with a general resonant frequency (Fres) of 1-3 Hz, amplifying spectral components close to these frequencies, as displayed in Figure 1.

Figure 1. Conventional air isolator transmissibility curve.

Image Credit: TMC Vibration Control

Piezo technology addresses low-frequency transmissibility and amplification

Air isolators offer excellent attenuation of high-frequency components of floor vibration, but they can be problematic when it comes to their transmission of low frequencies and amplification at Fres in the 1-3 Hz range in relation to advanced imaging techniques.

Luckily, the piezoelectric technology that delivers responsive nano-actuation and long-term stability of sample positions, objectives and scanning probes1 has been applied in specialized isolators that nullify low-frequency transmitted floor excitation actively.

In these completely active vibration cancellation systems, sensors monitor and measure floor vibration on a continuous basis, and the piezoelectric devices contract and expand to transmit canceling forces in real-time under digital control.2

Figure 2. High-force piezo stacks.

Image Credit: TMC Vibration Control

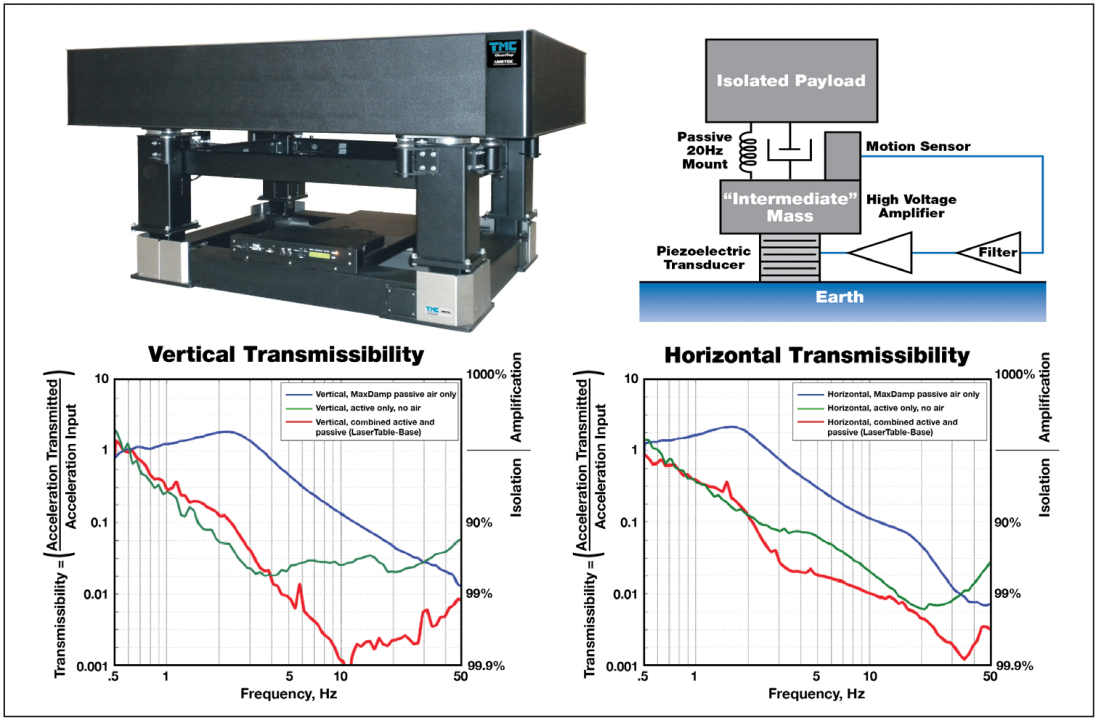

In a novel hybrid approach for sophisticated microscopies, highly-reliable piezoelectric active nullification technology is paired with pneumatic isolation elements to deliver excellent combined isolation.

In this method, the power of each technology is leveraged: the piezoelectric active isolation tackles the issue of transmissibility and amplification while the pneumatic element addresses the inevitably finite bandwidth of the active isolation technology. See Figure 3.

Figure 3. Comparative transmissibility’s for passive vs. hybrid isolation.

Image Credit: TMC Vibration Control

The floor is only one source

Tables are resonant frameworks by default. Damping elements incorporated into better models can limit their response to stimulus, whether a residuum of floor vibration through isolators or from acoustic, cable-borne or onboard sources, including fans and transformers. Mitigation strategies include:

- Leverage structural node

- Reduce coupling of acoustic room-modes

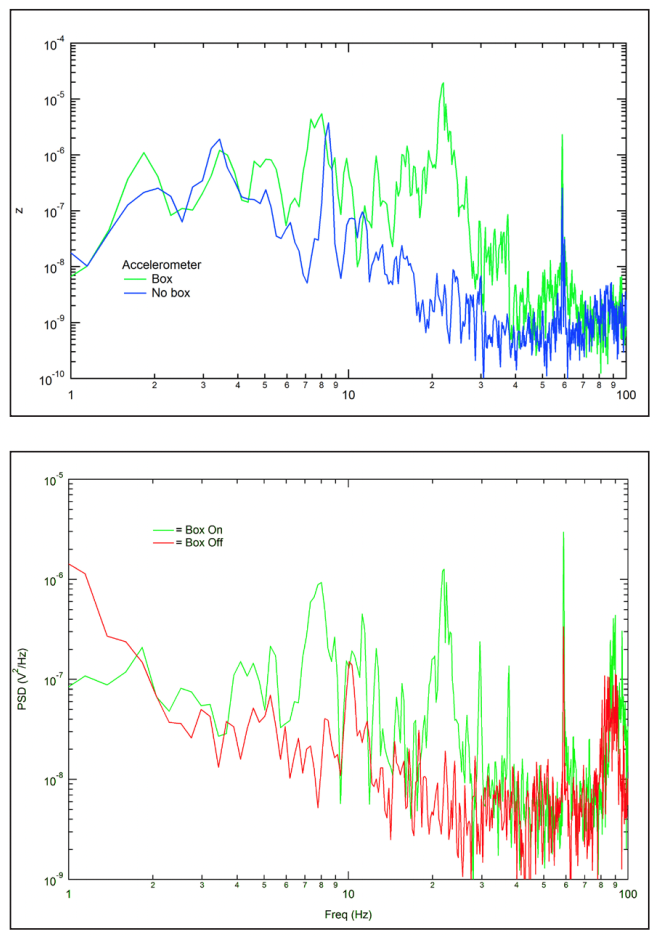

Figure 4. Before/after quiescent spectra of an advanced microscopy apparatus with “isolation box” attached or removed from the table-top [4]. Top: accelerometer data. Bottom: Data observed at AFM tip.

Image Credit: Thomas Perkins, JILA, National Institute of Standards and Technology and University of Colorado, Boulder.

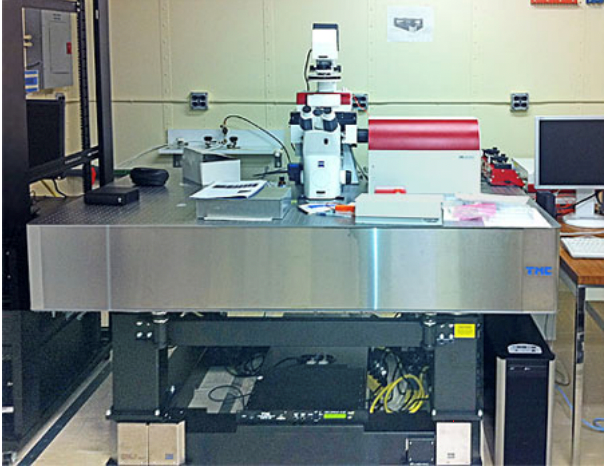

Additional application photos of LaserTable-Base™

Image Credit: IBM Corporation

Image Credit: Uppsala University

References

- Jordan, S. And Anthony, P., Curr. Pharm Biotechnology, 2009, 10, 515-521

- Yuan Shen et al., 2013, Advanced Materials Research, 706-708, 1423

- Abbondazieri et al, Nature, Nov. 24, 2005, 438(7067): 460-465.

- The authors thank Thomas Perkins for contributing this vivid before/after data.

Technical Manufacturing Corporation Vibration Control

TMC’s precision floor vibration isolation systems product line ranges from simple, desktop isolated microscope bases, to any size optical top, to sophisticated active, inertial vibration cancellation systems featuring piezoelectric actuators and digital controllers.

Their latest innovations include STACIS 2100, STACIS® iX SEM-Base™, STACIS® iX Stage-Base™, STACIS® iX LaserTable-Base™, and Mag-NetX™ magnetic field cancellation systems.

TMC is the leader in precision floor vibration isolation technology. Their customers include major research centers, OEM and end-user semiconductor manufacturers, university research laboratories, drug discovery companies, and nanotechnology labs.

With few exceptions, their product line has been designed and manufactured at TMC. With vertically integrated manufacturing, they can make complex mechanical structures quickly and cost effectively.

No time is lost in misinterpreting specifications and quality expectations. Many of their products are custom manufactured for OEM and end users. One of the major advantages of making everything at TMC is that tools such as 3D engineering models can go directly to our factory floor without missteps and delays.

TMC is now part of AMETEK, a leading global manufacturer of electronic instruments and electro-mechanical devices. TMC joins AMETEK as part of the Ultra Precision Technologies division of AMETEK EIG.

Ultra Precision Technologies is a pioneer in the development of ultra precision measurement instruments and a global leader in ultra precise machine tools and manufacturing systems for the semiconductor, photovoltaic, nanotechnology, military, defense, and ophthalmic lens markets.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK has approximately 11,600 colleagues working at more than 100 manufacturing facilities and more than 100 sales and service centers in the United States and around the world.

Now part of AMETEK, they remain TMC. The same people in the same location committed to pioneering our field by designing and manufacturing the most advanced precision floor vibration isolation systems commercially available.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.