Introduction

Contemporary technology and equipment, originally designed in the late 1970s, have given way to more sophisticated methods and more flourishing protocols. In vitro fertilization, popularly known as IVF, is a unique kind of assisted reproductive technology (ART).

Challenge

When embryos and oocytes are subjected to ART, they should not experience any vibration as they can be easily damaged. Fertility procedures like preimplantation genetic diagnosis (PGD) and preimplantation genetic screening (PGS), and sophisticated IVF methods namely, assisted hatching (AHA) and intracytoplasmic sperm injection (ICSI), need accurate movements and an environment free from vibrations.

Discussion

Syracuse, New York-based CNY Fertility Center, situated about ½ miles from the Interstate, was affected by vibrations in the building. These vibrations would also have been caused by numerous laboratory instruments like purging gas flow meters and benchtop incubators that were placed in close proximity.

Ambient building vibration and foot traffic around and within the laboratory could have been other potential sources of vibrations. However, irrespective of the source, all vibrations present potential risk for disruption and damage in the ART laboratory.

Nevertheless, safe micromanipulation techniques can be practiced by using active vibration cancellation and thus, ensure a successful procedure.

Solution: TMC Everstill™ K-400

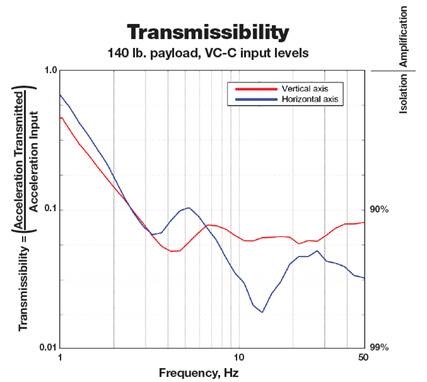

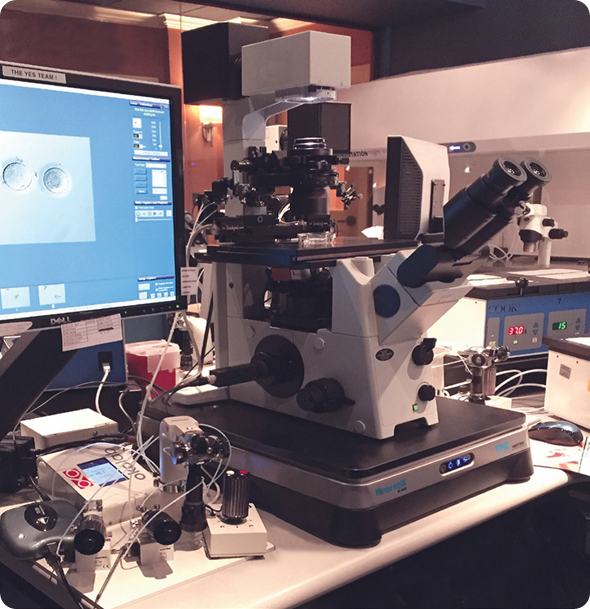

The Everstill K-400 is designed to offer excellent vibration cancellation, thereby enabling a safe micromanipulation environment (Figure 1). Aggressive low frequency vibration isolation combined with a steady surface for the Olympus IX71 microscope was provided by the serial type active vibration control technology (Figure 2). Installation is also made relatively easy, and the system can be self-leveled simply at the press of a button.

Figure 1. TMC Everstill™ K-400

Figure 2. The serial type active vibration control technology provided aggressive low frequency vibration isolation with a stable surface for the microscope.

Advantages of TMC Everstill™ K-400

In the ICSI video, vibrations in the environment can be clearly seen in the oocyte image. A successful procedure cannot be executed even when low-amplitude vibration is present.

Everstill App Note

Such vibrations can arise from the floor and through the laboratory table. When the Everstill K-400 unit was switched on after 35s, the vibration was fully eliminated and the process continued. The Olympus IX71 microscope, supported by the Everstill K-400 unit, now allows the clinic to carry out all micromanipulation methods in a safer and more efficient manner (Figure 3).

Figure 3. TMC Everstill™ K-400

Benefits of the Everstill K-400 are as follows:

- Low frequency vibration cancellation

- Simple operation

- Easy installation

- Hard mount design

- Automatic leveling

- Air is not needed

Technical Manufacturing Corporation Vibration Control

TMC’s precision floor vibration isolation systems product line ranges from simple, desktop isolated microscope bases, to any size optical top, to sophisticated active, inertial vibration cancellation systems featuring piezoelectric actuators and digital controllers.

Their latest innovations include STACIS 2100, STACIS® iX SEM-Base™, STACIS® iX Stage-Base™, STACIS® iX LaserTable-Base™, and Mag-NetX™ magnetic field cancellation systems.

TMC is the leader in precision floor vibration isolation technology. Their customers include major research centers, OEM and end-user semiconductor manufacturers, university research laboratories, drug discovery companies, and nanotechnology labs.

With few exceptions, their product line has been designed and manufactured at TMC. With vertically integrated manufacturing, they can make complex mechanical structures quickly and cost effectively.

No time is lost in misinterpreting specifications and quality expectations. Many of their products are custom manufactured for OEM and end users. One of the major advantages of making everything at TMC is that tools such as 3D engineering models can go directly to our factory floor without missteps and delays.

TMC is now part of AMETEK, a leading global manufacturer of electronic instruments and electro-mechanical devices. TMC joins AMETEK as part of the Ultra Precision Technologies division of AMETEK EIG.

Ultra Precision Technologies is a pioneer in the development of ultra precision measurement instruments and a global leader in ultra precise machine tools and manufacturing systems for the semiconductor, photovoltaic, nanotechnology, military, defense, and ophthalmic lens markets.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK has approximately 11,600 colleagues working at more than 100 manufacturing facilities and more than 100 sales and service centers in the United States and around the world.

Now part of AMETEK, they remain TMC. The same people in the same location committed to pioneering our field by designing and manufacturing the most advanced precision floor vibration isolation systems commercially available.