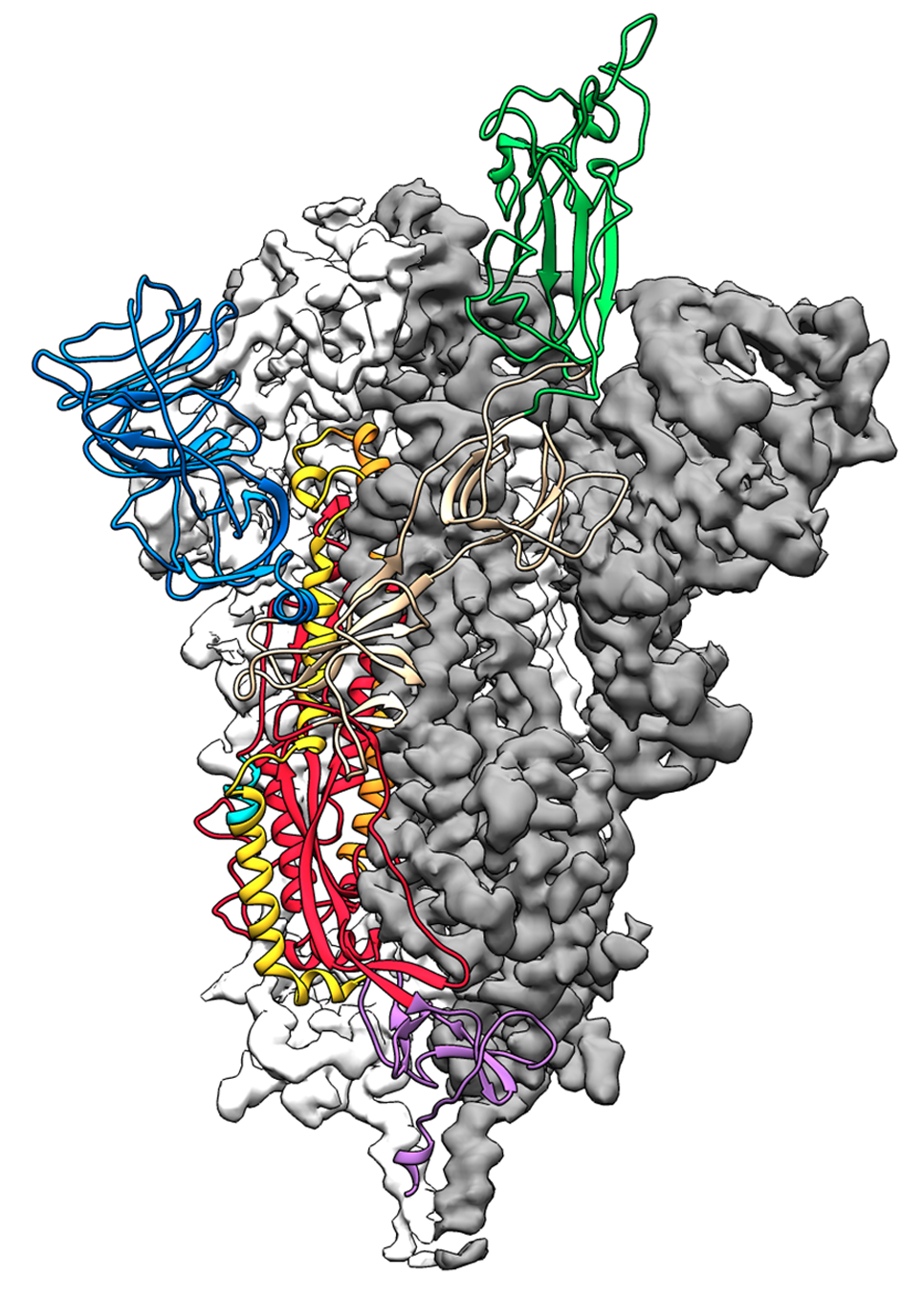

On February 19th, 2020, researchers at the University of Texas at Austin and the National Institutes of Health declared the creation of the first 3D molecular structure of the part of the 2019 novel coronavirus1 that binds to and infects human cells. This was a key milestone for the design of vaccines and other interventions.

Image Credit: TMC Vibration Control

To generate the atomic-scale 3D models, the researchers used two Thermo Fisher Scientific Cryogenic Transmission Electron Microscopes (Cryo-TEMs) – a Krios and a Talos – fitted with with Gatan K3™ single electron counting direct detection cameras.2

The Sauer Structural Biology lab that is home to the Cryo-TEMs is located centrally on the UT Austin campus in the Faulkner Nanoscience and Technology Building, approximately one mile from the I-35 highway; nearby heavy traffic is a frequent source of excessive floor vibration.

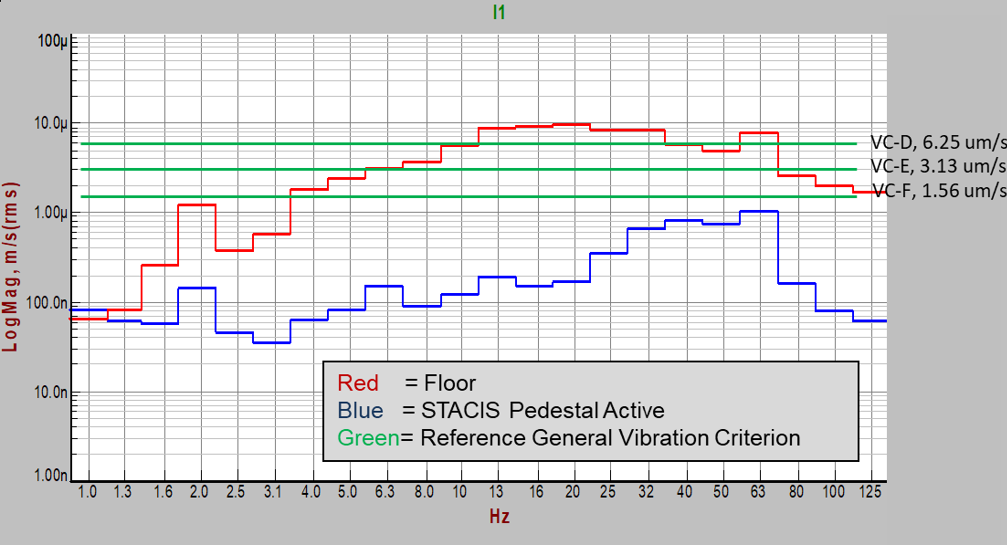

As expected, the survey conducted early in the planning stage established that the vibration at very low frequencies was above the requirements for one of the microscopes.

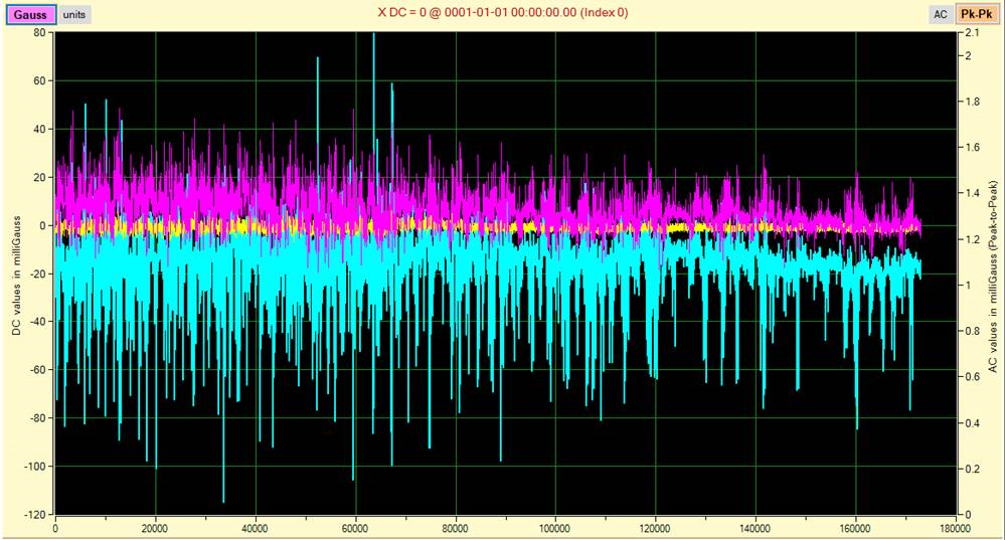

Additionally, AC magnetic field levels were higher than the instrument specifications, which is a normal occurrence in a multi-use facility. Elevator activity in the vicinity would cause an occasional shift in quasi-DC fields, again going beyond the manufacturer's specifications for the TEMs as well as the Gatan K3 cameras.

Figure 1. Typical setup of a Krios TEM on a STACIS Quiet Island.

Image Credit: TMC Vibration Control

To correct these environmental disturbances, for each TEM, TMC fitted a STACIS Quiet Island active floor vibration cancellation system on the floor under the Talos and Mag-NetX active magnetic field cancellation systems.

The floor of the room was designed to be compatible with the Quiet Island concept, which enabled the installation of the TEM without being raised above floor level.

As displayed in Figure 2, the STACIS Quiet Island, with a novel piezoelectric vibration cancellation technology, is able to suppress the floor vibration from above Vibration Criterion level D to below level F.3

Figure 2. Actual room floor vibration measurements at the site under the Talos.

Image Credit: TMC Vibration Control

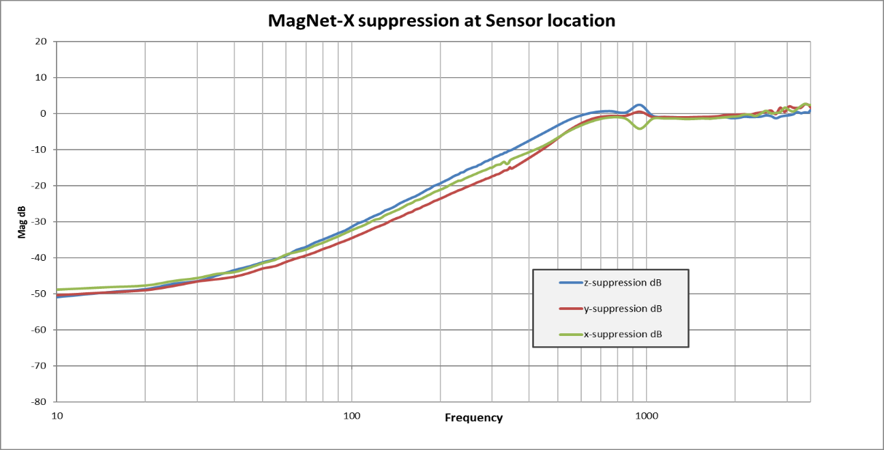

TMC’s inside-out knowledge of the Thermo Fisher Cryo-TEMs facilitated the integration of Mag-NetX systems’ Helmholtz coils into the TEMs’ enclosures, making good use of the valuable space in the room.

The enclosure-mounted active field cancellation system offers around 100x suppression of magnetic fields at the sensor (see Figure 4). The Mag-NetX controller and GUI can also be continuously deployed to monitor fields (attenuated fields, or in “open-loop”) and transmit data in terms of field strength over time (see Figure 3) or even plotted against frequency.

Figure 3. TMC’s Mag-NetX system can be used to continuously monitor the fields. This allows the user to monitor for changes in the environment throughout the day. This is an example of a recording over a period of 9.5 hours at a different city location before the system was powered.

Image Credit: TMC Vibration Control

Figure 4. Actual measurements of magnetic field suppression at the sensor location (usually close to the microscope’s stage).

Image Credit: TMC Vibration Control

Because of the pump and transmitter downstairs, the initial site survey for our facility didn't pass. So we purchased the STACIS and Mag-NetX from TMC to counteract the vibration and EMI issues. The microscopes work pretty well after the installation of these two items, and is very stable because of the cancellation of vibration and extra EMI,"

Aguang Dai, PhD, Lab Manager, Sauer Structural Biology Laboratory, University of Texas at Austin

TMC’s technology and expertise offered state-of-the-art solutions that met the demands of these high-performing microscopes and cameras in complex and demanding environments.

TMC’s modular design approach facilitates the pairing of standard components and design concepts in engineered, tailored solutions to be compatible with the unique geometry of Cryo-EMs.

References

- Breakthrough in Coronavirus Research Results in New Map to Support Vaccine Design", Feb 19, 2020,

- K3 Camera page on Gatan website

- Evolving criteria for research facilities: I – Vibration, Colin Gordon Associates, SPIE Conference 5933: Buildings for Nanoscale Research and Beyond, 2005

Technical Manufacturing Corporation Vibration Control

TMC’s precision floor vibration isolation systems product line ranges from simple, desktop isolated microscope bases, to any size optical top, to sophisticated active, inertial vibration cancellation systems featuring piezoelectric actuators and digital controllers.

Their latest innovations include STACIS 2100, STACIS® iX SEM-Base™, STACIS® iX Stage-Base™, STACIS® iX LaserTable-Base™, and Mag-NetX™ magnetic field cancellation systems.

TMC is the leader in precision floor vibration isolation technology. Their customers include major research centers, OEM and end-user semiconductor manufacturers, university research laboratories, drug discovery companies, and nanotechnology labs.

With few exceptions, their product line has been designed and manufactured at TMC. With vertically integrated manufacturing, they can make complex mechanical structures quickly and cost effectively.

No time is lost in misinterpreting specifications and quality expectations. Many of their products are custom manufactured for OEM and end users. One of the major advantages of making everything at TMC is that tools such as 3D engineering models can go directly to our factory floor without missteps and delays.

TMC is now part of AMETEK, a leading global manufacturer of electronic instruments and electro-mechanical devices. TMC joins AMETEK as part of the Ultra Precision Technologies division of AMETEK EIG.

Ultra Precision Technologies is a pioneer in the development of ultra precision measurement instruments and a global leader in ultra precise machine tools and manufacturing systems for the semiconductor, photovoltaic, nanotechnology, military, defense, and ophthalmic lens markets.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK has approximately 11,600 colleagues working at more than 100 manufacturing facilities and more than 100 sales and service centers in the United States and around the world.

Now part of AMETEK, they remain TMC. The same people in the same location committed to pioneering our field by designing and manufacturing the most advanced precision floor vibration isolation systems commercially available.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.