Industrial, environmental, and medical devices rely on pumps for a wide range of applications. Among the many pump types available, piston pumps and peristaltic pumps are frequently compared due to their distinct operating mechanisms and suitability for different tasks.

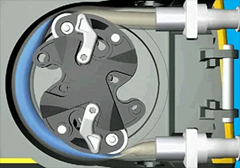

Image Credit: Fluid Metering, Inc.

In this article, we’ll highlight the advantages of Fluid Metering’s valveless piston pumps over peristaltic pumps, focusing on their low maintenance requirements and exceptional repeatability—key factors that make them a preferred choice.

Precision and Accuracy

One of the most important benefits of Fluid Metering piston pumps is their precision. Known for their capacity to distribute fluids with great accuracy and consistency, their precision is especially critical in applications where even minor deviations in fluid administration can have serious repercussions, such as medical dosage or chemical processing.

On the other hand, the repeated squeezing and releasing of the peristaltic pump tubing diminishes its precision over time and increases pulsation, making it unsuitable for several applications.

High Pressure Capabilities

Fluid metering pumps can produce much higher pressures than peristaltic pumps. This makes them perfect for applications requiring high-pressure delivery, such as hydraulic systems and high-pressure cleaning.

Unlike piston pumps, which can handle these demanding jobs without compromising performance, peristaltic pump designs have a maximum flow rate limit.

Durability and Longevity

Fluid Metering's valveless piston pumps are more durable and have fewer moving parts than peristaltic pumps.

Fluid Metering piston pumps are often made of materials that can withstand harsh conditions and abrasive fluids, making them a dependable choice for long-term use in medical settings.

Due to the pressures and wear on peristaltic pump tubes, they often require replacement anywhere from a few hundred hours to several thousand hours of operation.

Versatility in Fluid Handling

Fluid Metering piston pumps can handle a variety of fluids, such as those with varying viscosities and abrasive particles. This versatility makes them suitable for diverse applications.

However, peristaltic pumps tend to struggle with highly viscous fluids or those containing solid particles, which limits their applicability.

Efficiency and Performance

Another strong reason to use piston pumps is their efficiency. These pumps are designed to reduce energy loss while increasing fluid delivery efficiency.

This not only reduces costs over time but also provides consistent performance even under changing operational conditions. Peristaltic pumps, while helpful in some situations, consume more energy and have lower efficiency due to friction between the tube and rollers.

Reduced Maintenance

Fluid metering piston pumps usually require less frequent maintenance than peristaltic pumps. The design of Fluid Metering piston pumps lowers wear and strain on components, resulting in fewer breakdowns and downtime.

In contrast, the repeated compression of tubing in peristaltic pumps (image below) can cause them to degrade with time, necessitating regular replacement and increasing maintenance requirements.

Image Credit: Fluid Metering, Inc.

Conclusion

While both Fluid Metering valveless piston pumps and peristaltic pumps have their uses in fluid handling, the benefits of piston pumps make them the better choice for many demanding applications.

For more than 60 years, Fluid Metering engineers have designed and manufactured dependable, high-precision pumps. Their precision, high-pressure capabilities, durability, versatility, efficiency, and low maintenance requirements make them the ideal solution for industries that require dependable and consistent fluid delivery.

About Fluid Metering, Inc.

Fluid Metering, Inc. (FMI) is a worldwide leader in life science pumps and dispensers, having pioneered the first valve-less piston pump over 64 years ago. With specialized expertise in fluidics and applications, Fluid Metering, Inc. supports instrument developers in tackling complex fluidic challenges.

Committed to innovation through collaboration, Fluid Metering, Inc. advances health, sustainability, and quality of life. ISO 9001:2015 certified.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.