What is Pulsation?

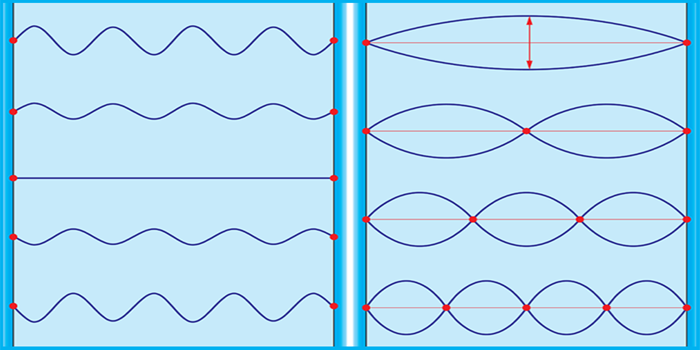

Pulsation is described as regular variations in flow rate within a fluidic system. It can be visually represented as the variation between peaks and valleys relative to a standard flow. In microfluidic pump configurations, pulsation may occur due to a range of design and operational elements. Such fluctuations in flow rate can greatly impact the stability and precision of microfluidic operations.

Image Credit: Fluid Metering, Inc.

Causes of Pulsation

Pulsation can originate from several sources within a system. While these individual factors may sometimes offset one another, they can also combine to increase overall pulsation.

- Mechanical action: The mechanical functions of certain pumps, such as peristaltic pumps, involve cyclic compression and relaxation of tubing, naturally introducing pulsation.

- Pressure fluctuations: In pressure-driven systems, changes in the applied pressure can lead to pulsatile flow, particularly if the pressure source lacks stability.

- Pump head and drive mechanism: The pump head influences the level of pulsation. For example, the flow profile of the FENYX Variable Dispense Pump is closely related to the pump head and is minimally affected by the drive mechanism.

- System configuration: Complex tubing arrangements with bends, restrictions, and diameter variations can enhance pulsations.

Impacts of Pulsation

Controlled pulsation provides various advantages for the following processes:

- Enhanced mixing: Pulsatile flows facilitate better mixing by creating fluctuations in velocity and shear stress over time, resulting in a more homogeneous mixture.

- Droplet formation: The oscillatory characteristics of pulsatile flows assist in the precise generation of droplets, which is crucial for processes like emulsification and encapsulation.

- Clog prevention: By periodically adjusting the flow dynamics, pulsatile flows can help reduce the risk of clogging in microchannels, dislodging particles that may lead to blockages.

- Improved cell cultures: In biological applications, pulsatile flows can simulate natural physiological conditions, encouraging the growth and survival of mechanosensitive cells, which is advantageous in tissue engineering bioreactors.

- Particle manipulation: The time-dependent nature of pulsatile flows enables precise particle manipulation, supporting processes such as cell sorting and filtration.

- Bioassay automation: Pulsatile flows provide consistent and repeatable conditions, improving the automation and reliability of bioassays.

Unchecked pulsation can result in significant problems, including:

- Flow instability: Variations in flow rate can create instability in processes that necessitate a consistent flow, such as continuous cell sorting or chemical reactions.

- Measurement inaccuracies: In analytical applications, pulsation can introduce noise and measurement inaccuracies, compromising the reliability of results.

- Decreased system lifespan: Unaccounted vibrations or stresses can shorten the system's lifespan, which is partially calculated based on expected wear.

Let's look at particle counting to emphasize the significance of reducing pulsation for precise measurements.

The primary objective of this process is to direct media through a defined area and monitor what moves through. The more the media continuously bounces back and forth within the area, the more challenging it becomes to determine whether each particle has successfully passed through.

Strategies to Mitigate Pulsation

To limit the adverse effects of pulsation, various system-dependent strategies can be used:

- Dual pump systems: Using two pumps that operate out of phase can effectively cancel out pulsations, resulting in a more stable flow. This can be achieved with either two distinct pumps or Fluid Metering’s Duplex Pump.

- Optimized pump design: Simpler systems with fewer moving parts, such as our CeramPump® valveless technology, help reduce pulsation.

- Tubing: Using longer, more flexible tubing can help decrease pulsations. The length of the tubing can be gradually increased until the desired flow characteristics are achieved.

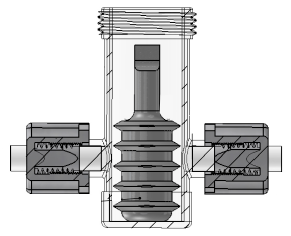

- External dampeners: Pulse dampeners can significantly reduce pulsation. Fluid Metering’s Pulse Dampener, featuring a bellows-shaped structure, lowers pulsation levels to below 10 %.

Fluid Metering’s Pulse Dampener. Image Credit: Fluid Metering, Inc.

- Varying motor speed: Adjusting the speed of the motor can result in a smoother flow for short dispense periods, a technique known as “Fluid Metering Smooth Flow.”

- Combining methods: By combining the techniques mentioned previously, pulsation-induced flow deviation can be reduced to below 1 %.

Understanding and controlling pulsation in microfluidic pumps is essential for maximizing the efficiency and accuracy of microfluidic systems.

About Fluid Metering, Inc.

Fluid Metering, Inc. (FMI) is a worldwide leader in life science pumps and dispensers, having pioneered the first valve-less piston pump over 64 years ago. With specialized expertise in fluidics and applications, Fluid Metering, Inc. supports instrument developers in tackling complex fluidic challenges.

Committed to innovation through collaboration, Fluid Metering, Inc. advances health, sustainability, and quality of life. ISO 9001:2015 certified.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.