As an engineer, the ability to dispense fluids through a non-contact tip in medical diagnostic and other devices could be transformative and potentially life-saving.

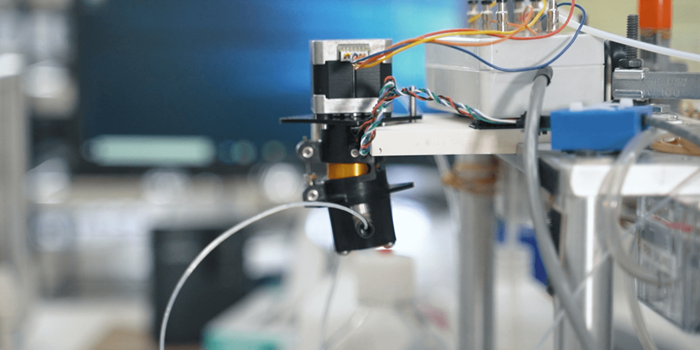

Image Credit:Fluid Metering, Inc.

Current dispensing methods primarily require contact, typically involving a submerged tip or a touch-off technique. These approaches are less than ideal due to risks of cross-contamination, non-repeatability, and inaccuracies. An optimal solution would involve a pump with non-contact dispensing capabilities.

Historically, options for dispensing small volumes of fluid (typically less than 10 microliters) have been limited to the aforementioned methods. Users may be seeking a more effective pumping solution that facilitates accurate and sterile fluid dispensing.

Fluid Metering's Solution to Non-Contact Dispensing

Fluid Metering's patented non-contact dispensing methodology enables precise and accurate dispensing of small fluid volumes while suspending the tip above the surface. This technique ensures that the fluid detaches cleanly, consistently, and at the targeted location.

This innovation is particularly advantageous for medical devices, such as diagnostics that require precise fluid dispensing to initiate reactions. The non-contact dispensing method enables highly accurate placement, facilitating interaction with the intended medium while providing the necessary delicacy for such applications.

Furthermore, this non-contact dispensing methodology can be applied to various medical devices. Fluid Metering has developed this methodology to achieve non-contact dispensing outcomes and is prepared to collaborate with you to integrate it into your equipment.

Implementation of Non-Contact Dispensing

There are four main areas to address when implementing non-contact dispensing into a device.

Firstly, one must assess the type of tip to be used, ideally a hydrophobic tip that minimizes fluid attraction. Next, the tip materials must be compatible with the fluid being dispensed.

The gauge size of the tip is also critical; if it is too large, fluid may not detach cleanly, leading to volume variability. Conversely, if it is too small, the fluid may jet out forcefully and cause splashing. An appropriate tip diameter is essential for repeatable dispensing while reducing splash risks.

Tubing

The internal diameter and material of the tubing connecting the pump to the dispense tip are crucial. Any air in the line can act as a cushion, affecting fluid dispensing accuracy.

Ideally, the tubing should be hydrophobic with a rigid wall. Flexible tubing may expand under pressure, causing pressure fluctuations and inaccurate dispensing. A smaller internal diameter is generally preferred.

Pump Motor

Evaluating the motor acceleration (the pump itself) is important; it must reach the desired speed swiftly to ensure consistent volume delivery.

Deceleration is equally critical; the pump must halt as quickly as it starts to maintain precision in dispensing.

How the Pump Head is Primed

The presence of air in the pump head can disrupt the entire system, making it nearly impossible to dispense small volumes accurately.

Priming is essential from the initial startup of the pump to eliminate any air in the tubing. Excess air can compromise both the accuracy and precision of the pump and hinder the effectiveness of the non-contact tip methodology.

How Fluid Metering Can Assist You

Fluid Metering believes that users should not have to compromise on quality. This conviction led to the development of a non-contact dispensing methodology designed for volumes of less than 10 microliters of fluid.

Fluid Metering’s team of experts supports users throughout their journey, helping them select the appropriate pump and tip for their specific requirements. Their team can assist in the following ways:

- Consult with Fluid Metering’s Business Development Experts: Experts guide users through the initial stages, ensuring collaboration with engineers who specialize in the user's unique needs.

- Direct Access to the Engineering Team: Users have a direct line of communication with the engineering team who work closely to develop a product tailored to specific specifications.

- Comprehensive Fluidic Solutions: The outcome is a complete fluidic solution that enables non-contact dispensing for your medical diagnostic device or other applications. Fluid Metering is dedicated to testing for reliability to ensure that pumps perform optimally and deliver the expected dispense volume.

Fluid Metering recommends the patented FENYX Variable Dispense Pump (formerly FVD) for non-contact dispensing applications.

Acknowledgments

Produced from material originally authored by Richard Hill from Fluid Metering.

About Fluid Metering, Inc.

Fluid Metering, Inc. (FMI) is a worldwide leader in life science pumps and dispensers, having pioneered the first valve-less piston pump over 66 years ago. With specialized expertise in fluidics and applications, Fluid Metering, Inc. supports instrument developers in tackling complex fluidic challenges.

Committed to innovation through collaboration, Fluid Metering, Inc. advances health, sustainability, and quality of life. ISO 9001:2015 certified.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.