Injecting new levels of 3D printed realism into the dental industry, the new Stratasys J720 Dental creates faster turnaround times so dental labs can streamline operations, fulfill more cases and grow new business without further capital expense.

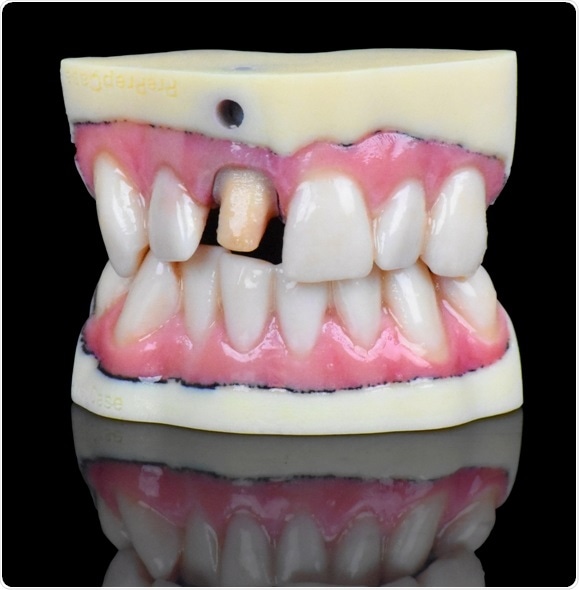

The new Stratasys J720 Dental 3D Printer sets new standards in realism for digital dentistry – leveraging more than 500,000 color combinations

Backed by more than 500,000 color combinations, the multi-material 3D printer produces extremely high resolution, patient-specific models with precise accuracy – at 1.75x the daily throughput of high-end DLP and SLA dental 3D printers

Labs today operate in a very competitive space where differentiation counts on mastering the digital workflow and expanding into new products and services. The J720 Dental 3D Printer is designed to change the game – allowing levels of speed, productivity and realism the market has never seen. This powers laboratories to meet the demands of a competitive market and push the boundaries of digital dentistry.”

Barry Diener, Dental Segment Sales Leader, Stratasys

With capacity to outperform top-of-the-line DLP and SLA dental 3D printers, the J720 can deliver 1.75x the throughput of competitive solutions while supporting quick turnaround of urgent cases.

A large build tray can print six materials simultaneously – increasing case volume and managing a full range of applications in a single print job. Reducing high-touch labor associated with management of small print bed single-material printers, the solution is able to accommodate a range of applications at one time.

Combining multi-materials and full-color realism, the J720 has the potential to increase patient acceptance of case presentations – offering realistic treatment models before work ever begins. Offering faster time-to-part, the 3D printer also achieves the highest-resolution 3D prints for models.

Backed by the award winning GrabCAD Print software, the J720 guarantees a simplified, all-digital workflow – making it easy to transition from CAD model to 3D printed part. The software’s workflow streamlines job management in large labs utilizing multiple systems.

Cloud connectivity makes it easier for technicians to conduct remote monitoring – keeping track of multiple printers from a single source and automatically tracking material consumption and machine utilization. Enabling labs to save both time and money, the solution virtually eliminates requirements for high-touch, manual intervention.