This year’s COMPAMED (Düsseldorf, 18-21 November) will see 3D printing leader, Stratasys, presenting the latest developments in 3D printing for a range of applications to enhance the design and development of medical devices on its booth (Hall 8b, Stand N02). Visitors to the booth will also be able to learn about the newly-launched J750™ Digital Anatomy™ 3D Printer, which offers medical institutions the unique ability to produce 3D anatomical models that replicate the feel of human tissue – eradicating the need for cadavers and enabling them to accelerate medical device testing and validation.

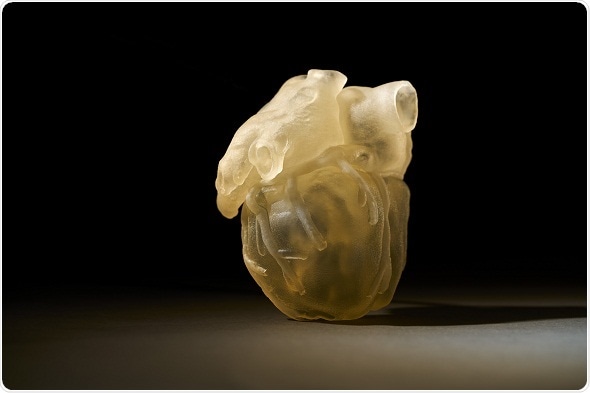

3D printed heart model produced on the new J750 Digital Anatomy 3D Printer that mimics human tissue in feel, responsiveness, and biomechanics

Designed to replicate the feel, responsiveness, and biomechanics of human anatomy via life-like 3D models, the system improves surgical preparedness and training, while helping bring new medical devices to market faster. Already being utilized by several leading medical institutions, including US-based, The Jacobs Institute, the Digital Anatomy 3D Printer enables medical practitioners to focus on specific pathologies and recreate actual tissue response, eliminating the need for cadavers, animal, traditional and virtual reality models. At a COMPAMED, a series of 3D printed heart models mimicking human tissue will be featured for the first time ever at a tradeshow.

The company will also provide a live demonstration of its latest FDM 3D printing technology, enabling medical device manufacturers to significantly accelerate the design and development of new devices, while reducing cost throughout the development process. The Stratasys F370 3D Printer will running live on the stand, which allows medical device manufacturers to rapidly produce fully-functional prototypes that precisely replicate the final product. This enables a comprehensive evaluation of the fit, form and function of new devices before investing in expensive clinical trials and moving to final production.

Lastly, via a series of real-life case studies, visitors will be able to learn how the use of patient-specific 3D printed models pre-surgery is enabling hospitals to improve patient care, while also increasing time and cost efficiencies. One example is the Department of Urology and Kidney Transplantation at the Bordeaux University Hospital (CHU) in France, whose surgical team is utilizing Stratasys PolyJet3D printing to improve kidney cancer surgery. Using ultra-realistic 3D printed models comprising the patient’s kidney tumor, main arteries and vessels – each in a different color – is helping the CHU to perform precise and successful kidney-sparing surgery and improve patient outcomes.

Insightful presentations throughout the show

On the first day of COMPAMED(Monday 18th November 12:30 pm, Hall 8a, 1. Booth G40 | Forum Area)Arnaud Toutain, Stratasys Healthcare Sales and Development Manager EMEA, will deliver an insightful presentation entitled ‘Bringing Medical Models to Life with 3D Printing’, exploring the benefits of 3D printing for the healthcare industry. In particular, the transformational role 3D printed anatomical models pre-surgery is having on improving patient care and surgical outcomes.

Toutain will also give a presentation entitled ‘Additive Manufacturing for Medical Devices: A Versatile Tool to Support the Whole Product Lifecycle’ on the third day of the show (Wednesday 20th November 16:30, Hall 8a, 1. Booth G40 | Forum Area). The presentation will address how medical institutions around the world are leveraging advanced 3D printing across the entire value chain to optimize efficiencies.

Finally, on Thursday 21st November 14:00, Hall 8a, 1. Booth G40 | Forum Area, Daniel Princ, Sales Operations and Development Director EMEA, Stratasys, will explore how medical device design, development and production can be enhanced using 3D printing.

See Stratasys at COMPAMED on Stand N02, Hall 8b, at the Messe Düsseldorf, 18-21 November 2019.