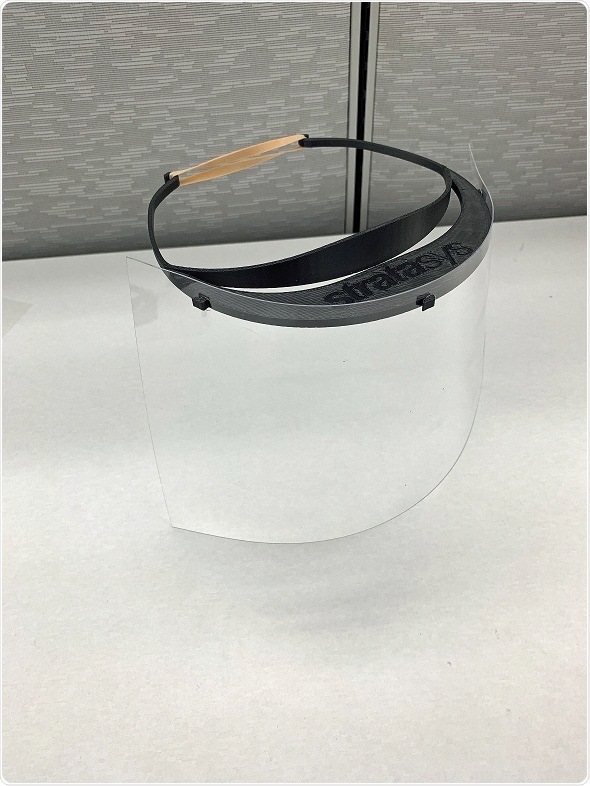

Stratasys Ltd. has announced a global mobilization of the company’s 3D printing resources and expertise to respond to the COVID-19 pandemic, spanning its Stratasys, GrabCAD, Stratasys Direct Manufacturing and partner network with donated printing capacity across all regions. The initial focus is on providing thousands of disposable face shields for use by medical personnel.

Stratasys and its partners are producing several thousand face shields with 3D-printed plastic frames

In the United States, Stratasys has set an initial goal of producing 5,000 face shields by Friday, March 27, at no cost to the recipients. This includes both a 3D-printed frame and a clear plastic shield that covers the entire face. The company will have the ability to scale to an even faster rate of production.

Any 3D printing shop that wishes to help print plastic frames, can fill out an online form to be invited to join the effort. The company is also posting the full face shield printing and assembly instructions by Monday, Mar. 23 on its COVID-19 response page.

One of the world’s top hospitals has told Stratasys they use 1,530 disposable face shields every week even without the surge created by COVID-19 and is down to six days’ inventory on hand, with the pandemic still building momentum.

Stratasys said medical technology leader Medtronic and Minneapolis-based Dunwoody College of Technology will provide support for the plastic shield material.

We are humbled by the opportunity to help. We see additive manufacturing as an essential part of the response to the COVID-19 global epidemic. The strengths of 3D printing – be anywhere, print virtually anything, adapt on the fly – make it a capability for helping address shortages of parts related to shields, masks, and ventilators, among other things. Our workforce and partners are prepared to work around the clock to meet the need for 3D printers, materials, including biocompatible materials, and 3D-printed parts.”

Yoav Zeif, Stratasys CEO

Stratasys has scores of professional 3D printers available to apply to the challenge of producing shields at scale, particularly across its Stratasys Direct Manufacturing facilities, which are based in Eden Prairie, Minn., in and around Austin, Texas, and Valencia, Calif. A number of other large manufacturers and educational institutions with production grade 3D printers have donated their capacity to help. These include Wentworth Institute of Technology in Boston, Queensborough Community College in New York City, and the Savannah College of Art and Design in Savannah, Ga.

Stratasys has set up a web page where organizations can request 3D printed products to help with the crisis, offer 3D printing capacity, or request 3D printers or material for medical- or safety-related purposes. Visit www.stratasys.com/covid-19.

The company is also planning to respond to the crisis in additional ways. An initiative led by anesthesiology residents of Massachusetts General Hospital called the CoVent-19 Challenge is planning to ask engineers and designers to help develop a new rapidly deployable ventilator and other innovative solutions to the ventilator shortage, and Stratasys plans to support the challenge and promote it via its GrabCAD community of more than 7 million professional designers, engineers, manufacturers and students.