Hosokawa Micron offers a range of novel technologies for use in primary and secondary pharmaceutical production of active pharmaceutical ingredients and intermediates to respiratory drugs, vitamins and food supplements. The technology and skills delivered by Hosokawa Micron range from lab and pilot plant through to full manufacture, offering straight forward and practical solutions to meet complex production requirements.

Hosokawa Micron is a leader in the design of containment solutions that ensure the safety of operators, products and the environment in the manufacture of highly potent drugs. The company offers a range of custom engineering solutions, including the unique re-design of standard Hosokawa Micron milling, filling and weighing and other equipment. By integrating these solutions into high containment isolators and booths, customers can achieve optimum operational efficiencies.

Pharmaceutical Isolators 10ng

With the isolator systems offered by Hosokawa Micron, customers can handle products down to operator exposure levels (OELs) as low as 10ng/m3 STEL. The handling of highly active or toxic chemicals requires such ultra-high containment levels in order to ensure product integrity and operator safety.

Hosokawa Micron offers isolator systems for both automated and manual processing and handling procedures, in the form of single units and multi-cell variants where individual processes are separated by defined barriers. These systems are ideally suited for key procedures such as milling, micronizing, drying, dispensing, and product pack off.

Re-Engineering of Equipment Integration

Hosokawa Micron has extensive experience in the integration of its own processing equipment as well as third-party systems within isolator systems. By re-engineering Hosokawa technology for integration within the isolators, the company can provide the most ergonomic work area.

Production Flexibility Improved by Interchangeable Equipment

Systems that incorporate interchangeable size reduction equipment are allowing customers to benefit from the flexibility advantages of end products of various sizes. The usability of isolators is further “future proofed,” by engineering for flexible/interchangeable feed options.

Ergonomic Design

The modification of early stage designs using the last 3-D modeling software and the production of wooden mock-ups, enables customers to achieve optimum equipment placement and ergonomic usability confirmation.

Downflow Booths 1µg

Using Hosokawa downflow booths provides a safe working environment for operators, offering protection from dangerous, harmful, toxic or sensitizing dusts produced while performing powder handling processes manually.

Examples of these processes include sampling, dispensing and charging and offloading sub-division from powders or solvents and drum loading and un-loading. The ergonomic design also allows integration of packing or processing equipment.

Hosokawa Micron can provide a variety of affordable and effective downflow booth solutions that can ensure operator safety, even at 1µg OELs, owing to its modular approach and a mixture of standard components and non-standard designs.

Modular Design

By using its unique modular design approach, Hosokawa Micron can now provide wider and deeper design booths that are capable of increasing the actual ‘protected work area,’ The widest downflow booth built by Hosokawa Micron so far measures 11m. By using modular construction methods, this can be extended further.

Green Booths

Hosokawa Micron also offers green booth design options such as improved air filtration, energy-efficient LED lighting, and high-efficiency, quieter fans, thereby enabling customers to save up to 30% on their operating costs.

Modeling and Simulation

The specifications of the equipment can be verified by customers prior to production using the latest modeling software tools. Powerful computational fluid dynamics simulation can be used to help enable the following:

- Prediction of 3D airflows

- Checking at design stage

- Assessment of the potential effects on containment and airflow patterns of placing objects, operators, and equipment in the downflow booth

All these are key factors in achieving critical OELs. This means engineers at Hosokawa Micron can achieve optimum placement of equipment and operations inside the booth, right at the initial stages of design.

Pack-Off Filling and Weighing Systems

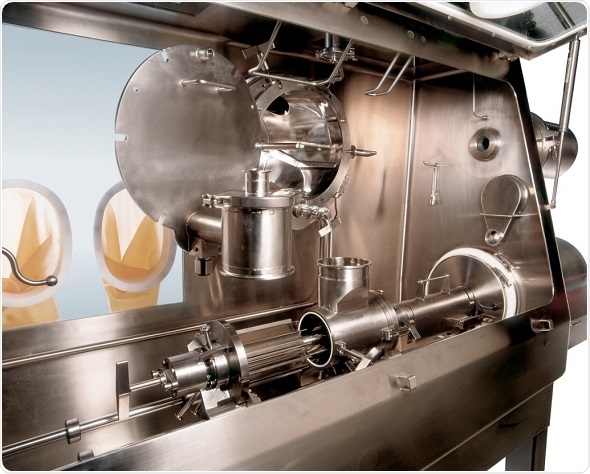

Hosokawa Micron offers a range of filling and weighing systems (Figures 1 and 2), which can serve either as standalone units or be integrated within isolators or downflow booths. These systems ensure continued security of products and operator safety in end of line activities.

The systems offer filling accuracies as low as ±10g and containment levels ranging from 1000µg/m3 down to nano levels. The flexible design enables a variety of containers to be handled.

Figure 1. Hosokawa Micron’s batch milling and pack off system

Figure 2. Hosokawa Micron’s filling and weighing system

Process Technologies for Tomorrow

By working closely with customers, engineers at Hosokawa Micron design the most suitable process and containment solutions that will meet customer needs. The company is recognized for its engineering excellence and design innovations and is a specialist in processing powders and particles and solving processing problems.

It offers a range of value-added solutions across a wide range of technologies including milling and micronizing, mixing, drying, classifying, screening, nanotechnology, agglomeration and compaction.

About Hosokawa Micron Corporation

Hosokawa Micron Corporation was established in 1916 as Hosokawa Iron Works in Osaka, Japan. Today, Hosokawa Micron Group is a world leader in providing process solutions in the fields of powder and particle processing technology, blown film technology, and confectionery technology.

Hosokawa Micron Group maintains facilities for research, engineering, manufacturing and service throughout Asia/Oceania, the Americas and Europe. Hosokawa Micron is advancing 100 years of powder and particle technology experience and market leadership in the future with the application, development and commercialization of ultra fine composite particles in the rapidly expanding field of Nano Particle Technology.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.