Introduction

Flexible application options are essential for optimal utilization of laboratory instruments in many laboratories. In those laboratories where more than one user is dependent on a single instrument, flexible operation can result in usage frequency.

Likewise, flexible operations can result in increasing the efficiency of laboratories having many different applications. This is particularly so for PCR, as this procedure takes a considerable amount of time in a total workflow. This article presents some potential flexible applications of the dual block thermocycler Mastercycler® nexus GX2:

- PCR optimization through temperature gradient function

- PCR performance comparability and reproducibility on the 32-well and 64-well blocks

- thermic independence of the 32-well and 64-well blocks

Materials and methods

Two PCR runs were performed on a Mastercycler® nexus GX2. A temperature gradient function, in horizontal orientation, for 8 positions within the 64-well block is presented to the user. In order to amplify a GC-rich fragment (484 bp) from the human β-actin gene (ACTB), two primers were employed: Primer 1: 5’-ATC GCC GCG CTC GTC GTC-3’ and Primer 2: 5’-TGG GTC ATC TTC TCG CGG TTG G-3’

To set up the PCRs, a PCR Nucleotide Mix (Promega) and the GoTaq® Hot Start Polymerase kit (Promega®) were utilized. The template chosen was the human genomic DNA (Roche®). A 20μL reaction contained the following components: 300nM per primer, 2.5mM Mg2+, 200μM dNTPs, 1 x GoTaq Flexi

Buffer, 2ng/μL template DNA, and 0.5U of the GoTaq Hot Start Polymerase. After agarose gel electrophoresis, DNA-binding fluorescent dye ethidium bromide was utilized for detecting the PCR products. The Agilent® DNA 1000 kit was employed to carry out additional quantification of the PCR products, as per manufacturer’s instructions on the Agilent 2100 Bioanalyzer®.

(1) PCR optimization using the temperature gradient function

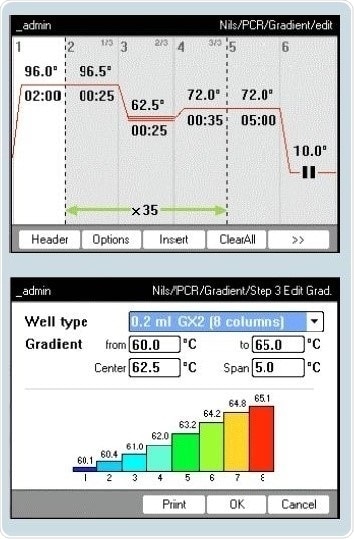

In order to determine an appropriate annealing temperature (Figure 1), a primary temperature gradient run was performed. Subsequently, another gradient run was performed for determining the optimum temperature for denaturation. For this purpose, a gradient in the range of 93-98°C for the denaturation process and the annealing temperature fixed at 64°C during the first PCR, were employed, with no change in other conditions.

Figure 1. PCR program of the temperature gradient run for determination of a suitable annealing temperature. A screenshot for gradient programming in the Mastercycler nexus GX2 software is shown below.

(2) Reproducibility and comparability

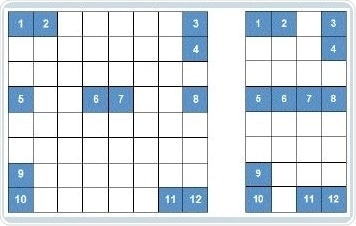

Three PCRs were run in parallel on the 32-well and the 64-well blocks, by utilizing the PCR system that was optimized under the step (1). To this end, each block was loaded with 12 samples, which were distributed across the block, as shown in Figure 2.

Figure 2. Positioning of the twelve PCR samples on the 64-well and the 32-well block, respectively.

(3) Thermic independence of both thermoblocks

For testing thermic independence, a PCR run with 12 samples was carried out on the 64-well block by utilizing the aforementioned conditions. On the 32-well block, a temperature of 4°C was continuously maintained. Another run with 12 samples was performed on the 32-well block during which a temperature of 99°C was maintained on the 64-well block.

Results and discussion

(1) PCR optimization via gradient function

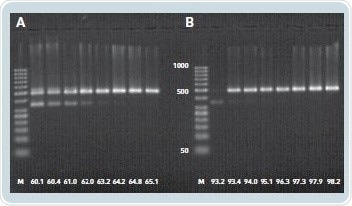

The Mastercycler nexus GX2 gradient function allows annealing temperature optimization and denaturation temperature optimization. It was evident from the examination of the PCR products arising out of the annealing temperature gradient run that small annealing temperatures caused non-precise products to be formed at approximately 350 bp and over 500 bp (Figure 3). An annealing temperature of 64°C was chosen for the subsequent runs.

Examination of the other gradient run showed that non-precise products were formed at a lower denaturation temperature of about 93°C (Figure 3). At temperatures more than this level, only the specific product connected with a larger yield was noticed. Therefore, the appropriate future denaturation temperature was found to be 97°C.

Figure 3. PCR products resulting from the gradient runs for determination of (A) annealing and (B) denaturation temperatures, respectively. The appropriate gradient temperatures [°C] of both runs are inserted at the bottom of the gel image (M: Length marker, GeneRuler™ 50 bp DNA Ladder, Thermo Fisher Scientific®).

(2) Reproducibility and comparability

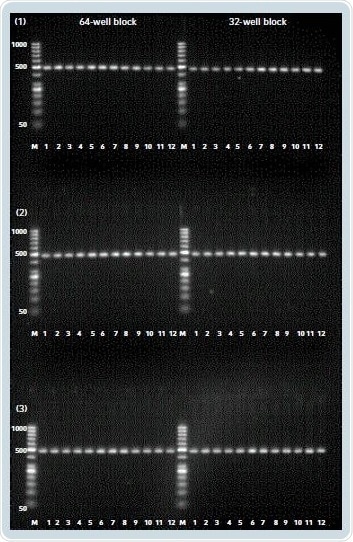

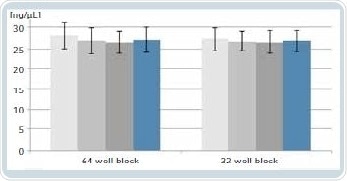

Three repeated PCR runs, where each PCR run had 12 samples, were utilized to test PCR result reproducibility procured from one block, and to compare the PCR products from the two well blocks (Figure 4a). Examination of the PCR product concentration, as measured on the 2100 Bioanalyzer using the Agilent DNA 1000 kit, reveals the reproducibility of the product yields on the 32-well and 64-well blocks (Figure 4b).

The average concentration of the PCR product was 26.82ng/μL with 2.5ng/μL as a standard deviation. Taking into account these results, the 36 specimens from the 32-well block illustrate comparable performance in all of the three runs. At a concentration of 27.14ng/μL and a standard deviation of 2.95ng/μL, similar results were obtained from the 64-well block also. These results show consistent result quality in a particular block as well as high consistency between the two blocks.

Figure 4a. Gel image of the PCR products resulting from the triplicate repeat PCR runs on the 64-well block and 32-well block.

Figure 4b. Arithmetic means +/- standard deviations of the PCR product concentration of the triplicate repeat PCR runs (light gray bar corresponds to (1) on the gel (fig. 4a), medium gray bar to (2) and dark gray bar to (3)) on the 32-well block and 64-well block. The blue bar displays the overall arithmetic mean +/- standard deviation of the respective block.

(3) Thermic independence of both thermoblocks

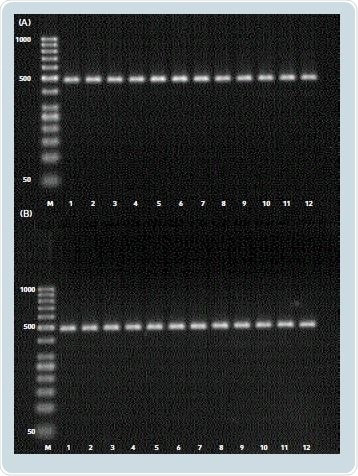

The two runs confirmed an equal, good PCR performance in all of the 12 positions (Figure 5). Obviously thermic influence was not exerted externally, even when the adjacent block was maintained at an extremely low or high temperature.

Figure 5. (A) Twelve PCR products of the 64-well block during a permanent holding temperature of 4°C on the 32-well block; (B) twelve PCR products of the 32-well block during a permanent holding temperature of 99°C on the 64-well block (M: Length marker, GeneRuler™ 50bp DNA Ladder, Thermo Fisher Scientific).

Conclusion

Besides the separate usability of the two thermoblocks, a user can utilize the new Mastercycler nexus X2 and its varying 32-well block and 64-well block formats, for testing different numbers of samples. Therefore, the Mastercycler nexus X2 offers maximum flexibility and provides high quality results. This combined performance emphasizes the utility of the instrument for laboratories, where more than one user is dependent on the thermocycler, and also for those laboratories carrying out various PCR reactions with low and medium number of samples. A variant, Mastercycler nexus GX2, extends the flexibility so as to provide a temperature gradient function to the user.

Acknowledgements

Produced from materials originally authored by Nils Gerke and Andrea Hellberg from Eppendorf AG, Hamburg, Germany.

About Eppendorf NA

Eppendorf NA, with headquarters in New York, are a subsidiary of Eppendorf AG (Hamburg, Germany) – manufacturer of laboratory instruments and consumables for the life sciences.

To make it easy for labs in the United States to benefit from Eppendorf quality, they provide total customer support and service: taking/tracking orders; product installation and training; application support; calibration services; general product maintenance and repair, and more!

Eppendorf's products

Eppendorf products are used in all types of life science research and testing settings – from basic laboratory applications to highly specialized cell and molecular biology applications. They are highly regarded for their quality design and performance – beginning with extensive research and development, adding state-of-the-art technology and ending with strict quality-controlled manufacturing are what make their products stand out from the rest. It is what has made them a brand you have been able to rely on for over 70 years.

Over the years Eppendorf has improved upon and added to their flagship products – pipettes and pipette tips, centrifuges and microcentrifuge tubes – to now include the most ergonomic liquid handling devices and automated pipetting stations, quiet centrifuges, fast and fully flexible thermal cyclers, sample-protecting deepwell plates, cell manipulation systems and microcapillaries, ultra-low temperature freezers, shakers, incubators and bioprocessing equipment.

Eppendorf's services

Customer Support Representatives are available M–F, 8:30 AM – 8:00 PM (EST).

Local Sales Representatives cover the entire US to give you the fastest best possible attention. They know their products – and better yet, they know your applications. Feel confident in their abilities to assess your needs and determine the best products and systems to give you the best results.

Field Specialists also cover the entire US to provide post-sales installation and training on their specialty systems and automation.

The Applications Hotline is manned by degreed scientists working in their own fully functional life science laboratory. They are on call and email-accessible to help you troubleshoot your application or answer any technical question you may have. The Eppendorf Services group provides a wide variety of support services such as pipette calibration, instrument maintenance programs, and expedited repair.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.