The role of a lab manager is one that comes with little downtime, as they act both as strategic managers and essentially as the tactical glue that keeps operations running. Thanks to the emergence of Smart Labs and Internet of Things (IoT) technologies, a range of novel tools have been developed to assist with their ever more complex responsibilities.

This article will investigate the options for lab managers to make full use of these technologies to support them in meeting their ongoing goals for development, as well as increasing their strategic impact on the overall organization.

Managing the Flow of Data

Handling the flow of data is a central duty in science, whether this refers to tracking, recording, analysis or storage.

As well as primary experimental data, the data sphere in the modern lab has grown to encompass inventory data, test protocols, employee training records, environmental data, instrument calibration records, and perhaps most exasperatingly, test results from various pieces of equipment that do not connect with one another.

As laboratory data is stored in multiple unconnected forms, the difficulties of managing data – from collection to storage to access – are myriad. These individual pockets of data include some records that are manually collected and logged in notebooks, complete with handwritten signatures, to other records that are entirely digital.

Finding one’s way around – and eventually linking – these disconnected pieces of data is one of the most significant challenges faced by organizations both large and small. The difficulties and the costs are at the same time apparent and opaque.

Where comprehensive access to lab data across the enterprise is not possible, the organization is not able to make use of the full value of the data. This access is made difficult by two serious issues:

- Gaps: Whether these are a result of either a lack of technology or resources, large data gaps are a frequent issue, either in the granularity of data collected, or an absence of other data altogether.

- Integration: Lab data is not always cohesively linked with traditional management information systems in ways that could offer value. This could include linking training information with HR records, associating the costs of experimental runs with finance reports, or making certain that proper information is stored in the ERP.

Significant changes are soon to be felt in these areas.

By lessening the barriers to data collection, the idea of the Smart Lab, filled with linked, data-collection systems ranging from smart instruments to intelligent sensors to analytics software, promises to deliver dramatic increases in the volume of lab-produced data.

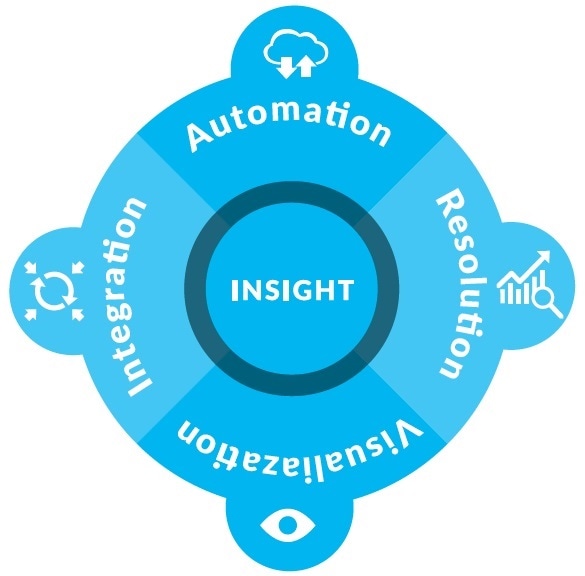

Figure 1 - Smart lab solutions deliver new insights, enabled by automated, high-resolution data, powerful data visualizations, and integration with other systems.

For lab managers who take an open view of how to make use of this new paradigm to enhance operations, a strategic change will take place in how they execute their roles.

These lab managers will produce the structure through which further operational efficiency can be achieved, they will make better informed and more meaningful judgments, and they will offer improved strategic value to their organizations.

Tapping the Power of the Smart Lab

The Internet of Things (IoT) has enabled cutting edge developments in sensors, networking and computing power to enhance our homes and workplaces as well as our general health and fitness, with innovations ranging from the Smart Building to the Smart Home to the Quantified Self movement.

The technologies which enabled these developments are now being introduced to the lab with the assertion that scientific studies can be improved and accelerated with the help of new data from new sources.

Smart Lab solutions share these abilities:

- Automated Data Gathering – Making sure that teams can access any and all data needed to complete their work to the highest level.

- High-resolution Data – When working with large data sets, tools which can effectively manage, integrate and analyze are essential. Additionally, they should be able to generate opportunities for improved analysis and more profound insights.

- Visualization – To rapidly provide visibility into large data sets.

- Integration – To make certain that all data can be shared between systems.

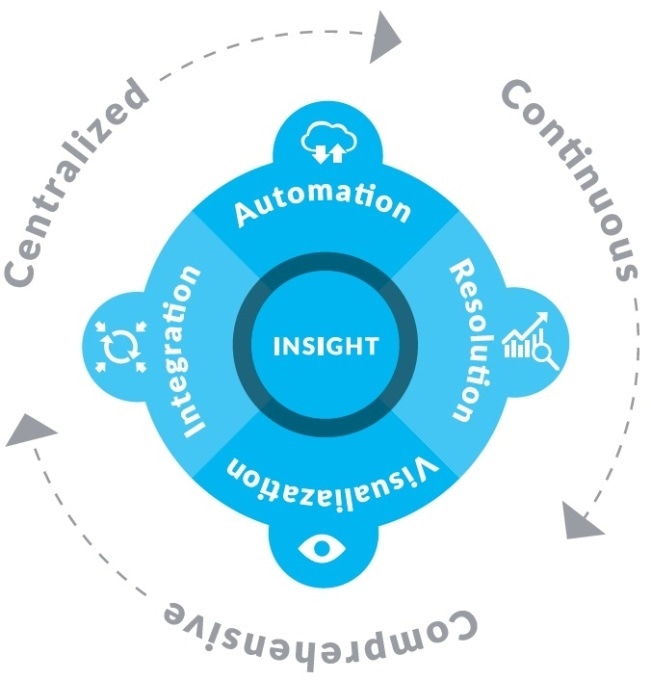

- Continuous – 24 hour surveillance of equipment, instrumentation, methods and environmental variables eradicates data gaps, and generates huge new data assets.

- Comprehensive – All equipment, environment, and methods can now be tracked and observed without gaps.

- Centralized – Data from a range of systems, equipment and workflows can be cohesively joined and cross referenced, streamlining analysis.

Smart systems which have been optimized for use in the lab ensure that:

- High value assets can be monitored and safeguarded with personalized alert triggers.

- Data from instruments can now be gathered automatically and delivered straight to the cloud for analysis, sharing and storage.

- Experimental data can be remotely monitored and more closely managed with immediate access from any location.

- More profound analysis is both enabled and made faster, as data from a variety of sources can be synthesized and examined for deeper insights into patterns and relationships.

- Repeatability is enhanced when experimental results can be monitored and logged, including both experimental methods and exact environmental conditions in the research setting. This also enables optimization of the scale-up process.

- Reports and documentation to support GLP and GMP accreditation are far simpler to collect and preserve.

- Data on use of consumables can be directly shared with purchasing systems, while incoming raw material data can be shared with manufacturing QA/QC teams.

- Environmental efficiency is enhanced, as actual data feedback can be used to optimize environments and conditions.

- Operational efficiency is improved through the analysis and optimization of usage and utilization patterns.

Strategic Long-Term Value

From a financial viewpoint, Smart Lab systems generally have fairly modest costs, with the largest portion of the expenditure being in organizational planning and consideration to determine how best to fully make use of the value brought in by the systems.

Instead of being thought of as overhead costs, required to guarantee R&D or Production quality, Smart Lab systems and the data they produce allow labs to confirm their positions as vital assets in the operational and strategic well-being of an organization.

Such systems have the capacity to drastically alter the way science is executed, but in order to do so, they need novel consideration from lab managers and the teams they support.

From Lab Manager to Data Strategist | Expanding the Lab Manager Role

Smart Lab systems offer the chance to enhance both operations and experimental science. To do so, they require the mind-set of both a traditional scientist and a data strategist.

Instead of managing the problems caused by equipment or experimental failures after an incident, Smart Lab solutions can be employed to predict possible failures, lessening downtime, as well as lessening the demand on labor for repetitive tasks, allowing teams to reorganize scant resources.

With the added benefit of new, in-depth data on process implementation, these systems can also offer information to allow users to make laboratory procedures more straightforward and essentially, streamline their science as a whole. The solution is to have both the data and the tools to apply it in new and significant ways.

One outcome of this flood of high-resolution data is a mounting burden of data-management. This increases the importance of creating strategies for acquisition, storage, tracking, access, integration and safeguarding.

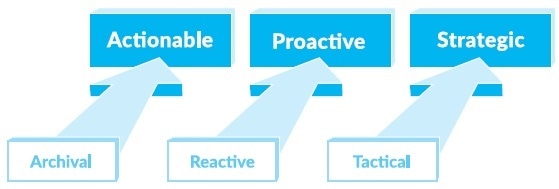

Lab managers are not just thinking about the systems and tools required, but are also developing data-management strategies that take into account the need to share crucial data with major stakeholders both in and out of the lab. Both the volume and value of this data are restructuring the understanding of laboratory data along a trio of trajectories:

From Archival to Actionable

One of the most significant offshoots of the introduction of the Smart Lab is that real-time data streams immediately convert data from an archival concern to an actionable asset. The revolution of real-time data allows teams to know immediately whether equipment is running within particular parameters or not, or if something needs an instant response.

These abilities act as insurance policies of a kind, assisting with the prevention of sample loss, and allowing teams to diarize preemptive maintenance to circumvent future problems as well.

The manner in which teams handle data and outcomes is entirely altered by the introduction of real-time data. Previously, test results from each stage of a workflow would just be archived for examination at a later date, frequently as a result of an issue that needed to be fixed.

By consistently tracking each stage of the procedure, as well as the existing conditions, it is possible to gather metadata on the physical environment as well as actionable insights. Some examples are:

- Tracking and logging temperature, humidity, air pressure and light in real time allowed a materials science research and development team working on a drug-delivery coating to gain insight that when the ambient humidity was above 56%, their process was unsuccessful, and that when it was below that threshold, it would succeed.

- Accessible data displaying comprehensive equipment performance allowed a team to rapidly assess the viability of diverse equipment for their GLP process, and opt for a cold room over a freezer due to smaller fluctuations in cold-room temperature.

- Visualizations of -80C freezer data over a month allowed a team to rapidly evaluate the condition of the equipment and plan maintenance.

Each of these instances illustrates the quantifiable impact of having actionable data, whether to increase efficiency or enhance repeatability.

From Reactive to Proactive

Thanks to Smart Labs, with data available at all times and locations, lab managers are at far less risk from occurrences that were previously outside their control. Some examples are:

- Instruments are now equipped with sensors attached that can measure usage levels, offering the lab manager data on the levels of testing carried out on any instrument. This enables them to predict levels of consumables, schedules and frequencies of cleaning and recalibration of instruments, and even to plan for instrument replacement.

- Intelligent sensor devices that constantly track temperature can be attached to lab equipment such as oven, freezers or incubators to notify selected users when a problem occurs.

Whether the issue is the result of a power outage, or simply a freezer door not properly closed, the ability to remotely monitor allows teams to address potentially serious situations before crucial samples or materials are irretrievably damaged.

Real-time visibility also allows lab managers to track the health of equipment over time, assisting them in detecting early warning signs of possible failure in aberrations from the usual data patterns.

- Wireless environmental sensors offer lab managers and staff insight into crucial variables including temperature, humidity, air pressure and light conditions. Awareness of these factors allows users to ensure that test results are being produced with consistently and are not being affected by variations in these areas.

- With the aid of web and mobile apps, it is possible to access Smart Lab data at any time. This allows lab managers to assess conditions either on-site or remotely, providing them with the data needed to determine whether a potentially serious situation (e.g. a power outage) requires them to attend the lab out of hours, or whether an incident can be addressed remotely.

From Strategic to Tactical

Thanks to novel data sources and the understanding it enables, lab data is becoming ever more strategic, allowing teams to make better-informed decisions as processes and products progress into other sections of the organization.

- Constantly monitored conditions, including ambient readings (temperature, humidity, pressure and light), equipment performance, instrument use, and availability of resources allow teams to make data-driven tactical decisions around operational procedures, investments in staff, technologies and produce versus purchase.

- QA/QC lab managers are no longer restricted to simply providing and accepting go/no go decisions based on test results. Instead, they can investigate for patterns of failures and endorse whatever alterations are required to alleviate/eliminate failures.

Additionally, they can access results remotely, and offer teams from several locations the capability to access results collaboratively.

- High-resolution data allows teams to utilize more refined machine learning and data analysis approaches to cross-reference numerous data sources and to gain more insight on the factors that may have an impact on lab-based work.

Smart Lab technologies give us better surveillance capabilities, enabling our team to be proactive about efficiency and continuous improvement initiatives.

Lyndsey York, Lab Manager, LabCentral.

This shared laboratory space, based in Cambridge, Massachusetts, was intended as a launch-pad for high-potential life-sciences and biotech startups, offering fully permitted laboratory and office space encompassing around 125 scientists and entrepreneurs.

Having access to both real-time and historical data helps shape decisions, and is helpful in fact-checking intuition about what may be going on.

Lyndsey York, Lab Manager, LabCentral.

With the assistance of a much fuller toolset, Lab Managers are positioned to become Lab Systems Managers, comparable to Finance Managers or Sales Operations Managers, employing novel technologies to better enhance processes and accepting more strategic roles within their organizations.

As is the case with all organizational shifts, these changes will not happen immediately, but just taking the initial steps in the right direction allows teams to be ideally placed for future success, positioning them well ahead of those who have not yet opened their eyes to these novel opportunities.

About Elemental Machines

Elemental Machines is helping scientists improve experimental reproducibility and accelerate scientific discovery.

From early research and discovery to manufacturing, everyone in biology and chemistry-based industries knows that the physical environment can affect the entire product lifecycle. What they don’t know is exactly how, or the cumulative cost of not knowing -- higher R&D expenses, slower time to market for innovative products and life-saving therapies, yield loss during manufacturing, and more.

With a deep understanding of these issues, Elemental Machines is delivering unprecedented insight into complex processes, helping customers refine and accelerate their work across all phases of product innovation.

By gathering and synthesizing environmental data into actionable information, Elemental Machines provides critical insights that improve transparency, repeatability and outcomes, and save customers time and money.

Track contextual variables (temperature, humidity, air pressure and light) in the research lab or monitor critical equipment performance (freezers, refrigerators, ovens, and incubators) for easy access to performance data, as well as alerts if readings are out of range.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.