For numerous industries and applications, the ability to monitor ambient environmental conditions, including temperature, pressure, humidity and light levels, is a crucial necessity. Variations in ambient conditions can have a negative impact on the equipment held in life science labs, which is often worth millions of dollars.

The processes frequently run by materials and chemical processing plants are also vulnerable to environmental conditions. Variations in humidity or pressure may result in negative impacts on quality and yield.

To ensure ideal growth conditions are upheld, incubators used for culturing medical, bio and pharma must also be continuously monitored.

Introduction

Whatever the particular quality standards or codes of compliance relevant to your industry, an effective environmental monitoring program should be able to answer these key questions:

- Do my environmental monitoring devices offer a high level of accuracy?

- Are we paying close attention to our environment – monitoring at regular points and taking action where conditions beyond standard thresholds are detected?

- Are the records we keep adequate to guarantee our product’s quality and safety?

- If our industry is regulated, are we keeping adequate records to be compliant with regulatory requirements?

In fundamental terms, there are five options for monitoring ambient conditions:

- Manual thermometers, barometers, hygrometers and light meters.

- Chart recorders to record one or more parameter

- Data Loggers

- HVAC facility monitoring, sometimes know as Building Management Systems

- Wireless IoT devices

This article will provide a short outline of each method, a description of how it is typically used and what the benefits and drawbacks of each method are.

Thermometers, Barometers, Hygrometers, Light Meters

These stand-alone instruments have been utilized for decades and are the simplest technique through which to monitor ambient conditions. Usually, a technician or other team member attends to each monitoring station a minimum of two times per day and logs the readings from each of the devices monitoring the environments.

The readings are noted in a logbook by hand and can be stored for record keeping. Although the task of taking and recording the measurements for temperature, humidity, pressure or light level is a simple one, other drawbacks can make this technique a less suitable option.

While the upfront outlay for such simple instruments is low, it is important not to forget the personnel costs of paying employees to measure and record this information on a daily basis. If a number of different environments are being monitored, this task could take up several hours each day, which could add up to a high cost of operation.

Furthermore, while storing log sheets for record keeping is entirely feasible, this method is the most vulnerable to human error. The reliability of data logged can be affected by factors as simple as whether the instruments are positioned in a manner that allows for easy reading, or whether the lighting in each area is adequate to view the instruments clearly.

Finally, manual recordings have lower levels of reliability than other types, as they could easily be tampered with in the instance of a regulatory or liability action.

Pros

The advantages of these simple, stand-alone instruments are their low capital costs, their ease of use and their well-established history.

Cons

The drawbacks of these methods are the high labor costs, the burdensome record keeping and the risk of human error. It should also be noted that this method does not allow for continuous monitoring, nor can it raise alarms in real-time should a problem occur.

Chart Recorders

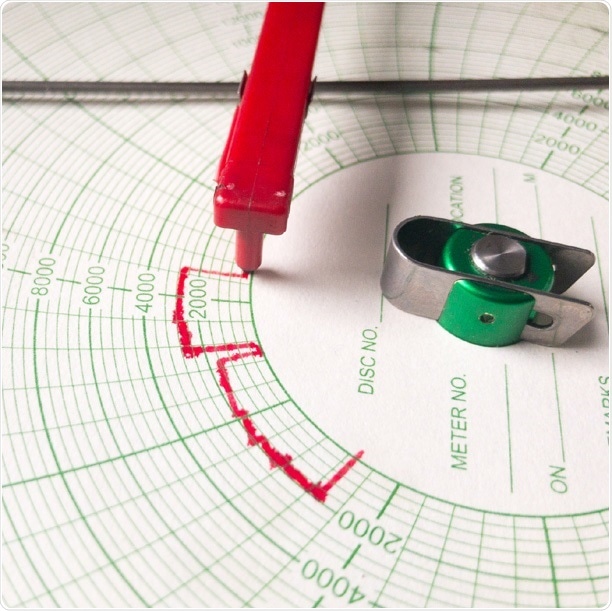

For the continuous recording of numerous readings, including temperature, pressure and humidity, chart recorders are a reliable, relatively low-cost and simple to manage method that has been employed for decades.

It is possible to save and file the charts to create a thorough record of ambient conditions. With these advantages, chart recorders have become a common method for monitoring a variety of environmental factors.

However, despite their reliability and simplicity, chart recorders still create a need for a member of staff to change the chart paper, typically once a day or once a week, and to store the chart safely for compliance. For greater resolution in readings, a larger chart recorder will be required.

A further factor for consideration is the cost of operation. Both charts and pens need to be replaced regularly, and if dozens of these are in use, the expenditure on paper charts and pens can start to pile up. Storage of the used charts can also become an issue as they are accumulated over time.

Pros

The advantages of chart records are that they are simple to use, require an uncomplicated form of data storage, and can offer continuous monitoring.

Cons

The downsides of this method are that it can incur relatively high operating costs over time, and the method of record keeping is cumbersome. The data has poor granularity and there is no capacity for real-time alarms or notifications in the event of an issue.

Data Loggers

Data loggers are instruments that measure and save readings electronically, offering continuous monitoring of a number of parameters. Some data loggers can measure several parameters simultaneously, including temperature, pressure and humidity. Data loggers can be set up to alarm when readings are out of specification.

Data loggers can be more expensive than manual instruments, but they offer the advantages of continuous monitoring and storage of data. They can also be set up to alarm for out of range conditions. The data saved by a data logger can typically be downloaded and stored using a USB memory device, or they can be connected to a local area network.

Data loggers store a lot of information that can be easily saved and retrieved for regulatory compliance. What data loggers typically aren’t set up to do is to alarm users remotely for out of spec conditions. They also are typically not set up to make data available in the cloud for easy access.

PROS • Continuous monitoring • Data storage is straightforward • Relatively simple

CONS • No remote alarming and notification • Data typically not available in the cloud

HVAC Facility Monitoring

There are a number of options for monitoring and control available when using more recent HVAC systems. These systems are frequently employed to identify issues with the HVAC system itself, such as chillers that are at risk of failure if not adequately maintained.

These systems can also be employed for other tasks, including monitoring and controlling particular environments within a building. Additionally, these systems can measure and track ambient conditions, including temperature, humidity and light levels, in crucial areas, such as food or vaccine storage.

With the use of HVAC facility monitoring systems, it is often possible to remotely monitor and control conditions which fall outside of specifications using cloud-based interfaces.

These systems are usually expensive and may only be useful for newly constructed environments. A further concern for the researcher or lab manager is that the alarm system is typically built to link to the facilities department and not to those running the laboratory or leading research.

Rather than alerting a lab manager, an alert notifying that the temperature is out of spec is most likely to be sent to a facilities manager. As they may be unaware of the importance of the work being undertaken in the monitored environment, they may not act with the necessary urgency.

Pros

The advantages of HVAC facility monitoring are that it offers continuous monitoring, cloud-based data storage and has the capacity to set off an alarm for out of spec conditions.

Cons

The downsides of this method are that it can be very costly, may only be practical for newly built environments, and the alarm system may not be connected to the appropriate team.

Wireless IoT Monitoring and Alarming

With no wires or connections required, wireless IoT monitoring is simple to set up. Each element runs on battery power and can connect directly to the internet, and to a bespoke data portal in the cloud. With the portal, the user can monitor equipment in real-time as well as receiving immediate email or SMS alerts for out of spec temperatures.

This method circumvents the risk of human error, can store data for lengthy periods, continuously monitors equipment and immediately alerts users when out of spec conditions are detected.

Data is stored securely in the cloud and is simple to access for regulatory requirements. Where battery power is low or connectivity issues occur, users receive alerts, ensuring no data is lost.

Pros

The advantages of wireless IoT monitoring are that it is simple to install, offers continuous monitoring with cloud storage of data and that it offers alerts for out of spec conditions.

Cons

The downside of the method is that initial setup costs are slightly higher than with other methods.

Regulatory Compliance

There are a large number of quality and regulatory standards across a variety of industries which require monitoring of environmental conditions, secure data storage and alerts for out of spec conditions. Some of these standards include:

- FDA 21 CFR Part 11 compliance for electronic records to help guarantee that electronic data collected is accurate, reliable, and equal to paper records

- The Food Safety Modernization Act (FSMA) demands that proper temperatures of food are preserved all the way through the supply chain.

- The Joint Commission on Accreditation of Healthcare Organizations (JCAHO) states that rooms that are deemed critical, such as those where invasive procedures are carried out or where sterile items are stored, are to be in continuous compliance when being used for their intended purpose.

- The World Health Organization (WHO) Technical Report Series No. 961, 2011, Annex 9 offers guidance for the storage and transport of time- and temperature-sensitive pharmaceutical products, which necessitates monitoring and alarming for temperature and humidity.

About Elemental Machines

Elemental Machines is helping scientists improve experimental reproducibility and accelerate scientific discovery.

From early research and discovery to manufacturing, everyone in biology and chemistry-based industries knows that the physical environment can affect the entire product lifecycle. What they don’t know is exactly how, or the cumulative cost of not knowing -- higher R&D expenses, slower time to market for innovative products and life-saving therapies, yield loss during manufacturing, and more.

With a deep understanding of these issues, Elemental Machines is delivering unprecedented insight into complex processes, helping customers refine and accelerate their work across all phases of product innovation.

By gathering and synthesizing environmental data into actionable information, Elemental Machines provides critical insights that improve transparency, repeatability and outcomes, and save customers time and money.

Track contextual variables (temperature, humidity, air pressure and light) in the research lab or monitor critical equipment performance (freezers, refrigerators, ovens, and incubators) for easy access to performance data, as well as alerts if readings are out of range.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.