Sponsored Content by MerckReviewed by Emily MageeJan 22 2024

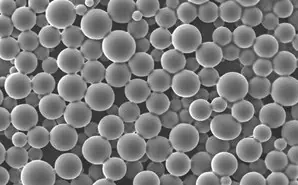

Microspheres and nanoparticles composed of biodegradable polymers like PLGA, polylactic acid and polycaprolactone find extensive use in drug delivery applications.

Image Credit: VonaUA/Shutterstock.com

Image Credit: VonaUA/Shutterstock.com

Active pharmaceutical ingredients (APIs), including both small molecules and biologic compounds, are often encapsulated in microspheres and nanoparticles. This encapsulation is utilized for specific drug delivery applications such as sustained release, targeted drug delivery, and protection of the API from premature degradation.

There are numerous drug-loaded PLGA microsphere formulations on the market. For instance, Lupron Depot®, which contains leuprolide acetate enclosed in PLGA microspheres, is used to treat prostate cancer and endometriosis. It is administered subcutaneously at intervals of 1 month, 3 months, or 4 months.

Upon administration of drug-loaded PLGA microspheres, the PLGA polymer undergoes in vivo degradation through hydrolysis of the ester backbone into non-toxic byproducts. As the PLGA degrades, the drug molecules are gradually released from the microspheres.

The rate of drug release can be adjusted by selecting the type of PLGA polymer and modifying the encapsulation process. For instance, the following parameters can tune the drug release profile:

- The ratio of lactide to glycolide (L/G ratio) in the PLGA polymers, e.g., PLGA with an L/G ratio of 50:50 has the fastest drug release.

- The molecular weight or inherent viscosity of the PLGA polymer, where higher molecular weight provides slower drug release.

- The terminal group of the PLGA polymer, where carboxyl-terminated PLGA polymers offer faster drug release compared to ester-terminated PLGA.

Degradex® PLGA particles

Degradex® PLGA microspheres and nanoparticles are polymeric particles ranging in size from nanometers to microns. Both plain and fluorescently dyed particles are available.

Plain PLGA microspheres and nanoparticles serve as control agents in drug delivery research and formulation or can be utilized to assess system compatibility before incorporating an API into the carrier.

Fluorescent nanoparticles and microspheres find applications in imaging and diagnostics, detecting binding events or enhancing signals. Moreover, fluorescent particles are valuable for fluid tracing, cell tracking, phagocytosis studies, fluorescence microscopy, and drug discovery research.

Figure 1. Image of API-loaded PLGA microspheres. Image Credit: Merck

Degradex® PLGA particles for surface conjugation

Degradex® PLGA particles can serve as carriers for drug molecules by allowing attachment to their surface. These particles, both plain and fluorescent, have surfaces functionalized with carboxyl groups. This feature enables the covalent attachment of various biological entities such as proteins, peptides, antibodies, antigens, and small molecules.

Utilizing Degradex® particles for drug conjugation can offer several benefits in drug delivery applications:

- Targeting specific sites, such as tumors1,2

- Facilitating cell entry3

- Aiding in crossing the blood-brain barrier4

- Enhancing solubility and bioavailability5

- Prolonging plasma circulation time, often achieved through the use of PEGylated PLGA nanoparticles6

Table 1. Degradex® PLGA Microspheres. Source: Merck

| Product Number |

Polymer |

L/D Ratio |

Inherent Viscosity |

Avg. Diameter (µm) |

| 805092 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

0.1 ±0 .02 |

| 805106 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

0.2 ± 0.03 |

| 805149 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

0.5 ± 0.1 |

| 805130 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

2 ± 0.3 |

| 805114 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

25 ± 3 |

| 805122 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

50 ± 5 |

Table 2. Degradex® Fluorescent Green PLGA Microspheres. Source: Merck

Product

Number |

Polymer |

L/D Ratio |

Inherent

Viscosity |

Fluorescence |

Excitation/Avg. |

| |

|

|

|

|

Emission (nm) |

Diameter (µm) |

| 805157 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

0.1 ±0 .02 |

| 805211 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

0.2 ± 0.03 |

| 805300 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

0.5 ± 0.1 |

| 805181 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

2 ± 0.3 |

| 805173 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

25 ± 3 |

| 805165 |

poly(D,L-lactide-co-glycolide) |

50/50 |

≈0.45 dL/g |

Green |

460/500 |

50 ± 5 |

Handling and use of Degradex® PLGA particles

1. Reconstitution

Degradex® microspheres typically come as lyophilized powder. Common applications often require reconstituting the particles in an aqueous medium like DI water or a buffer.

It is crucial to ensure that the particles are thoroughly suspended as individual particles without any aggregation before use. Follow the recommended protocol for resuspending Degradex® particles:

- Remove the product container from the freezer and allow it to warm to ambient temperature.

- Add DI water or buffer to the container.

- Gently mix the container's contents to ensure proper particle suspension; vortex and/or sonicate if needed.

2. Particle size measurement

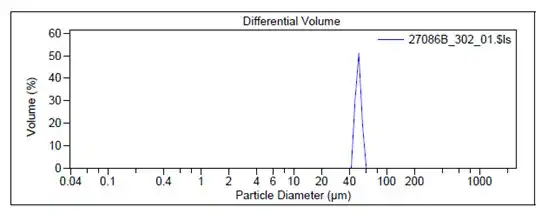

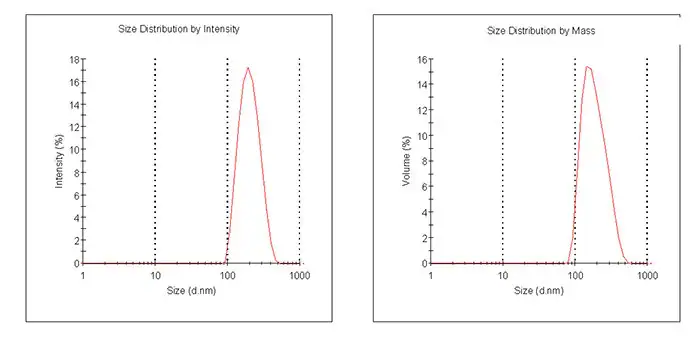

The particle size and distribution of Degradex® PLGA particles can be determined using several analytical techniques. These include laser diffraction analysis, sedimentation, elutriation, microscope counting, Coulter counter, dynamic light scattering, and imaging particle analysis.

Laser diffraction and Coulter counter are commonly used for microsphere size measurement, while dynamic light scattering is the preferred method for nanoparticles.

For instance, Figure 2 illustrates the particle size graph of a typical lot of Prod. 805122 using a Laser Diffraction Particle Size Analyzer. The particle size of Prod. 805211 is measured using a Dynamic Light Scattering instrument, with an example graph shown in Figure 3.

Figure 2. Particle size graphs measured by Laser Diffraction for Prod. 805122. Image Credit: Merck

Figure 3. Particle size graphs measured by Dynamic Light Scattering for Prod. 805211. Image Credit: Merck

3. Surface conjugation

Degradex® PLGA particles feature surface carboxyl groups, facilitating their interaction with amino groups on biological compounds to establish covalent bonds.

The subsequent conjugation protocol provides a general framework for conjugating biomolecules to Degradex® PLGA particles. Optimization may be necessary to achieve the desired reactivity and stability.

- Weigh approximately 10 mg of carboxylated particles into a 1.5-2 mL polypropylene microcentrifuge tube. Introduce 0.2 mL of 50mM MES buffer (pH 5.2) and vortex to suspend microspheres. If needed, sonicate.

- Create a 200 mg/mL EDC solution by dissolving 10 mg EDC (Prod. E1769) in 50 μL of 50 mM MES buffer (pH 5.2); use promptly.

- Incorporate 20 μL of the EDC solution into the microsphere suspension.

- Mix gently end-over-end.

- Introduce biomolecule equivalent to 200-500 μg. Mix gently end-over-end or briefly vortex.

- Incubate for 2-4 hours at room temperature with gentle mixing.

- Centrifuge the mixture for 10 minutes at an appropriate G force. Note: The actual G forces required to pelletize the particles depend on the particle size. Retain the supernatant for determining the amount of bound biomolecule.

- Resuspend the microsphere pellet in 0.4 mL of 10 mM Tris buffer containing 0.05% BSA (pH 8.0).

- Repeat Steps 7-8 and combine supernatants for use in calculating bound biomolecules.

- Preserve conjugated microspheres at 4 °C in Tris storage buffer. Utilize conjugated particles promptly due to the degradable nature of PLGA.

References

- Brigger I, Dubernet C, Couvreur P. 2002. Nanoparticles in cancer therapy and diagnosis. Advanced Drug Delivery Reviews. 54(5):631-651. https://doi.org/10.1016/s0169-409x(02)00044-3

- Cho K, Wang X, Nie S, Chen Z, Shin DM. 2008. Therapeutic Nanoparticles for Drug Delivery in Cancer. Clinical Cancer Research. 14(5):1310-1316. https://doi.org/10.1158/1078-0432.ccr-07-1441

- Hillaireau H, Couvreur P. 2009. Nanocarriers? entry into the cell: relevance to drug delivery. Cell. Mol. Life Sci.. 66(17):2873-2896. https://doi.org/10.1007/s00018-009-0053-z

- Sharma HS. 2009. Nanoneuroscience and Nanoneuropharmacology. In Progress in Brain Research. .198. https://doi.org/10.1016/c2009-0-01918-7

- Van Eerdenbrugh B, Vermant J, Martens JA, Froyen L, Humbeeck JV, Van den Mooter G, Augustijns P. 2010. Solubility Increases Associated with Crystalline Drug Nanoparticles: Methodologies and Significance. Mol. Pharmaceutics. 7(5):1858-1870. https://doi.org/10.1021/mp100209b

- Moffatt S. Nanoparticle PEGylation for Cancer Therapy. MOJPB. 2(1): https://doi.org/10.15406/mojpb.2015.02.00037

About Merck

Our pursuit is progress for people everywhere. That's why we take a closer look at things, ask questions, and think ahead.

We've been around for more than 350 years, yet our majority owners are still the descendants of Friedrich Jacob Merck, the man who founded our company in Darmstadt, Germany in 1668.

From advancing gene-editing technologies and discovering unique ways to treat the most challenging diseases to enabling the intelligence of devices – the company is everywhere.

We are Merck. The only exceptions are the United States and Canada. Here we operate as EMD Serono in the Biopharma business, as MilliporeSigma in the Life Science business, and as EMD Performance Materials in the materials business.

Our life science business

We provide infinite solutions to solve the toughest problems in life science in collaboration with the global scientific community. Our tools, services, and digital platforms empower scientists and engineers at every stage, helping deliver breakthrough therapies more quickly.

Focus areas

With our three business units, we are a leading worldwide supplier of tools, high-grade chemicals, and equipment for academic labs, biotech, and biopharmaceutical manufacturers, as well as the industrial sector.

- Research Solutions provides our academic customers with the chemicals and tools needed to make scientific discovery easier and faster.

- Process Solutions provides drug manufacturers with process development expertise and technologies, such as continuous bioprocessing.

- Applied Solutions offers both testing kits and services to ensure that our food is safe to eat and our water is clean to drink.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.