Highly potent active pharmaceutical ingredients (HPAPI) are increasingly in demand, particularly in areas of precision medicine and anti-cancer therapeutics.

Image Credit: Powder Systems

These small molecules and biologics serve as the foundation for a range of innovative drug products, such as antibody-drug conjugates (ADC) and emerging drug substances aimed at treating autoimmune diseases. Notably, highly potent compounds now represent over 30% of the pharmaceutical industry’s drug pipeline.1

Despite the multifold opportunities offered by HPAPI development and manufacturing, extreme care must be taken during the process development phase. Potent APIs consist of highly toxic payloads, which can be extremely hazardous at low concentrations. The Occupational Exposure Limit (OEL) for ADCs, for example, is below 0.1 μg/m3.2

Knowing this, contract manufacturers and pharmaceutical companies must create appropriate engineering controls to guarantee safe handling and completely remove cross-contamination of HPAPIs.

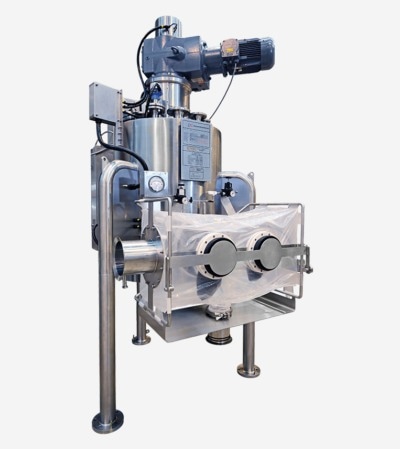

Agitated nutsche filter dryer (ANFD) systems with appropriate isolator designs provide the correct level of containment required for safe and effective HPAPI development.

Rigid Double Chamber Discharge Isolator for low nanogram containment performance. Image Credit: Powder Systems

Flexible Discharge Glovebag for OEB4 Applications. Image Credit: Powder Systems

Understanding ANFD containment

ANFD systems are present throughout the HPAPI pipeline, including intermediate and final product manufacturing. In either scenario, products with high-toxicity payloads are discharged from a plug and must be effectively contained, either prior to being looped back to an earlier phase of development or being filled into packaging containers.

Conventional ANFD systems contain a vessel with an opening piston valve to discharge products. However, this kind of design commonly requires manual intervention because of the residual product heel.

Naturally, this does not meet current regulatory standards for HPAPI manufacturing, and manufacturers would not want to discard this residual product as it could represent significant market value, potentially worth hundreds or thousands. The plug must be isolated to prevent exposure for operatives, but not all containment systems are designed equally.

Isolating the process utilizing a flexible container is one approach; however, this is not suitable for compounds classified above Occupational Exposure Band (OEB) 4. Increased containment needs a rigid isolator as well as air management capabilities.

For HPAPI containment, a single chamber glove box with a negative pressure environment and additional safety features can be suitable. However, there are further considerations to make in addition to physical isolation and air management.

In a single chamber configuration, various packaging arrangements like continuous liners, rapid transfer ports, or split valve technology can be employed.

Alternatively, a double chamber setup involves discharging the product into a primary chamber for packaging before transitioning into a secondary chamber. This represents a high-end yet highly effective solution for achieving optimal containment performance. Lastly, the most advanced approach to HPAPI manufacturing involves total process isolation.

Selecting the right HPAPI development solution

Selecting the appropriate containment method is crucial, but it involves a complex decision-making process.

It is imperative to minimize initial sources of contamination, emphasizing containment and air management around the discharge plug as a priority. However, equipment manufacturers must also anticipate critical process parameters to ensure the containment system operates effectively.

For instance, when discharging products as powder, it is essential to do so gently to control entry into the glovebox, reducing the risk of airborne powder and excessive coating of internal surfaces.

Additionally, certain stages of ANFD operation occur under vacuum conditions, which means utility lines (i.e., dust filters) need protection to avoid recirculating contamination downstream to ancillary systems.

Cleanability is another significant consideration. ANFD systems may offer limited flexibility if trace product retention is an issue; thus, operators must be able to clean the vessel safely without risking exposure to themselves.

Powder Systems Limited has designed ANFD solutions with enclosures suitable for the most potent drugs in development. PSL can anticipate crucial features that improve the filter drying process from both a performance and regulatory perspective.

One approach to achieving this is through meticulous vessel design aimed at eradicating retention areas. The objective is to enhance cleanability and flexibility, resulting in a safer and more adaptable instrument. The dust filter is similarly crafted with HPAPI production considerations, incorporating a safe change design to prevent particles from migrating downstream.

Finally, PSL offers a preventative maintenance program to maintain the performance of ANFD systems and guarantee process optimization and user safety. Proper housekeeping is the first rule of containment, meaning that maintenance of optical conditions is essential to operator safety.

PSL’s objective is to assist its customers in addressing the rising demand for high-potency compounds and maximizing their benefits in this dynamic marketplace, all while ensuring that operators are not exposed to any risks associated with potent chemicals.

References and further reading:

- https://www.chemanager-online.com/en/news/rise-hpapi-molecules

- https://www.pharmtech.com/view/understanding-containment

About Powder Systems

Powder Systems Limited (PSL) provides a full range of solid liquid separation solutions for filtration, drying, and processing from research and development activities up to larger commercial production scale.

Quality and innovation are central to everything they do. They are proud of their award-winning track record and have been working with industry partners for over 35 years.

PSL supports clients by developing solutions to overcome challenging manufacturing processes and provide first-class aftercare services.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.