Sponsored Content by AutomataReviewed by Louis CastelSep 17 2024

In a recent keynote at the Lab of the Future Europe event, Julie Huxley-Jones, Vice Presents of Scientific Digital and Tech at GSK, said: “No matter what transformation we have in the lab, we still have too high a failure rate when it comes to discovering new medicine.”

This quote highlights one of the most essential factors in successful lab automation: people must trust technology and its results if they are going to use it.

If automation is to become a key partner in experiment design and a core component of modern lab infrastructure, it is important that any automated process enhances reliability, supports users to understand points of failure, and can rapidly and intelligently respond to errors.

Automation that reduces experiment failure

One of automation’s primary goals is removing human variables from experiments. Automated processes have had great success in this area.

A clinical genomics lab partnered with Automata and achieved an 88 % reduction in manual errors while tripling its output through a fully automated, next-generation sequencing sample preparation workflow.

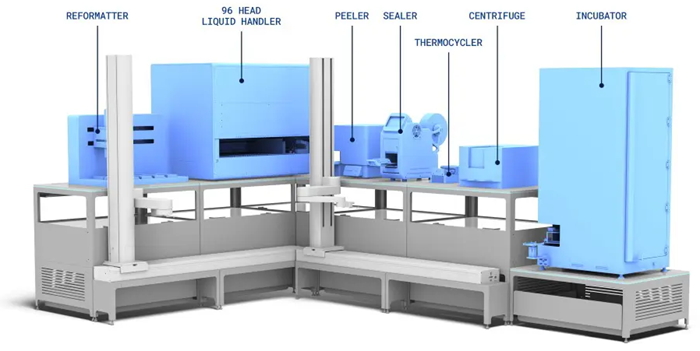

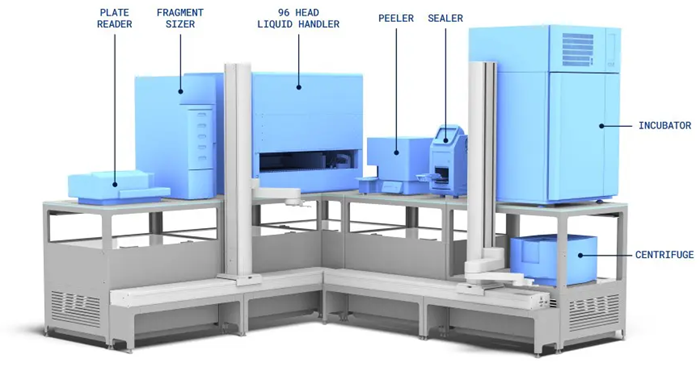

This system used the powerful LINQ lab automation platform, enabling the seamless robotic and digital integration of 16 individual hardware components to automate pre- and post-PCR testing workflows.

While this level of integration might seem overwhelming for a workforce not yet confident in using automation, the introduction of intuitive user controls, transparent data access, and pre-execution testing helps build trust in the system quickly.

A pre-PCR system on LINQ. Image Credit: Automata

A post-PCR system on LINQ. Image Credit: Automata

Transparent data

For labs to undertake root cause failure analysis, data files must be accessible. The LINQ platform does not lock audit logs, making it much easier to understand anomalies and errors.

The platform’s developer, Automata, is also a vendor-agnostic company, meaning that any equipment within the LINQ-automated workflows is digitally connected. Whether it is a single workflow in one lab or many workcells across a global network, users have the capacity to analyze and compare runtime data from any instrument.

It is also possible to import and export run instructions and related information, meaning that integrated SOPs can be used to limit the risk of operator error, even for new automation operators.

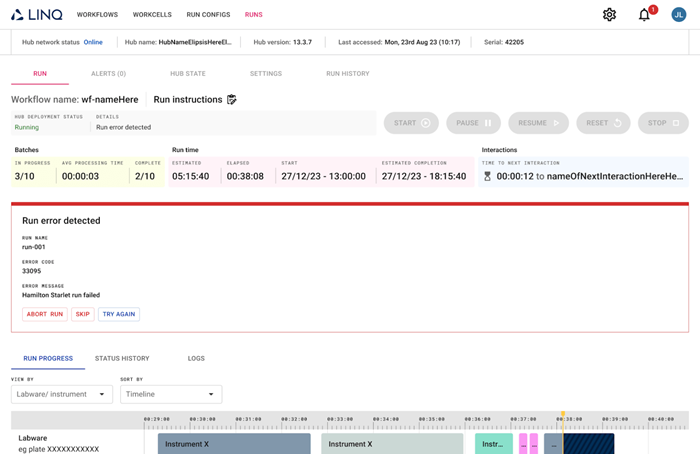

The LINQ Cloud features visible and downloadable run logs, enabling fully transparent and remote error analysis and handling.

Run logs are visible and downloadable in LINQ Cloud for transparent and remote error analysis and handling. Image Credit: Automata

Pre-execution testing

Allowing users to explore potential outcomes before they commit to using valuable resources is key to building trust in technology.

LINQ Cloud software enables users to simulate runs before execution, allowing them to preview the workflow schedule in advance. This pre-execution testing also helps identify potential bottlenecks, fostering trust in the sequence of automated actions and reducing the likelihood of avoidable failures.

Dynamic replanning scheduling

A range of lab scheduling programs is available on the market, but historically, customers have had to opt for either static schedulers—which provide run predictions based on known constraints—or dynamic schedulers, which can adapt to failures but do not provide that same upfront view.

Automata has developed a scheduler that delivers the best features of both types, meaning that if an issue is encountered, users can trust the automation to replan accordingly.

The platform’s unique architecture facilitates real-time dynamic execution while continually predicting outcomes and planning the most appropriate course of action to complete the workflow in question successfully.

A visual example of LINQ amending a run schedule. Video Credit: Automata

Parameterization

Parameterization is straightforward with LINQ. Instrument methods, time constraints, conditionals, data transfer events, and customizations are all visible to users, and it is possible to amend these during a workflow build.

LINQ leverages this data to determine the most effective route to completing the experiment in question. The platform’s scheduling engine will respond appropriately should any of these parameters change during a live run, dynamically rerouting to ensure delivery remains consistent.

The system's transparency and ability to operate in alignment with process needs will foster greater trust in automation as a reliable partner to the lab's staff. Users can be assured that their needs are met without constant intervention or monitoring.

Automation that responds to failure

Several contemporary automation solutions, including robotic, digital, or a combination of the two, boast some degree of error tracking and mitigation, but this has not been sufficient in the past.

In practice, the most important aspect is how a system actively overcomes errors. If a run is not kept on track, this can rapidly affect timelines, which can be extremely costly in high-throughput environments.

Automata believes that scientists should be afforded accurate walkaway time. As such, the company’s automation platform has several built-in ways of recovering when issues occur without the need for active staff monitoring.

Remote handling

LINQ uses cloud-based software that allows users to design, build, simulate, and execute workflows remotely. This ensures that the system can accommodate even global lab networks.

It also boasts built-in error notification and handling capabilities—critical features that inspire trust in the system's ability to deliver results regardless of whether operators are in the room.

If an issue arises, LINQ Cloud will instantly:

- Deliver email and in-app notifications highlighting the issue.

- Allow users to immediately triage and react to errors.

- Offer the option to remotely abort, repeat, skip, and pause any part of the workflow.

- Facilitate collaboration, ensuring the right team members, business partners, and the Automata success team can rapidly explore problems and address these via cloud accessibility.

Reallocating resources

Instrument parameters, or even a scheduler’s decisions, can be adjusted based on operators’ instructions, allowing workflows to be rerouted and appropriate actions to be reallocated to different instruments as needed. Users also retain the ability and capacity to intervene if necessary.

For example, the Scara robotic arms featured on LINQ will seamlessly work the unique transport layer, mimicking the flexibility of actions available where a scientist is actively tending the workflow.

The transport layer ensures the correct sample is delivered to the right instrument at the allocated time, while LINQ Cloud software tracks and logs every action and step.

Video Credit: Automata

Networked resources

All aspects of LINQ’s automation are connected on both a physical and digital level, meaning that every individual element across every automated workcell or workflow becomes a usable resource.

Should errors occur, LINQ can explore the entire interconnected network, affording users a myriad of ways to address errors and overcome bottlenecks.

If a workcell becomes unusable, the platform will reallocate any at-risk actions to other systems with capacity, allowing the run to continue.

Automation with LINQ allows labs to become increasingly connected, making the journey from automating single workflows to developing a fully automated lab network easier.

Three LINQ systems connected to one central cloud-based control hub. Image Credit: Automata

Field support

When the automation developer is required to help solve issues that operators cannot, users working with Automata have access to the company’s field services team of programmers, engineers, and scientists.

The company’s comprehensive support team is on hand to provide fast on-site and remote support as needed. Automata can triage issues remotely or on-site, and secure on-site backup solutions are available should internet outages occur. These backups ensure that a process will never be offline or far from support.

Honesty from automation vendors

Automation is not infallible, but it does limit the risk of human errors such as mislabelling, contamination, use of incorrect agents, and improper recording of results.

LINQ’s end-to-end automated workflows include integrations between many physical and digital components, but these require some human input.

Many labs run LINQ without issues, but no automated system can claim a 100 % run success rate.

Automata is focused on developing reliable systems and maintaining uptime for its clients. Features have been implemented to support the system’s users to understand when and why errors occur. More importantly, the system features several built-in tools to overcome these.

Automation allows tech-scientist relationships to become partnerships. Instruments should automatically perform the manual, time-consuming elements of research while lab staff are afforded the data and time needed to research, analyze, and discover.

Developers must not shy away from the problems that still exist with automation. A combined effort is required between scientists, industry, vendors, and automation designers to make automation a central component of every lab. Automata sees this collaboration as vital for effectively responding to challenges.

Acknowledgments

Produced from materials originally authored by Automata Technologies Ltd.

About Automata

About Automata

Born from a world-leading research lab, Automata is making total workflow automation accessible to labs frustrated by the limitations of their own environment.

Accelerating the innovation evolution

When two architects from Zaha Hadid’s research lab first approached robotics, their idea was to explore applications specific to architectural engineering.

But they soon discovered that modern automation wasn’t just unnecessarily complex – it was actively restricting innovation. And not just within their industry – within many others too. It was clear that robotic automation was a field where their combined experience in computational research and design could make a real difference. Assembling a team of industry experts, Automata was founded, with a clear aim: to enable new opportunities for innovation with automation.

A clearer path to progress

Automata’s focus narrowed on an industry where they felt their expertise could have the most impact – life sciences, and particularly within biolab environments.

Since then, the team has been working closely with leading pathology labs to pioneer protocols that enable labs to scale with precision

Automata Labs is the product of that philosophy – simplifying lab environments and empowering the people working tirelessly in the pursuit of progress.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.