Engineers working in the life sciences sector are facing increasing pressure to improve throughput and reduce total cost of ownership.

Image Credit: Fluid Metering, Inc.

Syringe pumps or inline piston pumps are typically used in dispensing systems, but these pumps tend to be slow and require regular maintenance over the life of the pumps to maintain satisfactory throughput.

Fluid Metering has developed the FENYX, a groundbreaking variable dispense pump that is able to increase throughput and decrease costs in the majority of syringe pump applications.

Fluid Metering’s CeramPumps® have been used throughout the life sciences industry for more than 60 years, but until now, these pumps have been limited to precision dispensing with a fixed volume.

The FENYX variable dispense pump allows users to alter the pump’s dispense volume in the same way as is possible with a syringe pump or inline piston pump, but while leveraging all the advantages of using a ceramic rotating reciprocating piston.

FENYX Versus Syringe Pump

The FENYX offers a number of advantages over traditional syringe pumps:

- Increase throughput by 10x-40x with the highest degree of accuracy and precision

- Self-priming up to 15 ft H2O

- Adjustable dispense volume 2-1150 µL/stroke

- High resolution 0.037 µL/step dispense volume adjustment

- Valveless design with one moving component

FENYX® vs. Syringe

Video Credit: Fluid Metering, Inc.

The FENYX is an ideal drop-in replacement for syringe pumps, especially for OEMs seeking high uptime and zero maintenance. For those considering a syringe pump in their design, the FENYX offers solutions to key concerns, including the below.

High Maintenance Requirements Equate to High Cost of Ownership

The Problem:

Syringes wear over time, leading to a decline in volumetric and positional accuracy and precision.

Syringe pumps generally require servicing following 100-250 K cycles. Depending on the pump’s duty cycle, this may involve sourcing replacement parts every few weeks or months. Recalibration could also be necessary, even in cases where the syringe pump is replaced entirely.

All of these maintenance requirements result in considerable additional costs and significant losses in working time.

The Solution:

The FENYX features a maintenance-free rotating reciprocating piston design. The pump’s ceramic parts are both chemically inert and dimensionally stable, meaning that they will not stretch, distort, or change shape over time.

Because it features a single moving component, the FENYX undergoes little to no wear, meaning that it will remain maintenance-free throughout the lifetime of the instrument.

Expensive Supporting Fluidics

The Problem:

OEMs often have to include expensive supporting fluidic architecture in order to maintain high throughput.

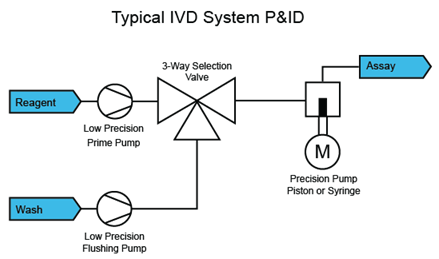

Image Credit: Fluid Metering, Inc.

For example, requiring separate pumps to prime, flush, and dispense requires extra lines of often frail tubing, additional risky leak points, and increased OEM machine size.

The Solution:

The FENYX is valveless and able to self-prime 10x-40x faster than a syringe pump, helping OEMs eliminate unnecessary fluidic components such as flushing pumps, prime pumps, selector valves, and tubing.

Priming Low-Volume Syringes

The Problem:

Syringe pumps are prone to trapping substantial amounts of air between the tip of the syringe and the valve. This air can only be removed through multiple priming cycles in small-volume syringe pumps, slowing down the priming process and creating problematic delays in time-sensitive applications. Syringe pumps also necessitate the use of a separate pump to prime.

The Solution:

The FENYX can be rapidly self-primed at higher dispense volumes before being adjusted to accommodate the target dispense. This removes any risk of bubble entrapment while addressing the priming issues common to smaller syringe barrel sizes.

Restrictions with Flow and Viscous Mediums

The Problem:

Syringe pumps work by exerting linear force on a plunger in order to dispense fluid. This means that highly viscous mediums cannot be handled because they tend to create more intense friction than the pump can accommodate.

Attempting to pump viscous fluids will lead to rapid pump degradation and failure, with the syringe pump’s flow rate constricted even with lower-viscosity fluids. In these cases, throughput is fully dependent on the syringe diameter.

The Solution:

The FENYX variable dispense pump has been developed with more robust components. It is able to accommodate more powerful motors, meaning that it can overcome the resistance required to accommodate a wider range of fluid viscosities with no performance degradation.

The FENYX draws fluid from a reservoir as required, meaning that its flow rate can operate continuously at a wider range, spanning from 1 mL per minute at 1 rpm up to 400 mL per minute at 1000 rpm.

Non-Contact Dispensing

The Problem:

Syringe pumps lack the capacity for non-contact dispensing, requiring life science OEMs to use touch-off or submersion methods in order to dispense single microliter volumes.

This approach necessitates regular probe tip changes or washing in order to prevent cross-contamination, increasing costs and reducing throughput.

The Solution:

The FENYX variable dispense pump is able to accommodate non-contact dispensing capability down to 4 µL while maintaining excellent accuracy and precision. This removes the need for washing or probe tip changes, reducing system costs and improving life science OEMs’ throughput.

Improvements

There are limitations to the viable improvement of syringe pumps, but variable dispense pumps have been specifically designed to ensure flexibility. The FENYX variable dispense pump boasts a number of improvements over its predecessor, the FVD model:

- A calibratable flag, featuring updated home positioning and dispense options. This means the pump does not have to be recalibrated when changing dispense volumes, and applications will offer the same functionality pump to pump, with a pump variation of less than 0.5 % of max dispense volume.

- An anti-backlash mechanism reduces dispensing variation when the linear actuator changes direction.

- An electronic encoder confidently informs the system of the linear actuator’s location, removing the need to guess if the pump has taken the correct number of steps.

- Sensor orientation has been changed so that the flag goes through the sensor without touching it.

- A corrosion-resistant internal spring steel (1065 spring steel to 301 stainless steel) connector links the variable head to the actuator, meaning that no maintenance is required.

- The linear sensor is also dual-mounted, ensuring a stable home position that will not be impacted by manipulation of the pump during shipping.

Applications

The FENYX is the ultimate long-term solution for applications requiring continuous operation and more rapid, accurate, and reliable results.

The FENYX can accommodate a much more diverse array of applications than a syringe pump, with Fluid Metering’s CeramPump® technology seeing routine use in the following applications:

- Analytical instruments

- Liquid chromatography

- Gas chromatography

- Flow cytometry

- In vitro diagnostics (IVD)

- Clinical diagnostics

- Genomics and proteomics

- Sample preparation

- Drug discovery

- Liquid handling systems

- Mass spectrometry (MS)

- Bioprocessing

Acknowledgments

Produced from materials originally authored by Blake Webb from Fluid Metering, Inc.

About Fluid Metering, Inc.

Fluid Metering, Inc. (FMI) is a worldwide leader in life science pumps and dispensers, having pioneered the first valve-less piston pump over 64 years ago. With specialized expertise in fluidics and applications, Fluid Metering, Inc. supports instrument developers in tackling complex fluidic challenges.

Committed to innovation through collaboration, Fluid Metering, Inc. advances health, sustainability, and quality of life. ISO 9001:2015 certified.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.