GelMA is a polymerizable hydrogel material generated from natural extracellular matrix (ECM) components. Gelatin has become popular for tissue engineering applications due to its low cost, availability, and preservation of natural cell-binding motifs.

Alginate is a naturally occurring polymer that is commonly used in bioprinting applications since its printability can be readily adjusted by changing the polymer density and crosslinking with calcium chloride (CaCl2). To promote cell adhesion and differentiation, alginate is frequently mixed with gelatin.

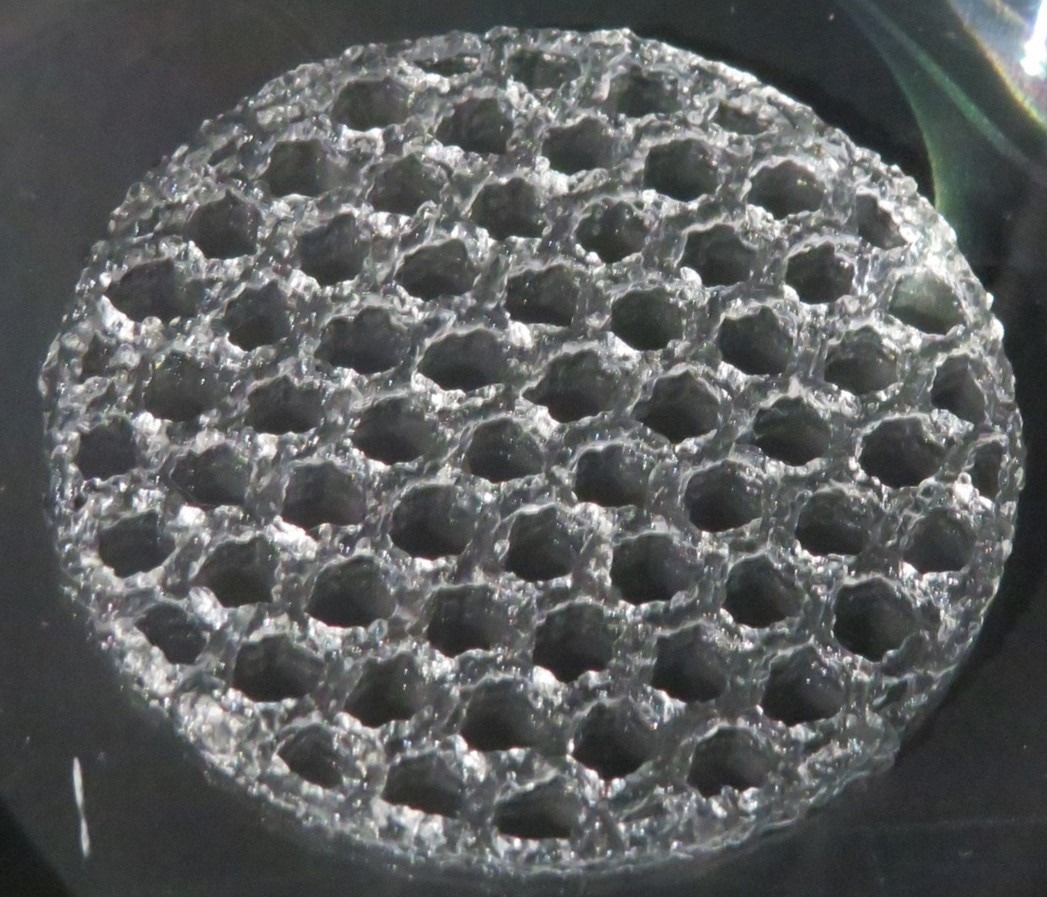

Adjusting the degree of functionalization and polymerization conditions allows for temporal and geographic control of the crosslinking reaction, allowing for the construction of hydrogels with unique patterns, 3D structures, and morphologies.

Image Credit: Merck

Properties

Source: Merck

| . |

. |

| Form |

Viscous liquid (gel) |

| Quality Level |

100 |

| Impurities |

<5 CFU/g Bioburden (Total Aerobic)

<5 CFU/g Endotoxin (fungal)

<50 EU/mL Endotoxin |

| Color |

Pale yellow to colorless |

| pH |

6.5-7.5 |

| Viscosity |

10-40 cP(37 °C) |

| Application(s) |

3D bioprinting |

| Storage temp. |

2-8 °C |

Application

Bioinks based on gelatin methacrylate have been employed in the following bioprinting applications:

- Epithelial

- Endothelial

- Cardiac valve

- Skin

- Tumors

- Osteogenic

- Chondrogenic

- Hepatic

- Adipogenic

- Vasculogenic

TissueFab® bioink Alg (Gel)ma -UV/365 nm, low endotoxin is a ready-to-use bioink that is made for extrusion-based 3D bioprinting and subsequently crosslinked with calcium chloride and 365 nm light while having low endotoxin levels, good cell viability, and printability. This bioink is biodegradable, compatible with human mesenchymal stem cells (hMSCs), and can be utilized with most extrusion-based bioprinters.

The exact production of 3D cell models and tissue constructions for research in 3D cell biology, tissue engineering, in vitro tissue models, and regenerative medicine is made possible by TissueFab® bioink Alg (Gel)ma–UV/365 nm, low endotoxin.

Features and benefits

- Ready-to-use formulation designed for maximum printing fidelity and cell survival, removing the need for the time-consuming bioink formulation development procedure

- MilliporeSigma 3D Bioprinting Scientists designed and tested step-by-step techniques; no prior 3D bioprinting experience is required

- Appropriate for various extrusion-based 3D bioprinter models

- The methacrylamide functional group can also be employed to regulate the physical properties of the hydrogel, such as pore size, degradation rate, and swell ratio