Gelatin methacryloyl (GelMA) is a polymerizable hydrogel material derived from natural extracellular matrix (ECM) components. It is highly desirable for tissue engineering due to its cost-effectiveness, abundance, and retention of natural cell binding motifs.

Laminin, a multidomain trimeric glycoprotein in the ECM, is a key non-collagenous component of the basal lamina. This protein supports adhesion, proliferation, and differentiation, with its structure consisting of A, B1, and B2 chains connected by numerous disulfide bonds.

Isolated from the mouse Engelbreth-Holm-Swarm tumor, laminin proteins play a vital role in the structural scaffolding of animal tissues. They interact with type IV collagen through entactin and perlecan and attach to cell membranes via integrin receptors, dystroglycan glycoprotein complexes, and Lutheran blood group glycoproteins.

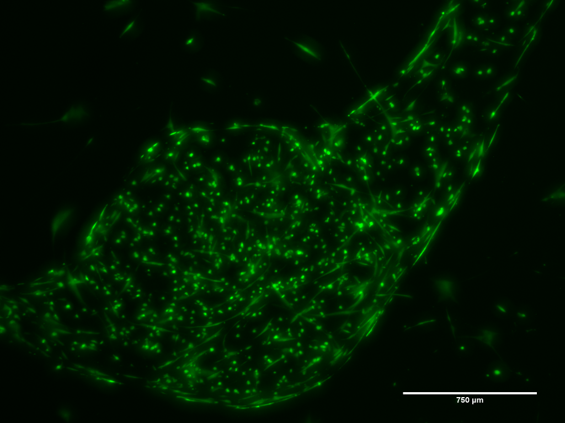

Image Credit: Merck

Properties

Source: Merck

| . |

. |

| Form |

Viscous liquid (gel) |

| Size |

10 mL |

| Impurities |

<5 cfu/mL Bioburden

<50 EU/mL Endotoxin |

| Color |

Pale yellow to colorless |

| pH |

6.5-7.5 |

| Viscosity |

3-30 cP |

| Application(s) |

3D bioprinting |

| Storage temp. |

−20 °C |

Application

The incorporation of photocrosslinkable methacrylamide functional groups into GelMA enables the production of hydrogels that are biocompatible, biodegradable, and non-immunogenic. These hydrogels remain stable under biologically relevant conditions and support cell adhesion, spreading, and proliferation.

Gelatin methacrylate-based bioinks have been employed in the 3D bioprinting of various tissues and structures, including chondrogenic, osteogenic, adipogenic, hepatic, vasculogenic, endothelial, epithelial, cardiac valve, skin, tumor, and more.

Laminin features active domains facilitating collagen binding, cell adhesion, heparin binding, and neurite outgrowth fragments. In tissue engineering applications, laminin is useful in developing corneal tissues, organoids, and treatments for neurodegenerative diseases.

Features and benefits

Beyond its rapid gelation properties, the methacrylamide functional group can regulate various physical characteristics of hydrogels, including pore size, degradation rate, and swell ratio. By modifying the degree of functionalization and adjusting polymerization conditions, precise control over the crosslinking reaction can be achieved.

This temporal and spatial control enables the creation of hydrogels with distinctive patterns, 3D structures, and morphologies, making them highly versatile in tissue engineering and beyond.