Caused by the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), the coronavirus disease 2019 (COVID-19) pandemic continues to spread across the globe. With new variants emerging to global dominance with heightened infectivity, the world grapples with skyrocketing cases. More than 109.88 million cases have been reported since the virus was first detected in December 2019, and over 2.42 million have lost their lives.

The pandemic has taken a toll on many healthcare systems globally. Many countries have faced challenges due to the lack of hospital beds and intensive care unit (ICU) beds for COVID-19 patients. The most significant difficulty they have faced is a lack of medical equipment in hospitals to cater to the inordinately large flow of inpatients. These include respirators that are important for respiratory support.

A team of researchers has explored the techniques of 3D printing for crucial equipment needed by healthcare systems to adequately manage the burden of care brought about by the COVID-19 pandemic. The team also noted other uses 3D printing could have in aiding the global fight against the pandemic.

COVID-19 supply challenges

At the beginning of the pandemic, many countries were not prepared for the influx of COVID-19 patients. Many hospitals lacked adequate hospital beds and equipment to cope with the surging number of cases.

There was also a widespread shortage of personal protective equipment (PPE) – including an inadequate supply of surgical gloves, masks, disinfectants, and testing kits. Due to this shortage, many healthcare workers were left without protection while tending to patients' needs.

Respirators were lacking during the pandemic's peak, which is critical for supporting the patients' respiratory system. There are a small number of respirators, which are emergency devices that help patients breathe for a short period.

What is 3D printing?

To cope with the shortage of equipment, 3D printing can help to render three-dimensional prints realized as physical objects via a printer. Low-cost desktop 3D printers help make 3D models and guides, which have been used to manufacture equipment used in the battle against COVID-19.

The 3D printing method, also known as the layered production (AM) method, is based on the theory of layered production of many materials like metal, living cells, powders, ceramics, and liquids. The technique produces several intricate 3D geometrics using a computer-aided design (CAD) model or a computed tomography (CT) scan.

The 3D method can also create personalized organ and scaffold models to produce and print defective areas directly. The technique offers new possibilities in medicine, particularly when it comes to diagnostics and quickly identify potential organ donors.

The study

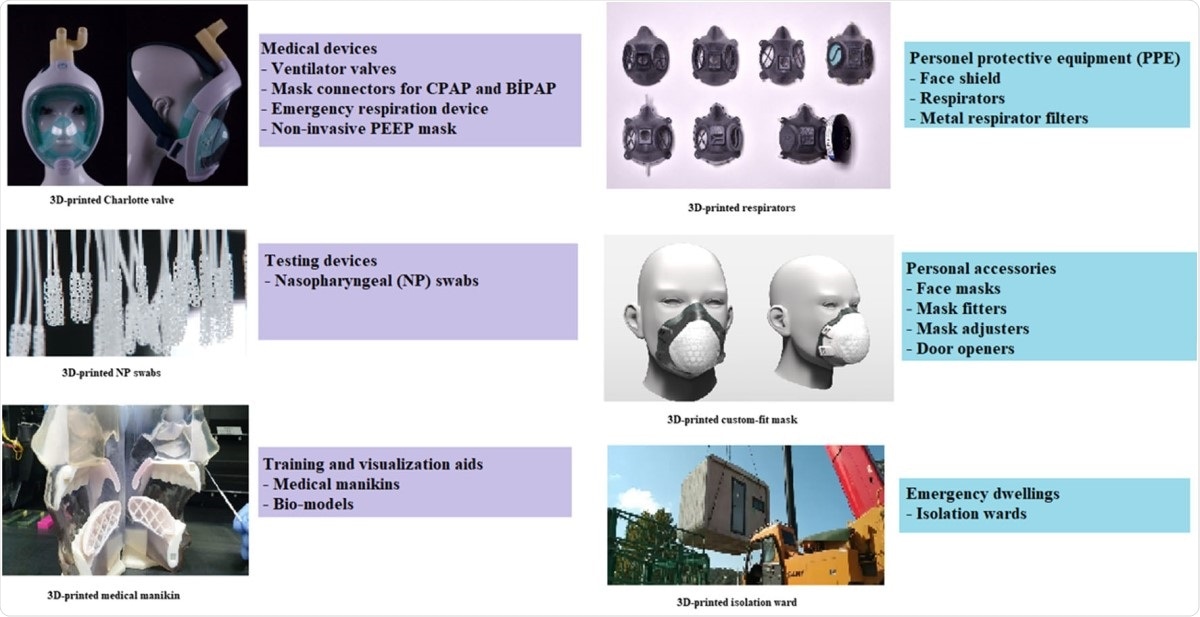

In the study, published in the journal Emergent Materials, the researchers identified the role of 3D printing in COVID-19. During the pandemic, over 100 various 3D printable PPE designs have been used.

The study highlights studies about 3D printing and its use in the current global health crisis. Several internet libraries like ScienceDirect, Google Scholar, PubMed, and Google News were explored to search studies with keywords like "3D print", "COVID-19", and "materials."

The team search studies from November 2019 onwards, the date when the disease was assumed to have started. They found 195 results in ScienceDirect and 119 results in PubMed. Over 7,500 results were found in Google Scholar, but there were repeated results.

Equipment that are printed by 3D for COVID-19

The team found that 3D printing has been used to produce PPE, including face masks, face shields, and additional accessories like mask extenders. The method has also been used in diagnostic tools like swabs, ventilator devices, splitters, 3D printing lung models, endotracheal tube clamp, door opener, and isolation wards.

The 3D printing method can help save many lives, but it has both benefits and challenges.

In 3D printing, there is freedom of design, depending on the health worker’s or patient’s needs. It also allows for mass customization, waste reduction, and the ability to manufacture complex structures.

It has limitations like high costs, limited applications in large structures, and limitations of materials. Despite these, the 3D printing method can open the doors for the technology to be used in various clinical contexts.