Researchers have been sacrificing the precision of their liquid transfers for efficiency, ease of use, and speed, since the inception of the variable volume pipette in the 1960s.

Yet, a new trend towards reducing reaction volumes in genomics laboratories has called into question the capabilities of various liquid handling solutions, particularly since lower volumes usually increase the effect of liquid handling imprecision on experimental results.

The reproducibility of data has never been so salient and highly scrutinized, with drug discovery and precision medicine relying so heavily on the findings published by translational genomics laboratories in biotechnology and academia.

Today, researchers typically regard automated workstations as the most reproducible liquid handling solutions, as automated liquid handling (ALH) systems take away many of the challenges that are associated with user-variability.

Researchers examine the volumetric performance of these devices chiefly by measuring the imprecision of liquid transfers, expressed quantitatively through coefficients of variation (CVs).

ALH platforms usually dispense very precisely, and published CVs for target liquid deliveries in the range of tens to hundreds of microliters (µL) are typically below 1%. Yet, as target volumes approach 1 µL, for most ALH systems these specifications deteriorate.

In fact, the most frequently used liquid handling platforms publish specifications including CVs which are as high as 6% at 0.5 µL (Table 1). FORMULATRIX® and Artel present this article to showcase the precision of the MANTIS® Liquid Handler, a novel solution designed to supplement traditional liquid handling platforms.

Table 1. Published CVs of two common ALH systems (10 μL disponsable tips) compared to ISO 8655 maximum permissible errors for manual pipettes. Source: FORMULATRIX

| Volume |

Traditional Liquid Handler #1 |

Traditional Liquid Handler #2 |

ISO 8655 Maximum Permissible Random Error1 |

| 10 µL |

1.0% |

0.8% |

1.5% |

| 5 µL |

1.5% |

No Spec |

2% |

| 1 µL |

4.0% |

No Spec |

5% |

| 0.5 µL |

6.0% |

5.0% |

No Spec |

| 0.1 µL |

No Spec |

No Spec |

No Spec |

Researchers can increase experimental reproducibility in genomics workflows that involve dispensing small volumes of valuable reagents with a high degree of precision by implementing the MANTIS.

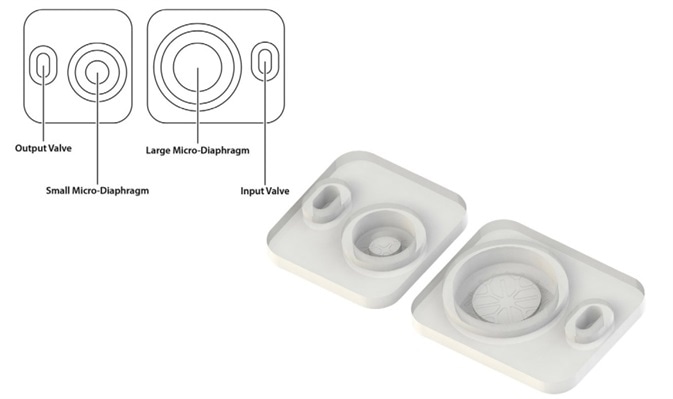

A patented microfluidic valve cluster is at the core of the MANTIS. This measures and dispenses discrete volumes of liquid, as seen in Figure 1. Each valve on the silicone valve cluster is opened and closed by pressure and vacuum.

The positive displacement chips have two micro diaphragms that can fill and dispense as quickly as 10 times per second. The high volume (HV) chips contain 1 and 5 µL diaphragms, while the low volume (LV) chips contain 0.1 and 0.5 µL diaphragms.

The Continuous Flow (CF) chip uses a distinct valve based technology which enables the dispensing of volumes from 5 µL to 2000 µL in a continuous stream.

Figure 1. FORMULATRIX® patented microfluidic dis-pensing technology. Image Credit: FORMULATRIX

Materials

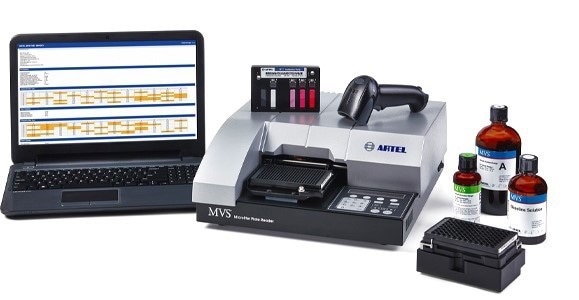

- Artel MVS Calibrator Plate (Figure 2)

- Artel Sample Solutions (Figure 2)

- Artel ELx800 NB Plate Reader (Figure 2)

- Q-Instruments Bioshake 3000 (Figure 2)

- 12x Artel 96-well Verification Plates

- 21x Artel 384-well Verification Plates

- HONEYWELL Xenon 1902 Barcode Reader (Figure 2)

- Grant-bio LMC-3000 Laboratory Centrifuge

- FORMULATRIX MANTIS Liquid Handler (Figure 3)

Figure 2. Artel Multichannel Verification System (MVS). Image Credit: FORMULATRIX

Figure 3. FORMULATRIX® MANTIS® Liquid Handler. Image Credit: FORMULATRIX

Methods

In this experiment, the MANTIS Liquid Handler delivered target volumes of Artel Sample Solutions into each well of meticulously characterized Artel 96- or 384-well Verification Plates.

The Artel MVS read the concentration of the sample solution after centrifugation and mixing, and supplied CV value for each plate through the graphical user interface of the Artel MVS Software. In order to provide a compelling set of liquid deliveries one discrete target volume was chosen for each 96- or 384-well microplate.

In order to give a comprehensive review of the liquid handling imprecision associated with the MANTIS, eleven target volumes were selected over the three microfluidic MANTIS chip types. Each run for each target volume was tested in triplicate to ensure statistical significance, in accordance with best practices.

All tests performed with the CF chip type used Artel 96-well Verification Plates. All volumetric tests performed with the HV and LV chip types used Artel 384-well Verification Plates.

To accommodate the 200 µL dispense volume and ensure consistency across all testing for this chip type, lower density plates were used for all CF testing.

Results

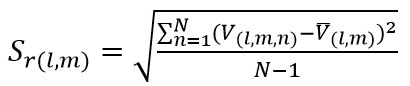

As shown in Formula (1), random error of each run was evaluated by calculating the standard deviation of the series of 96- or 384- measured volumes under repeatability conditions.

|

(1) |

where

Sr(l,m) - is the random error of channel ‘l’ during run ‘m’

V(l,m,n) - is a single measured volume

V(l,m) - is the average of all measured volumes from channel ‘l’ during run ‘m’

N - is the number of replicate deliveries in the run

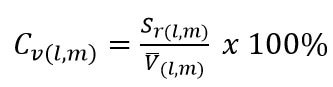

This standard deviation was utilized to calculate the coefficient of variation expressed as a percentage, as shown in Formula (2).

|

(2) |

where

Cv(l,m) - is the coefficient of variation of channel ‘l’ during run ‘m’

CVs were averaged over three separate runs for each target volume using a root-mean-squares approach as shown in Formula (3) below. This formula was chosen because the number of replicate deliveries was consistent across each run.

|

(3) |

where

Cv(l) - is the coefficient of variation of channel ‘l’ combining data from multiple runs

M - is the number of runs included in the average2

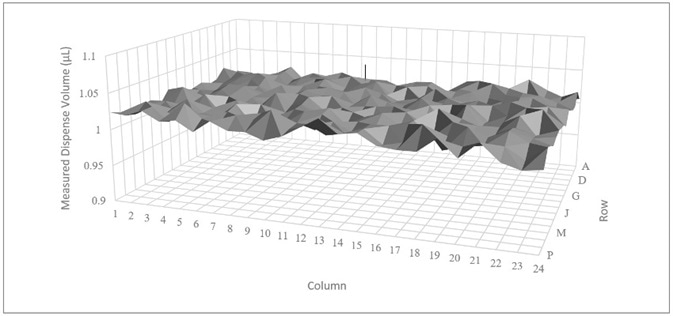

Over the entire volume range, all CVs, and Root Mean Squared (RMS) of CVs, were less than or equal to 1.5% (Table 2, Figure 4).

Table 2. Measured Performance of the FORMULATRIX® MANTIS® Liquid Handler. Source: FORMULATRIX

| LV Chip* |

CV(1,1) |

CV(1,2) |

CV(1,3) |

CV(1) |

| 0.1 µL |

1.3% |

1.5% |

1.4% |

1.4% |

| 0.5 µL |

0.5% |

0.5% |

0.6% |

0.5% |

| 1 µL |

0.4% |

0.4% |

0.4% |

0.4% |

| HV Chip* |

CV(1,1) |

CV(1,2) |

CV(1,3) |

CV(1) |

| 1 µL |

0.8% |

0.8% |

0.8% |

0.8% |

| 5 µL |

1.1% |

1.1% |

1.1% |

1.1% |

| 10 µL |

0.5% |

0.6% |

0.6% |

0.5% |

| 25 µL |

0.4% |

0.4% |

0.4% |

0.4% |

| CF Chip* |

CV(1,1) |

CV(1,2) |

CV(1,3) |

CV(1) |

| 25 µL |

0.4% |

0.3% |

0.3% |

0.3% |

| 50 µL |

0.3% |

0.5% |

0.3% |

0.4% |

| 100 µL |

0.2% |

0.3% |

0.3% |

0.3% |

| 200µL |

0.2% |

0.2% |

0.2% |

0.2% |

Figure 4. Measured dispense volumes for a single run with target volume of 1 μL (HV Chip CV(1,3)). Image Credit: FORMULATRIX

Conclusion

The reproducibility of experiments between genomics labs can be hugely influenced by the imprecision of liquid transfers, particularly at low nanoliter-scale volumes.

As seen in the data published in this article, the MANTIS boasts CVs well below 2%, even at volumes as low as 0.1 µL, supplying researchers with a solution that facilitates the production of trustworthy results in highly sensitive techniques like Next Generation Sequencing (NGS) and qPCR.

As a growing number of researchers move to sub-10 µL reaction volumes in their genomics workflows, it will become more vital than ever before to ensure highly precise liquid handling within these volume ranges.

In order to get CV’s under 2% across the entire pipetting range, the MANTIS can be added to any traditional liquid handling workstation easily.

References

[1] ISO 8655-1:2002(en), Piston-operated volumetric apparatus - Part 1: Terminology, general requirements and user recommendations

[2] ISO IWA 15:2015, Specification and method for the determination of performance of automated liquid handling systems.

Acknowledgments

Produced from materials originally authored by Kristi Allen from Artel and Thomas Rawlins and Dmitry Rodionov from Formulatrix.

About FORMULATRIX

FORMULATRIX® was established in 2002 to provide protein crystallization automation solutions. Since then, we've started developing other laboratory automation solutions including the next generation of liquid handlers using microfluidic technology.

Headquartered in Bedford, Massachusetts, we supply software and robotic automation solutions to leading pharmaceutical companies and academic research institutions around the world. Our team works tirelessly to provide the best products in the industry with support that is second to none.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.