Without a sieve or a mill, pharmaceutical tablet manufacture is almost impossible. These are required whenever active and inactive materials are handled, when tablets or other products are made. Milling and sieving equipment are used to reduce the size of particles.

This fulfills two purposes: Firstly, it increases the particle surface area, which accelerates the breakdown process. Secondly, it evens out particle size disparities so that mixing is homogenous.

Image Credit: BJ Day Stock/Shutterstock.com

Milling and sieving equipment are important in pharmaceutical manufacturing because they are versatile.

They can be integrated into complex manufacturing lines, such as filling/emptying or transferring activities at process machines or filling and decanting containers. The versatility of mills and sieves, as well as the fact that the equipment requires relatively little space, are deciding factors in their use and functionality.

These devices' small footprints are especially useful in pharmaceutical clean rooms, where space is limited. Furthermore, several sieve systems and mills include built-in lifting columns, allowing them to be integrated into nearly any process scenario.

Machine mobility is another aspect that improves process efficiency. They can be readily transported or disassembled for use or cleaning purposes.

Mills and sieves, on the other hand, are always evolving and being improved. In addition to certain current trends, this article discusses how introducing modern hammer mills increased production efficiency.

Conical sieving machine

Pharmaceutical components are reduced to consistent sizes using conical sieve machines. They can also be used to mix, sieve, and disperse materials. They come in various sizes, including laboratory equipment and high-capacity systems.

Compared to alternative milling technologies on the market, the sieve gives various production benefits: It operates silently, creates a narrow distribution of particle sizes, and provides significant design flexibility and capacity.

This indicates that a sieving system of this type may process low-density materials at a 50 percent higher throughput than conventional mills.

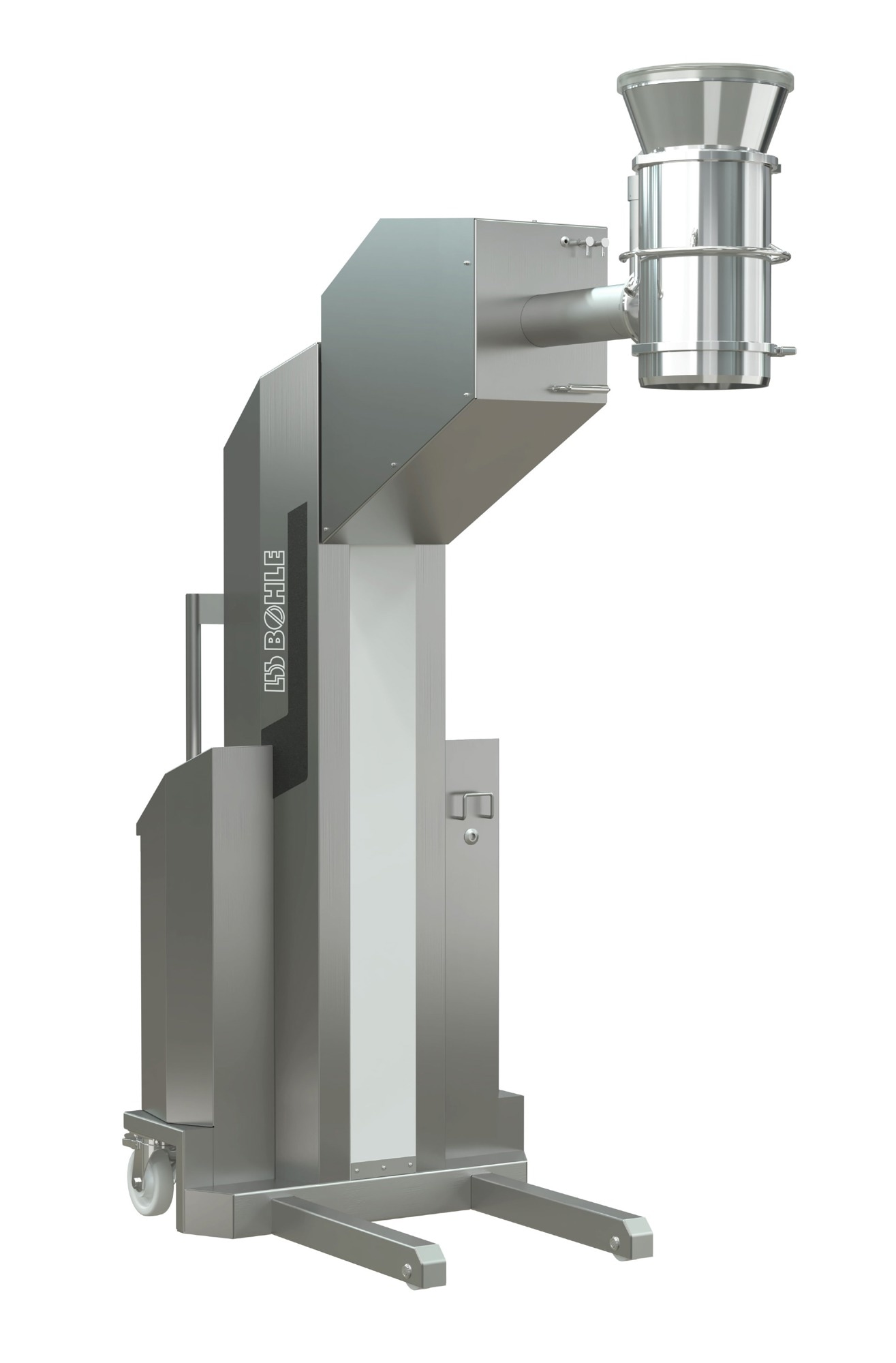

Figure 1. Bohle Turbo Sieve BTS 150. Image Credit: L.B. Bohle Maschinen und Verfahren GmbH

The patented Turbo Sieve BTS from L.B. Bohle Maschinen und Verfahren GmbH (Ennigerloh) is used for particle size calibration, resulting in an ideal particle size distribution.

The use of various conical sieve inserts (hole sieves and friction sieves) allows for the processing of dry and moist goods at speeds ranging from 150 to 1500 revolutions per minute. This allows for product capabilities of two to three tons in one hour.

Operators employ an easy-to-use 7-inch touch panel with access to user management, recipe management, PDF batch print management, and a USB interface. The explosion-proof Turbo Sieve can also be utilized in applications that require ATEX compliance.

The sieve's hygienic design facilitates manual cleaning. The sieve container can be easily removed using the bayonet mount and clamp ring combination, making it incredibly simple to clean each individual component.

The sieve housing can be supplied with cleaning nozzles for simple WIP cleaning, allowing material residue to be swiftly removed from inside the sieve container.

The scope of delivery includes cleaning nozzles on the sidewalls of the sieve insert and below the angled drive. The cleaning fluid is supplied by a central water supply source.

Figure 2. Easy operation via touch panel. Image Credit: L.B. Bohle Maschinen und Verfahren GmbH

Hammer mills

Hammer mills (also known as turbo mills) are ideal for research and development, batch production, and continuous manufacturing. They reduce powder, agglomerate, and granulate sizes.

Hammer mills are particularly useful in applications that require precision particle reduction for difficult-to-mill active chemicals and other compounds. They are also used to re-mill shattered tablets.

Tablets that have already been made are inspected and may fail to fulfill the customer's criteria for a number of reasons. Such criteria include flaws in their appearance or a lack of the appropriate weight or hardness.

If the tablet does not meet the criteria, the manufacturer can re-pulverize and reuse the materials using the hammer mill. Re-milling tablets and recycling materials in production ultimately lower reject rates and boost productivity.

Figure 3. Bohle Turbo Mill BTM 150. Image Credit: L.B. Bohle Maschinen und Verfahren GmbH

Hammer mills, such as L.B. Bohle's BTM series (Bohle Turbo Mill), can produce up to 1500 kg/h at speeds ranging from 600 to 6000 rpm. To accomplish this, the BTM includes an automatic dispenser unit (rotary feeder).

This enables the operator to feed the material into the milling chamber uniformly and without overburden. Furthermore, these automatic feeder devices may regulate the powder flow in the grinding chamber. Less heat is generated, and the procedure can be repeated with the same settings.

The internal rotor features two sides, each with a different function to support applications with wet or dry goods. The knife side grinds sticky substances, and the hammer side breaks hard and crystalline goods.

The size of the sieve used in a hammer mill determines the particle size. The BTM offers a variety of sieve inserts that can reduce the material size to as small as 0.1 mm.

An application example

Previously, cell culture developers employed ball mills to lower the particle size of their first blends. The ball milling technique is time-consuming and employs ceramic balls in a tumbling drum to crush the products. After a batch is processed, the mill and its hundreds of ceramic balls must be cleaned.

This cleaning process may take up to a week. During this period, the mill cannot be used and is unavailable to customers who request a user-defined, rapid batch of powder.

A manufacturer of such cell cultures was looking for a mill that would allow them to more easily and efficiently meet the needs of their biopharmaceutical customers.

They also wanted the mill to be portable and take up little space. The device should be able to be removed from the initial production area for cleaning to make place for future manufacturing processes. The customer also specified product-specific mill specifications, such as temperature, particle, and batch size.

Cell cultures necessitate small particle sizes for optimal resolution rates. As a result, up to 50% of the batch must be smaller than 100 micrometers.

The medium is highly vulnerable to temperatures above 37 °C, as the powder ceases to be bioactive at these temperatures. Following some market research, the company approached L.B. Bohle to perform some milling tests.

L.B. Bohle's BTM 150 Turbo Mill produced the specified product size at a throughput rate of 375 kg/h in a closed container-to-container milling setup. For the test, the Bohle engineers chose a rotor speed of 6000 rpm on the hammer side.

The turbo mill used a 1-millimeter sieve insert, resulting in the same particle size as the ball mill. The BTM delivered the high-precision results that the manufacturer desired.

They initially bought one hammer mill but then requested two more. After installing the mills, the manufacturer dramatically improved its processing efficiency.

They can now mill numerous batches (e.g., 1000 kg batches) within one week rather than only one or two batches (using the traditional ball milling process) because the BTM can be disassembled and cleaned rapidly and almost without tools.

About L.B. Bohle Maschinen und Verfahren GmbH

L.B. Bohle with the headquarter in Germany, is one of the largest system suppliers for the pharmaceutical processing industry and related sectors. Internationally active, they focus on machinery and equipment as well as process technology and components.

In addition, L.B. Bohle offer sustainable solutions for demanding production processes in batch and continuous manufacturing for the oral solid dosage production. For instance, L.B. Bohle provides single or interlinked machines for the processes Weighing, Dry and Wet Granulation, Grinding and Sieving, Container Blending, Tablet Coating and Tablet Handling.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.