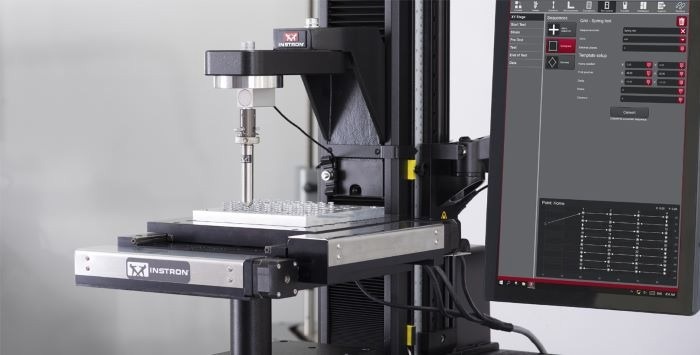

Instron's AT2 Automated XY Stage can be integrated with any current or new 6800 Series universal testing systems to automate tensile, compression, and flexure testing of single or multiple components with repeating test points.

Such systems are commonly used in the electronics and biomedical industries to test various components, devices, and materials.

Get in touch now

Image Credit: Instron - USA

In industries such as the medical device sector, some components, end products, or sub-assemblies have multiple elements, such as leads, that must be tested separately.

The Automated XY Stage System automatically repositions the specimen, allowing every element to be evaluated without having to reinstall the specimen.

Furthermore, when the first alignment is critical for successful testing, the XY Stage Testing System can produce speedy and consistent results in applications like insertion and withdrawal testing or precision bend testing. The Automated XY Stage’s adaptability allows it to evaluate various components, devices, and specimens.

Mini Keyboard Test Using AT2 Automated XY Stage

Video Credit: Instron - USA

Application range

- Biomedical: springs, pharmaceutical pills, vials, and syringes

- Type of loading: flex, tensile, compression

- Electronics: small electronics, touch-capable displays, keypads

Specifications

Source: Instron - USA

| . |

| Maximum Stage Load Capacity |

2 kN |

| XY Stage Travel (Option 1) |

300 x 150 mm |

| XY Stage Travel (Option 2) |

150 x 150 mm |

| Stage Speed |

25 mm/sec |

Automation advantages

Increased throughput

An automated testing system can test many specimens without requiring operator intervention. This reduces the sample's overall test time, allowing product creation and development data to be sent more quickly.

Image Credit: Instron - USA

Increased repeatability

Automated systems reduce operator influence on test results, allowing for more reliable and consistent outcomes. This is especially useful for firms with many operators working in different labs.

Better use of skilled labor

An automated testing system runs without operator supervision, producing results while expert operators increase productivity by focusing on additional significant tasks.

Improved safety and ergonomics

Automated testing reduces repetitive motion and physical engagement with the testing equipment, resulting in fewer operator injuries.

Image Credit: Instron - USA

Get in touch now

Bluehill® universal integration

Seamless control of the XY stage movements

XY stage movement

The Bluehill® Universal easily shifts the XY stage into several positions to configure specimens and identify test locations.

AT2 Automated XY Stage Movement in Bluehill® Universal Software

Video Credit: Instron - USA

Sequence builder

Bluehill® Universal allows users to create a succession of test locations using grid or diamond patterns or a unique sequence to test components with varying distances between them.

Building Sequences with the AT2 Automated XY Stage

Video Credit: Instron - USA

Example applications

Automated XY Stage for Button Testing

Button testing. Video Credit: Instron - USA

XY Stage for Compression Testing on Electronic Device Display Screen

Compression testing of electronic displays. Video Credit: Instron - USA

Get in touch now