Instron—USA offers 6800 Series universal testing systems, with capacities ranging from 500 N to 300 kN. These systems deliver exceptional performance while maintaining unrivaled reliability and accuracy.

The 6800 Series offers 0.5% accuracy down to 1/1000th of load cell capacity and up to 5 kHz data capture, giving it the utmost versatility for various testing needs.

Get in touch now

Instron 6800 Series Universal Testing Systems

Video Credit: Instron - USA

Available models—0.02 N (2 gf) to 300 kN force capacities

Low-force testing systems

The 6800 single column series has a capacity of up to 5 kN and is available in regular and additional height variants for low-force applications.

6800 Series single-column universal testing system. Image Credit: Instron - USA

Mid-range testing systems

The 6800 dual column table model series has a capacity of up to 50 kN and comes in regular and additional height options for higher-force applications.

6800 Series dual-column universal testing system. Image Credit: Instron - USA

High-force testing systems

The 6800 Series floor models provide up to 300 kN capacity available in standard, extra height/width, and tall base options.

6800 Series floor testing system. Image Credit: Instron - USA

Any application

The 6800 series Universal Testing Machines are specifically intended to perform tensile, flex, peel, compression, friction, shear, and pierce tests. These systems are compatible with hundreds of fixtures and grips from Instron’s vast accessory catalog, with specialized configurations tailored to perform the most typical tests in the automotive, consumer electronics, biomedical, and raw materials industries.

Image Credit: Instron - USA

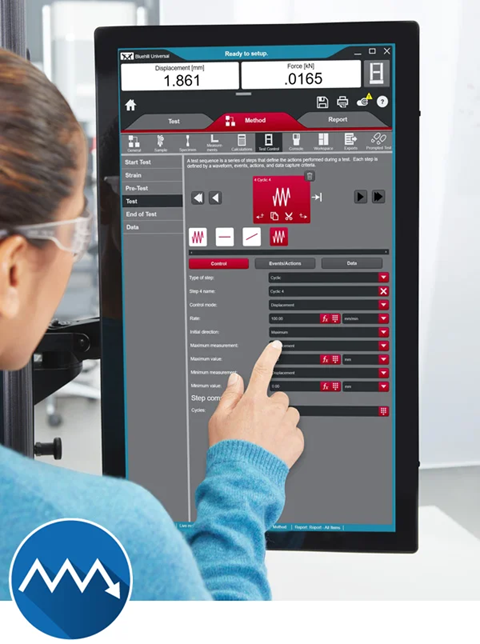

Bluehill® Universal. Image Credit: Instron - USA

Simpler—Powered by Bluehill® Universal

Instron’s Bluehill® Universal software powers the 6800 Series universal testing systems. Bluehill® Universal is designed with simple icons and workflows, making it easy to teach users and set up tests, allowing them to improve lab efficiency while eliminating costly errors.

QuickTest

When users require fast results, QuickTest allows them to run their test in seconds after entering a few basic parameters.

Pre-loaded templates

Numerous pre-configured techniques for some of the most widely used ISO, EN, and ASTM standards are available with Bluehill® Universal. All of these techniques come in modules tailored to the users' testing needs.

Workflow

With step-by-step guidance, users can be directed through the whole testing process, ensuring their tests stay straightforward, error-free, and repeatable. Additionally, users can easily add their text and images to the prompts.

Auto positioning

Auto positioning saves the precise fixture separation starting point for each test technique. This ensures that every operator performs each test in the same precise way during every shift and every day.

Auto positioning for the 6800 Series universal testing system. Image Credit: Instron - USA

TestProfiler

Triangle waves, holds, and ramps are examples of basic cyclic tests that can be created with TestProfiler’s assistance. Users can also create looping patterns with conditional logic to simulate real-world scenarios in tests.

TestProfiler in Bluehill Universal materials testing software. Image Credit: Instron - USA

Get in touch now

Smarter

Advanced Performance and Applications

The 6800 Series can include Digital Input/Output Channels and up to 11 Sensor Conditioning Modules, ensuring compatibility with novel accessories and external devices. Users will be able to collect synchronized data at up to 5 kHz while testing on a 6800 Series frame and modify the bandwidth to ensure that no test event is missed.

Image Credit: Instron - USA

Operator protect. Image Credit: Instron - USA

Safer—Safety without sacrificing throughput

Operator protect

The 6800 Series is built around Instron’s patent-pending Operator Protect architecture. A smart workflow monitors system status from setup to test completion to keep operators and equipment safe.

Built-in safety coaching

The 6800 series will provide users with continual, clear visual feedback on system conditions. Users will be able to easily understand when the system is in a safe configuration mode, and they will be prompted to quit the test environment once these safety constraints are lifted.

Smart-close air kit

Lower grip-closing pressure and controlled speed during the test set-up phase reduce the risk of finger pinching from pneumatic grips.

All-new handset

The 6800 handset’s innovative ergonomic design, which is directly mounted to the frame, aims to bring system controls closer than ever before. Operators can use this handset, both mounted and unmounted from its dock.

6800 Series handset. Image Credit: Instron - USA

Customizable soft keys

The operator can initiate a variety of commands with two user-defined “Soft Key” buttons. By defining the soft keys for each technique, each test can be tailored.

Virtual interlock

Instron’s patent-pending system architecture inhibits machine movement, preventing the crosshead from moving unintentionally.

Variable speed jog

When the system is in set-up mode, it will default to a safe speed that allows the operator to work comfortably in the test space.

Precise positioning

The Fine Position adjustment thumbwheel with tactile feedback enables precise crosshead positioning in 4 μm increments for sensitive testing.

Specimen Protect

Specimen Protect automatically adjusts the crosshead to prevent inappropriate forces from being applied to the specimen, protecting the valuable specimen from harm.

6800 Series dual-column testing system. Image Credit: Instron - USA

Built to last—Protecting user’s investment

Collision mitigation

Reduces the risk of damaging fragile specimens and equipment by stopping the crosshead if force is detected during jogging or returning.

Load cell overload protection

The 6800 series can automatically stop when the load cell reaches maximum capacity, preventing harm to the system, load cell, and accessories.

2580 series load cells

The 2580 Series load cells, developed for use with 6800 testing equipment, provide exceptional performance. They measure forces as low as 1/1000th of the force capacity with a precision of ±0.5% of reading.

Instron’s load cells can withstand loads up to 150% of their force capacity without suffering damage and 300% without experiencing mechanical failure. Electrical calibration and automatic transducer recognition make them easy to utilize.

Built for durability

Stiff frames for high-strength materials

The 6800 is specifically designed to deliver exceptional performance. To ensure longevity and excellent performance, it has pre-loaded bearings, precise ball screws, a sturdy crosshead and base beam, and low-stretch drive belts.

6800 Series dual-column internal components. Image Credit: Instron - USA

Precision guidance for alignment and bending

When conducting a uniaxial test, precise stress and strain findings can only be produced with a system that includes strong, precise guidance columns that ensure minimal specimen bending under load.

Larger motors for better reliability

The 6800 load frames feature powerful motors with reserve capacity, allowing faster acceleration. Maintenance-free brushless AC servomotors can be tested for creep, cyclic, and relaxation for up to 10 days (up to 1 Hz at 25 °C).

Servo-controlled drive system

The 6800 drive systems have strong steel casting, a dual-belt drive system, and a powerful motor. The dual-belt systems eliminate crosshead tilt and support system alignment by providing synchronous movements of the ball screws, unlike those that use gear-reducers, which cause backlash and lower drive system rigidity.

Instron® 68FM Universal Testing Systems | Advanced Performance for High-Force Testing

Video Credit: Instron - USA

Get in touch now