In this interview, AZoNetwork speaks to Knauer about the use of FPLC for purification of proteins and how their products enable scientists to get the most of liquid chromatography; conducted by Matthew Rafferty.

Could You Give me a Brief Overview of FPLC?

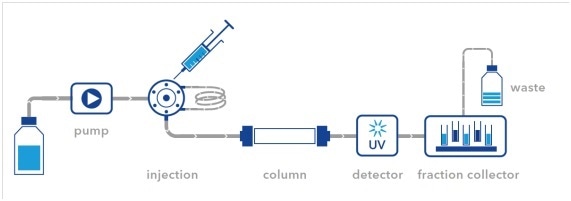

FPLC stands for Fast Protein Liquid Chromatography which is a technique used to purify biomolecules e.g. proteins. The general system set up is similar to preparative HPLC for small molecules and generally consists of an eluent pump, a sample injector, a column which facilitates the actual purification, followed by detectors. In classical HPLC, UV/VIS is the most common technique to detect a signal. In FPLC a UV detector is additionally combined with detectors for conductivity and pH to monitor not only the sample eluted but also the buffers used. Usually the goal of FPLC is to collect the separated biomolecules in fractions. This can be conducted manually but is mostly automated by a fraction collector.

Figure 1: Simplified Set Up of an FPLC

How is it Different from HPLC?

The main difference can be found already in the name. Whereas High Pressure Liquid Chromatography (HPLC) is carried out at high pressure of up to 1200 bar in UHPLC systems, FPLC is mostly carried out at low pressure below 30 bar. This is due to the fragility of biomolecules as well as the column matrices which are used and are only stable at low pressure.

Another major difference are the solvents used in FPLC. For purification of proteins, one uses saline buffers to prevent denaturation of the biomolecules. Organic solvents used in classical HPLC would destroy the native structure of proteins. When applying saline buffers, it is crucial not to use stainless steel as mainly utilized in HPLC systems, because corrosion could occur. Another big difference is that FPLC is often performed at 4°C to prevent denaturation of the target molecules. All these parameters have to be taken into account when designing an FPLC system.

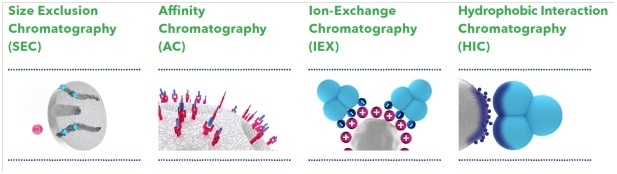

Figure 2: Main methods used in FPLC.

What Types of Purification Can You Use With FPLC?

The purification method is defined by the column applied with the system. In FPLC the main four methods are Size Exclusion Chromatography (SEC), Affinity Chromatography (AC), Ion Exchange Chromatography (IEX), and Hydrophobic Interaction Chromatography (HIC).

Size Exclusion Chromatography is the separation of biomolecules according to their size. The SEC column media consists of porous beads. Smaller molecules can diffuse into these pores and are retained longer by the media, while larger biomolecules are almost not interacting and therefore elute first.

Making use of a specific affinity of the protein towards the column media for purification purposes is called Affinity Chromatography. The specific binding of the target molecule on the column media allows to run a protocol consisting of three phases: loading, washing, and elution. During this procedure, molecules with the specific binding properties toward the column media are separated from all other contaminants.

In Ion-Exchange Chromatography on the other hand biomolecules are separated according to their charge at a specific pH and in Hydrophobic Interaction Chromatography according to their hydrophobicity.

What Do KNAUER Offer for FPLC?

The guiding principles of the KNAUER FPLC portfolio are robustness, flexibility, upgradability on a minimum footprint made in Germany. AZURA FPLC is biocompatible (metal free) and can be operated in the cold room. Multiple functionalities such as automatic sample injection via autosampler, column switching, buffer and sample selection, as well as fraction collection enable the user to automate the purification process. A large range of different detectors make the target molecules visible. Different flow rates and compatibility to columns from all venders offer maximum flexibility.

The customer does not have to fear ending up in a dead-end when buying a specific system. Instead they will be able to flexibly change or upgrade the system according to their needs with simple and single components like an additional pump or a switching valve.

Especially valves are an underestimated component in a chromatographic system. However, if you think about it, a valve at the right position can have a massive effect, e.g. by helping to automate your purification process or enabling optional purification steps through reverse flow mode to rinse the column more effectively.

Figure 3: Flexible System Sizes

In October 2018 we have added prepacked FPLC columns to our portfolio which are the perfect fit to our AZURA Bio purification systems. We offer the Sepapure columns and bulk material for affinity, ion-exchange, and size-exclusion chromatography based on agarose and dextran media. The prepacked FPLC columns are available as 1 ml and 5 ml cartridges compatible with standard 10 – 32 UFN PEEK connections. All AC columns are consisting of ligands immobilized on 100 µm agarose particles with Antibody binding capacities of <15 mg/ml (ProteinG), <30 mg/ml (Protein A) and tagged Protein binding capacities of <40 mg/ml (His-Tag) and <10 mg/ml (GST-Tag). IEX columns are also based on 100 µm agarose beads with charged ligands and ion capacities of <0.12 mmol/ml.

All in all, we are proud to be able to offer our customers the full package: an optimized solution from the application to the hard- and software.

How Does This System Help Your Customers to Attain Their Goals?

By freely combining devices and valves the customer can tailor their system completely according to the application without having to compromise. KNAUER is always happy to configure the perfect solution to specific purification tasks. Also, AZURA Bio purification systems can be expanded easily, thereby the system can grow with the tasks it encounters.

Do You Offer Special Software for Biopurification?

We offer a highly versatile FPLC Software called PurityChrom, which is perfect for the application in the biopurification area, because it is a volume-based chromatography software. The software comes with a functional individually adjustable visualization of the system, allowing an intuitive manual operation of the FPLC even with complex configurations. Due to the highly flexible FPLC setup together with PurityChrom our customers can write methods for complex methods and gives the user total control over the purification.

Where Can Our Readers Go to Find Out More?

You can find a lot of information on our webpage https://www.knauer.net/en/Systems-Solutions/FPLC along with our FPLC brochure and many Applications we ran in our lab with the KNAUER FPLC Systems.

Maria studied Chemistry at the Free University in Berlin and continued her PhD in the area of Chemical Biology at the Leibniz-Institut for Molecular Pharmacology (FMP) in Berlin. She joined KNAUER in 2018 as Product Manager for FPLC.

About KNAUER

KNAUER is an owner-managed middle-sized company with more than 120 employees situated in Berlin, Germany. Since 1962, KNAUER has been producing and developing high performance liquid chromatography (HPLC) systems.

KNAUER is an owner-managed middle-sized company with more than 120 employees situated in Berlin, Germany. Since 1962, KNAUER has been producing and developing high performance liquid chromatography (HPLC) systems.

The HPLC technique is used to separate, identify and quantify substances in a mixture. It can be used for many applications, including the analysis of toxics in drinking water, the detection of drugs in blood as well as for the purification or quality inspection of pharmaceutical and chemical products.