Sponsored Content by SepmagReviewed by Maria OsipovaMay 9 2024

For a consistent magnetic bead separation process, it is crucial that all magnetic beads are subjected to identical conditions. The key to maintaining this consistency, especially during scaling up, lies in the control of magnetic force.

Image Credit: Sepmag

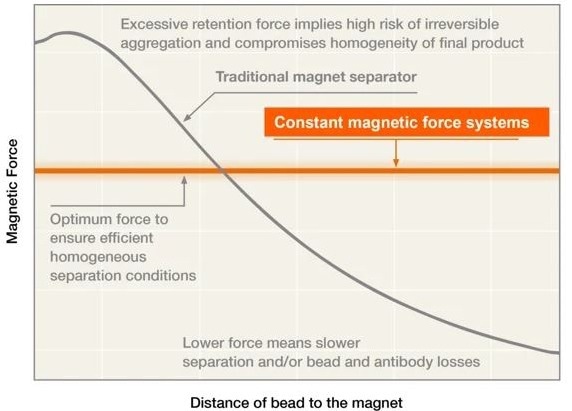

Traditional magnetic separators, however, present a challenge: they generate a magnetic force that is very high near the side of the vessel closest to the magnet and decreases rapidly with distance. Consequently, beads in the retention area experience the greatest magnetic force, while those farthest from the magnet experience the least.

The difference in magnetic force might seem negligible at small volumes, but as the volume increases, the relative difference in magnetic force between the retention area and the far side of the vessel becomes more significant.

Consequently, magnetic beads at the farthest point move slower due to the reduced magnetic force, while beads closer to the magnet tend to aggregate more quickly as the vessel diameter increases.

To solve this problem, the magnetic force must be kept constant across the entire working volume. In simple terms, the magnetic force should be increased for the farthest beads but not for those closest to the magnet. A novel method is needed to achieve this task.

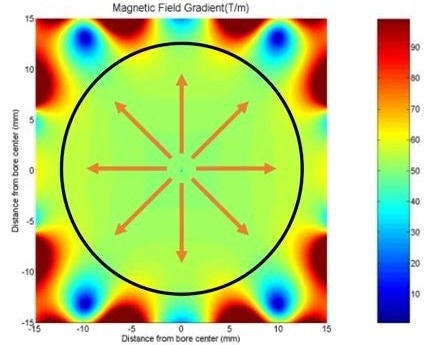

Constant magnetic force separation systems, such as Sepmag, produce a magnetic field pattern using a high magnetic force and gradient. This is done by employing arrays of permanent magnets, which generate a constant magnetic force across the entire working volume.

When the magnetic force is constant and radial, the beads farthest from the magnet are located at the center of the vessel, which is significantly closer than in traditional separators, where the force diminishes with distance. This reduced distance, coupled with a larger, more uniform magnetic force, leads to a much shorter separation time for the same volume.

Figure 6.1. Map of the radial constant magnetic force inside an advanced magnetic bead separation system. The color indicates the intensity of the magnetic force, the arrow shows its direction. Image Credit: Sepmag

Furthermore, the radial direction of the force evenly distributes the magnetic beads along the cylindrical walls of the vessel, effectively enlarging the retention area and consequently lowering bead density. With a constant magnetic force enabling very short separation times, the magnitude of the force can be reduced when there's a risk of bead aggregation.

By minimizing both the retention force and the density of beads in the retention area, the likelihood of clump formation is significantly reduced.

Constant magnetic force systems provide the flexibility to customize a force value for different applications. This enables users to select the optimal magnetic force for each magnetic bead suspension.

For instance, when coating magnetic beads to create an IVD test, if the chemistry makes the beads more prone to aggregation, a low constant magnetic force must be used to prevent clump formation. In contrast, when employing a very low concentration of nanoparticles for cell separation, the highest possible magnetic force must be used.

This constant magnetic force approach guarantees consistency within each batch, as all beads experience the same force. It also enhances batch-to-batch reproducibility. In contrast, with classical separators, even a minor difference in vessel placement between batches can dramatically affect both the separation time and the likelihood of bead aggregation.

A well-defined magnetic force facilitates the testing of devices with varying force values. This allows users to select the optimal intensity tailored to a specific application, magnetic bead suspension, and matrix. Additionally, when using permanent magnets, the specified magnetic force value is inherently constant.

Figure 6.2. Showing the relationship between the distance of bead to the magnet and the magnetic force, in constant magnetic force systems (orange) and traditional magnet separators (gray). Magnetic force in traditional separators is highest where the bead is closest to the magnet and declines with distance from the magnet. In constant force systems there is no change in magnetic force with the distance of a bead to the magnet. Magnetic force is also lower closest to the magnet in constant force systems than traditional magnetic separators, which reduces the risk of irreversible aggregation. Image Credit: Sepmag

About Sepmag

Sepmag develops smart and scalable magnetic bead separation equipment for the international diagnostics market and for any user of magnetic bead separation techniques.

Sepmag's innovative Smart & Scalable Magnetic Bead Separators are designed to deliver unparalleled control and efficiency across all volumes, preventing bead aggregation, minimizing material loss, monitoring and keeping records for Quality Control purposes, and maximizing safety.

These benefits are applicable through a range of laboratory settings from R&D facilities to large scale production processes. Sepmag is based in Barcelona and sells in North America, Europe and Asia.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.