Sponsored Content by SepmagReviewed by Maria OsipovaMay 9 2024

Magnetic separation has become increasingly popular in biomedical science and industry. This technology uses magnetic properties of micro/nano-sized particles to separate macromolecules of interest, such as nucleic acids, proteins, and peptides, from biological samples or chemical suspensions.

Image Credit: Sepmag

Magnetic materials, commonly referred to as ferro- or ferromagnetic, exhibit a significant response to magnetic forces, enabling interaction over a distance. All these materials have memory in their standard form, meaning they remain magnetized even when the applied magnetic force is removed.

One method for enhancing memory retention is by reducing the size of the particles (like in the old cassette tape of computer floppy discs) to a certain diameter. However, if it is decreased well below this threshold, it completely loses the magnetic memory.

This state, characterized by a high response to an applied magnetic force and zero magnetization when the force is removed, is known as superparamagnetism. It is crucial in the design and synthesis of magnetic beads or particles, as well as in the development of magnetic separation systems.

In recent decades, the rapid advancement of biomedical science has led to the development of several separation/purification methods of macromolecules and the introduction of magnetic beads/particles with improved properties.

These advancements have created a need for more efficient magnetic separation technologies to satisfy the demands and replace traditional non-magnetic filtration, centrifugation, and separation approaches.

Surface-coated magnetic beads/particles with specific affinity ligands can bind to biomolecules of interest, such as antigens, antibodies, catalyzers, proteins, or nucleic acids. Following the incubation phase, the vessel is then exposed to a magnetic separation rack.

The magnetic beads/particles (along with the attached biomolecules) are attracted and held in place by the externally applied magnetic force.

Following the separation phase, the supernatant, which is not affected by the magnetic force, can be discarded. The biomolecule, which is bound to the magnetic beads, can then be effortlessly isolated from the original media and eluted if needed.

Magnetic separation is the most practical approach for recovering small particles with a diameter of 0.05–1 μm, even in the presence of biological debris and other similar-sized materials. In addition, magnetic separation is highly efficient and particularly well-suited for large-scale purifications.

Commercial magnetic separation racks serve as a foundation for various automated low- to high-throughput procedures, offering time and cost savings. They are less demanding, eliminating the need for centrifugation, minimizing cross-contamination, and operating with a range of magnetic beads/particles in both manual and automated modes.

Magnetic beads and magnetic separation rack interaction

Before commencing the separation process, it is essential to choose the most suitable separation strategy. This involves considering the system and the process while also considering all relevant parameters: target, separator design, beads adsorbents, process, and conditions.

The effectiveness of the separation strategy relies on the specific characteristics of the target molecule, including both the actual magnetic separation process and the interaction between the magnetic material and the target molecules.

There is a wealth of research in literature on magnetic beads/particles and how their respective characteristics (such as density, diameter, magnetic pigment content, and surface activation) impact the efficiency of the process they are involved in.

This strong focus on magnetic beads and particles has often overshadowed the importance of magnetic separation racks, leading to significant problems. These issues include high losses, slow separation, inconsistent results, and clump formation, resulting in wasted materials, increased costs, and wasted time. Consequently, this can yield unreliable results that are difficult to cite in research.

Hence, it is vital to consider the magnetic bead separation process as important as magnetic beads/particles.

Magnetic carriers need to interact with a magnetic force in order to move. The magnetic field must generate a magnetic force, which is enough to overcome the drag force generated by buffer viscosity. If the magnetic separation rack does not generate the appropriate magnetic force, which is different to the magnetic field intensity, the entire process becomes inefficient, regardless of the characteristics of the magnetic beads.

Despite the importance of the subject, detailed technical literature describing how magnetic force interact with beads is very thin on the ground.

Magnetic separation racks and systems

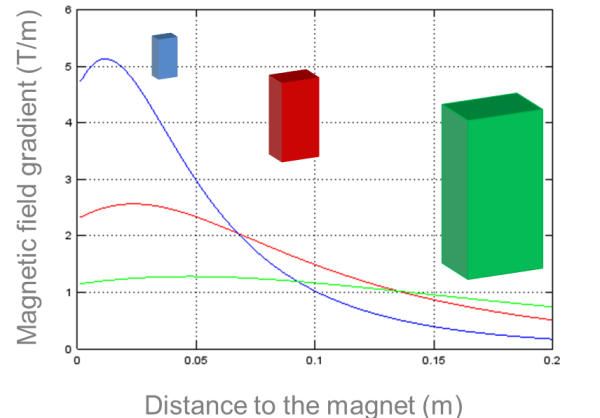

A basic magnetic separation rack is a simple permanent magnet device. Calculating the value of a magnetic force at each point in space and then determining the gradient is quite straightforward. The graph below displays the results as we move away from the center region of the magnet’s surface.

In the best-case scenario (assuming the magnetic beads are always saturated), the magnetic force changes very quickly according to the distance from the surface.

When comparing different magnet sizes, it may be surprising to find that smaller magnets generate strong forces near the surface compared to larger ones. This is because larger magnets have a more constant magnetic field, which does not generate force.

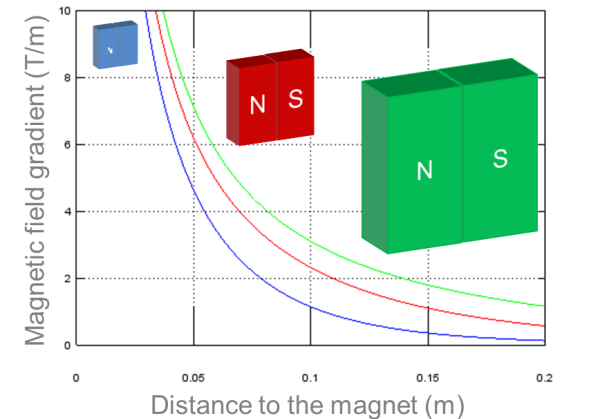

Some magnetic separation devices attempt to circumvent this issue by using two permanent magnets with opposite polarity.

This means that the field varies near the center of the assembly and that there are stronger forces near the surface of the permanent magnet where we want the magnetic beads to be located at the end of the process.

Image Credit: Sepmag

The magnetic force generated, however, is extremely uneven, with its intensity rapidly changing with distance. Consequently, the force exerted on the beads closer to the magnet is very strong, while the force on the beads further away from the magnet’s surface is very weak.

Image Credit: Sepmag

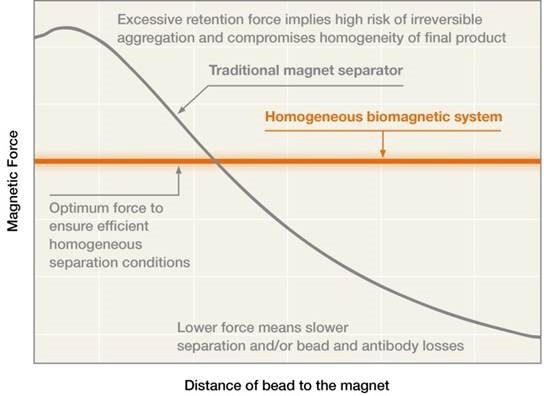

There are two practical drawbacks associated with this force profile in the magnetic bead separation process:

- Very long separation time (or high sample losses): Due to the weak force acting on the beads furthest away, the process of recovering all the magnetic beads and their attached biomolecules can be quite time-consuming. In vessels larger than a few milliliters, this can take several hours. The process could be stopped sooner, but doing so would result in significant losses.

- High risk of irreversible aggregation: Nearest to the magnet, beads experience stronger forces and move rapidly toward the retention area. Upon arrival, these forces intensify, causing the beads to accumulate and form clumps. Conversely, beads farther from the magnet separate more slowly, leading to acceptable losses. However, beads that quickly reach their destination endure extremely high forces for prolonged periods, complicating the process.

Image Credit: Sepmag

Solving aggregation and distant bead loss

To streamline the process, it is necessary to modify the magnetic separation rack to solve both problems simultaneously. Increasing the force, such as using larger assemblies of magnet pieces, reduces the loss of the farthest beads. However, there is a significant increase in irreversible bead aggregation near the magnet’s surface.

On the other hand, decreasing the magnetic force in the retention region alleviates the irreversible aggregation issue but notably increases the loss of magnetic beads and their attached biomolecules.

To address both issues at once, more force must be exerted on the farthest beads while decreasing the force in the retention region.

Finding a solution with a magnetic force profile that varies with distance, like in classical magnetic separation racks, can be quite challenging.

An optimal solution would involve a magnetic force that remains constant with distance. When the force is homogenous (like with Sepmag’s Magnetic Beat Separation Systems), it is feasible to obtain a stronger magnetic force away from the retention region and a weaker force near the magnet at the same time.

This method ensures that beads, even those furthest from the magnet, travel quickly, thus accelerating the overall Magnetic Bead Separation Process without additional losses.

The beads reach the retention area at a constant pace because all the beads move at the same speed and are subject to a gentle force – just strong enough to retain them when the supernatant is extracted. What is more, no clumps are formed, and sonication is prevented, greatly simplifying the scaling-up process.

Homogenous magnetic force

Image Credit: Sepmag

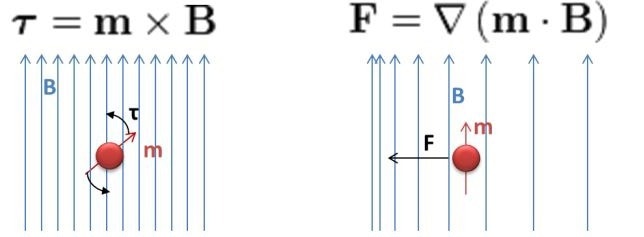

The simple and oft-forgotten notion is that homogenous magnetic force generate magnetic torque but not magnetic force.

When beads are separated with a simple neodymium-iron-boron magnet, it is not solely due to the strong magnetic force it generates. Rather, it is primarily because of the significant change in the magnetic force and distance. An inhomogeneous magnetic field is needed to produce a magnetic force.

Image Credit: Sepmag

Another crucial concept to consider is that the strength of the magnetic force acting on a bead is influenced by both its magnetic moment and the magnetic force profile. The magnetic moment of the bead depends on the magnetization curve.

For superparamagnetic materials, when the magnetic force is very low, the magnetic moment is proportional to the intensity of the applied magnetic force (constant susceptibility). When the force applied is high enough, the magnetic properties become saturated and the bead magnetic moment is constant.

The exact ‘saturation field’ value depends on the specific material used for the ‘magnetic pigment’, but for a typical nanosized iron oxide used on commercial beads, the applied magnetic force should be over B>0.1 Tesla (80 kA/m).

Magnetic separation rack vs. constant magnetic force separation systems

The video clearly illustrates the distinction between a magnetic separation rack (positioned on the right) and a constant magnetic force separation system (situated on the left). Despite employing the same quantity of permanent magnets, the separation time is significantly reduced in the latter system, all while maintaining a gentler treatment of the beads to prevent clumping throughout the process.

Homogenous vs inhomogenous magnetic bead separarion

Video Credit: Sepmag

The exact value of the force is influenced by factors such as magnetic gradient, magnetic moment of the beads, and buffer viscosity. As a result, there is no universally recommended magnetic force gradient value.

Fortunately, the companies specializing in advanced magnetic beads separation systems have a wealth of experience in the field and can assist you in determining the final value.

The choice of the right gradient is crucial as using a value that is too low would make it impossible to separate small beads or beads in highly viscous suspensions, like whole blood.

On the other hand, an excessively high magnetic force gradient can hinder the effectiveness of large beads in water-based suspensions. This is because the resultant magnetic force would be excessive and form clumps.

For most life science processes, finding a single system that works for all magnetic bead separation processes is not feasible.

When devices with different magnetic forces at each point of the working volume are used, it becomes challenging to validate separation processes. Since the magnetic separation conditions vary for each bead, it is hard to parameterize the process and determine the critical values of an effective setup.

By using a constant magnetic force, it becomes possible to evaluate the process in familiar conditions for the entire suspension. This allows for the examination of different magnetic forces as needed and the identification of the optimal value for the magnetic bead separation process.

SEPMAG® magnetic separation racks

There are a wide range of magnetic separators available on the market, ranging from basic concentrators for single tubes to advanced automated devices.

Particles larger than 1 micrometer can be easily separated with simple magnetic separators, while smaller particles (magnetic colloids with a particle size from 10 to hundreds of nanometers) may require the use of high-gradient magnetic separators.

The racks are specifically made to accommodate different quantities of micro-tubes or tubes, depending on the sample volume. Test tube magnetic separators are capable of separating magnetic particles from volumes between approximately 5 microliters and 50 milliliters.

SEPMAG® offers 2 types of magnetic separation racks:

- Small volumes (Sepmag LAB, Sepmag A): For sample volumes ranging from 1-400 ml

- Large volumes (Sepmag Q, Sepmag N): For batches of several liters

The MONITOR hardware and software, along with the QUALITANCE system, allow operators to monitor the entire magnetic separation process by recording and tracking various processes.

An R&D-oriented setup is used to analyze the impact of various factors on magnetic separation behavior, such as changes in suspension components (bead type, concentration, buffer composition, temperature). This allows the development of processes that can be easily scaled up (or down) to different volumes while using the same magnetic force.

The QUALITANCE setup is designed for Production Quality Assurance. It enables the comparison of the separation of the current batch with the reference separation curves, facilitating the early detection of issues related to bead size, distribution, concentration, or buffer conditions.

This allows for immediate corrective actions to be taken, eliminating the need to wait for QC assessments that can take hours, days, or even weeks.

About Sepmag

Sepmag develops smart and scalable magnetic bead separation equipment for the international diagnostics market and for any user of magnetic bead separation techniques.

Sepmag's innovative Smart & Scalable Magnetic Bead Separators are designed to deliver unparalleled control and efficiency across all volumes, preventing bead aggregation, minimizing material loss, monitoring and keeping records for Quality Control purposes, and maximizing safety.

These benefits are applicable through a range of laboratory settings from R&D facilities to large scale production processes. Sepmag is based in Barcelona and sells in North America, Europe and Asia.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.