Sponsored Content by SepmagReviewed by Maria OsipovaMay 9 2024

When initially developing magnetic beat particle kits, R&D companies experiment with small volumes using a magnetic separation rack to optimize various factors. Once the kit proves successful, the company will attempt to bring it to market, increasing production in the process.

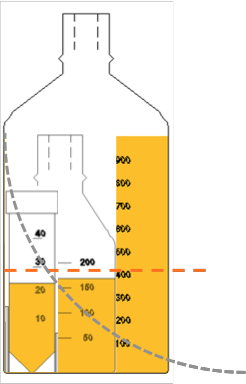

Image Credit: Sepmag

Using just a few hundred milliliters of material, a company can produce several kits. However, as demand rises, the in vitro diagnostic (IVD) company must be capable of continual expansion to meet that demand. If the process cannot be scaled up, the magnetic beat separation process becomes the limiting factor for the company’s growth.

This article focuses on magnetic bead separation with a magnetic separation rack and how to scale up this process. For those wishing to learn more about this topic, The Basic Guide to Scale-up magnetic bead Separation Processes is a freely available eBook offering a more comprehensive explanation.

During periods of slow market growth, the company may consider simply duplicating the number of lots. However, managing separate small lots can be challenging because the company must ensure consistency across them. Each lot requires individual quality control and characterization efforts.

Pursuing this kind of production as demand increases can become prohibitively expensive for the company, especially in terms of resources needed for coating, resuspension, and quality control.

Advantages of increasing the lot volume

Expanding lot volume in response to increased demand offers significant advantages for companies, enabling them to:

- Reduce the number of essential quality control checks, as only one check is necessary for the large volume lot before it is divided into kits.

- Lower labor costs, as the time required to produce a large volume of material is only marginally longer or equivalent to that needed for a small volume.

- Conveniently trace kit issues to a specific lot since many kits originate from the same batch.

- Benefit from the economies of scale.

However, a word of caution: All the benefits of scaling up the production of magnetic bead separation processes can be lost if the process conditions are not well-defined.

Therefore, it is advantageous for companies to increase production as soon as they feel the market demands more supply of the product. This scale-up process must be executed carefully to ensure that large lots are not only internally consistent but also as consistent as possible with each other.

Acknowledgments

Produced from materials originally authored by Lluis M. Martínez from SEPMAG.

About Sepmag

Sepmag develops smart and scalable magnetic bead separation equipment for the international diagnostics market and for any user of magnetic bead separation techniques.

Sepmag's innovative Smart & Scalable Magnetic Bead Separators are designed to deliver unparalleled control and efficiency across all volumes, preventing bead aggregation, minimizing material loss, monitoring and keeping records for Quality Control purposes, and maximizing safety.

These benefits are applicable through a range of laboratory settings from R&D facilities to large scale production processes. Sepmag is based in Barcelona and sells in North America, Europe and Asia.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.