Sponsored Content by PolytecJan 14 2020

In biomechanics, non-contact laser Doppler vibrometry is a highly important and potent tool. In determining the dynamic properties of a pelvic bone, recent experiments have relied on deflection measurements from a 3D scanning laser vibrometer, whereby exceptional results were attained, even with objects that are geometrically intricate and complex.

Introduction

To investigate and model components for medical applications in biomechanics, finite element methods (FEM) have been utilized. Assisting with procedures such as bone surgery, various approaches generate and evaluate realistic bone models from computer tomography (CT) data. Verification and resulting model quality depends on the measurement method and technology. Engineers customarily use experimental modal analysis when studying vibration characteristics of mechanical components and such deflection measurements are used for the reference and verification of simulation models, as are needed in experimentation here.

Biological materials demand the focus in biomechanics rather than engineering sciences due to the complex modifications that endure with extracted biological material such as drying out and decomposition. Because of this, there is only a short period of time to make a relevant measurement. For this reason, an optimized measurement method is required that guarantees the inspection of fresh preparations.

Test Setup

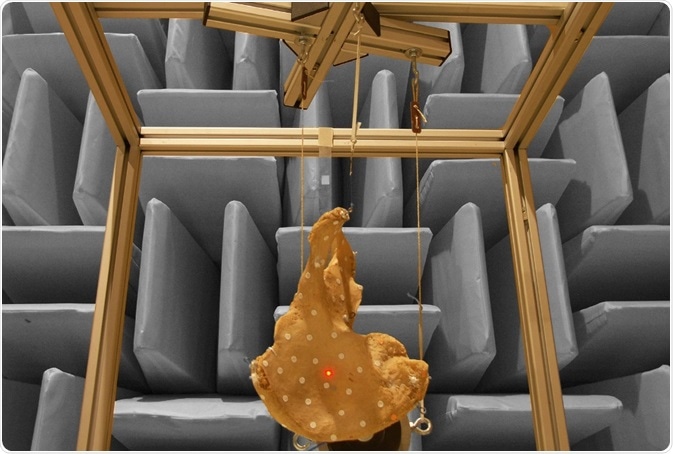

Preliminary testing on a treated pelvic bone that develops an optimized measurement process occurred. Initially, a suitable suspension device was fabricated for the bone to be examined and attention had to be paid to the experiments being carried out in “free suspension”. The bone is suspended in a test frame so that the resonant frequencies of the rigid body suspended by the ropes are less than 10 Hz with rubber ropes. Conversely, above 100 Hz, the object under investigation can be seen as freely mounted. The vibration-isolated suspension and non-reactive connection of the electrodynamic shaker to the object also need to be delicately carried out.

Calibration and Measurement

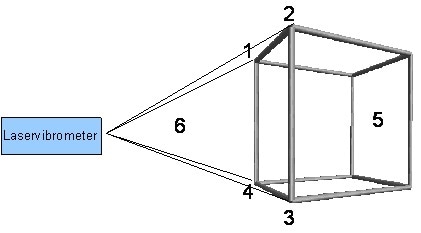

PSV- 400-3D, a 3D scanning laser vibrometer (new PSV-500-3D verson now available), measures the hip bone vibration response (see Figures 1 and 2). When aligning scanning heads with each other, which are oriented at three known angles, the measured points should allow the largest possible volume to be spanned and the vibration response can be measured simultaneously in all three spatial directions (X, Y and Z) time. Distribution of the measurement points across the depth of the object generates the most superlative results.

Figure 1: Suspension of the hip bone on rubber bands (red spot: focus point of the laser beam).

Figure 2: Test setup with a 3D scanning laser vibrometer.

Six alignment points are defined in figure 3. Defining the measurement grid and coordinate measurement system, carrying out a geometry scan and assigning the focus values ensure the precise measurements of objects in the test frame. For the bones being studied, the coordinate system of the FE model is used for measurement. Prior to the CT scan, markers are stuck to certain points on the bone as alignment points, allowing the precise transmission of the individual measurement point position to the FE model.

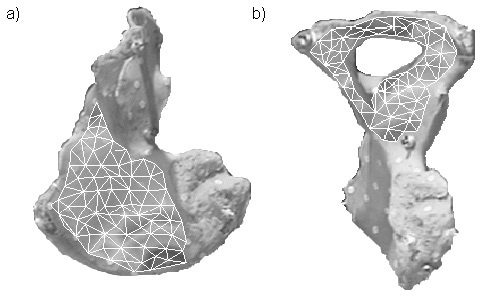

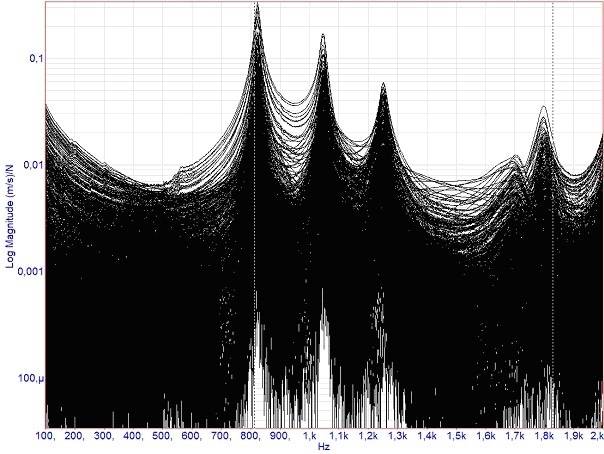

The force introduced into the structure at the coupling point and the simultaneous response (vibrational velocity) at the defined measurement point were measured using a vibration exciter or shaker to continuously excite the bone. Shedding light on the bone area with the greatest displacement and to establish the ideal measurement points, the results of the FEM modal analysis are used as a first approximation. Five resonances were seen when two areas of the preserved bone and the transmission functions were measured (Figure 5) and superimposed onto each other in Figure 4.

Figure 3: Position of the alignment points on the test frame.

Figure 4: Measurement areas of the treated bone studied: a.) Measurement grid 1, b.) Measurement grid 2.

Figure 5: Superimposed view of the measured transmission functions.

Conclusions and Outlook

Both the test method and the measurement process were optimized to reduce time and effort to help align the numerical models with real experimental results. Based on previous studies, five-mode shapes in the frequency range from 100 Hz to 2000 Hz fulfill the necessary condition of keeping biological samples fresh and close to their in-situ dynamic characteristics.

Measurements using the 3D laser vibrometer represent a significant improvement in the dynamic analysis and modeling of human pelvic bones in comparison to previous methods. In its inaugural use to determine the modal parameters of a pelvic bone, the 3D scanning laser vibrometer allows the accurate measurement of the spatial vibration modes that previously has not been accessible.

About Polytec

For over 50 years Polytec has provided high-technology, laser-based measurement solutions to researchers and engineers. Our commitment is to provide the most precise and reliable optical instruments and sensors available for non-contact measurement, setting Polytec apart from the competition as the gold standard in the design and manufacture of vibrometer and velocimeter systems. Our innovations answer many pressing manufacturing and engineering challenges.

Polytec was founded in 1967 to distribute commercial laser technology to industrial and research markets. Building on the company’s early success, Polytec began to develop and manufacture innovative laser-based test and measurement instruments in the 1970’s. These products have become known around the world as the gold standard in non-contact, laser-based measurement of vibration, speed and length.

Advanced product development remains a core strategic activity at Polytec with new electro-optical systems being designed for applications such as analytical process measurement, noise analysis, and factory automation.

In addition, Polytec continues to develop its key business structure through critical technology acquisitions and focused spin-offs. Some of the most recent highlights include:

In 2005, Polytec PT GmbH Polymere Technologien was founded as a spin-off, with over 30 years of know how in the supply and application of high tech adhesives and silicones in demanding electronic, optical and medical industries.

In 2008, LATAB was acquired and became a member of the Polytec organization. LATAB's early entry into the LED illumination market has produced the broadest and most flexible product mix for technical applications.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.