Sponsored Content by PolytecJan 14 2020

State-of-the-art laser-Doppler vibrometry reveals the vibrational and dynamic characteristics of hearing mechanics. This technology provides ease of use and unrivaled accuracy and resolution. Laser vibrometers open new ways to understanding hearing mechanics for those studying one of the most sophisticated sound and vibration amplification systems: the human ear. Laser vibrometry is quite indispensable to those actively involved in design, quality control, development, calibration and certification of middle ear implants.

Point, Shoot, Measure

Laser vibrometers consist of a low-power laser beam, picking up the signature of a vibrating object and transferring it into an output proportional to velocity and displacement that the researcher can easily interpret. The manual or automated positioning of the laser beam is done through interactive video imagery. Vibrometers are used for non-contact vibration measurement and the laser beam’s micron-sized footprint can easily be accommodated in small structures, including inner ear structures.

Unveiling Minute Vibrations

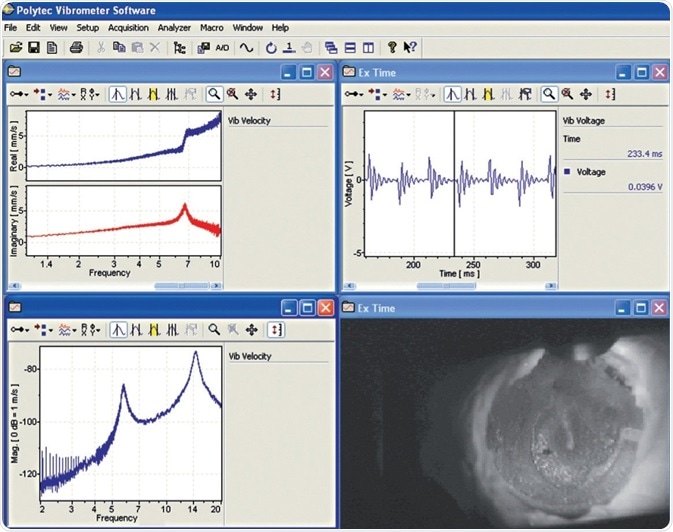

The smallest and most subtle vibration patterns can be sensed by laser vibrometry and are displayed in a variety of formats; from time and frequency domain signals to whole full-field 2D or 3D data with full animations. That data display shows how mechanical conduction occurs. Scanning vibrometry delivers a whole picture of frequency responses or full-field structural deflection shapes.

A Wide Range of R&D Applications

Dynamic measurements of temporal bones, hearing aids, ear models, cochlear structures, middle ear prostheses, implants and devices are obtained via laser-Doppler vibrometry (LDV). Through the last 30 years these findings are well documented in literature by the hearing research community.

Assessments of pre- and post- prosthetic LDV (TORPs, PORPs and implantable middle ear hearing devices) provide a better understanding of prosthesis function and performance. Other examples include the assesment and performance measurements of the tympanic membrane, ossicular chain function (stapes footplate) and other studies.

There is ample sientific literature dealing with dynamic middle ear performance (air conduction, bone conduction, air-bone gap, tympanometry, etc.) studies. LDV methods and Scanning Vibrometry have been key technologies towards expanding the understanding of the inner ear's organ of Corti dynamics (basilar and tectorial membranes, hair cell motion). For conductive hearing studies, functional correlation between middle ear chechanics and the air-bone gap have been established. Certainly the understanding of a variety of common hearing disorders and diseases have been expanding.

Faster Diagnosis

Without pain or discomfort, a trained MD can measure the umbo response within a few minutes in a regular otology or audiology clinic visit. Past research findings have led to novel and faster diagnosis procedures. Expert clinicians and otosurgeons are able to suggest to more effective procedures and therapies. In the TORP and PORP implantation field, vibrometry helps during the whole process. LDV technology suports the whole implantation processes, from the design and engineering stages, to the quality control procedures, to goverment authorized implant device calibration process, and through the diagnosis and post implantation procedures.

The Right Instrumentation

Tailored to the specific needs of the researcher, clinician, development engineer, and quality assurance manager, vibrometers dedicated to hearing applications come in a variety of configurations. Polytec Inc. offers versatile instruments for audiology and otology. Depending on the researcher goals and objectives it is possible to configure a single point or scanning systems for middle or inner ear studies. Most systems come with a ready-to-use configuration comprising; the laser sensor with integrated optics, video camera data acquisition and software. Special configurations for in-vivo measurements include operating microscope micro-manipulators for guiding and steering the laser beam during surgery. Advances in technology make our new line of products (VibroFlex) a great choice for improved resolution in the order of picometers.

Data Acquisition and Management System

Easy-to-use data acquisition and software for response measurements is necessary, for these applications. Polytec sensors and software provide the following features and benefits:

- Data multi-channel management and acquisition for signals originating from the vibrometer (velocity/ displacement), probe microphones (sound pressure), pressure transducers, make the work less laborious.

- Acquisition and analysis in time and frequency domains provides a varietyu of data formats for reports and post-processing with easily export formats, plots and video

- User-selectable waveform generation aids the researcher to mimic actual impulses.

- Three-dimensional, animated deflection shapes

- Live video image and storage

- Remote-controlled laser beam positioning and, for scanning measurements, the acquisition of a selected grids

Easy System Operation

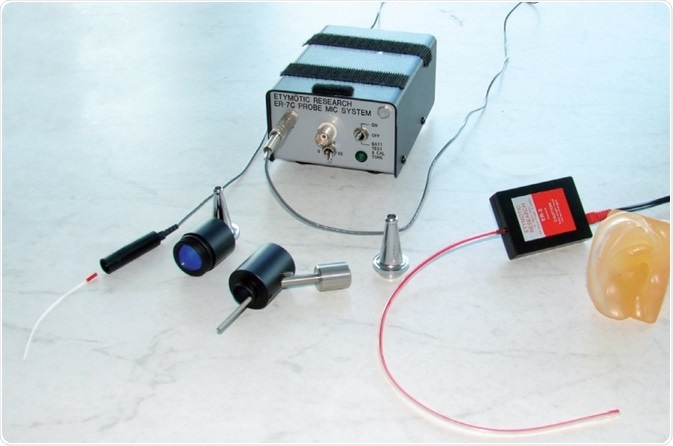

Steering the micron-sized laser spot onto the desired measurement location using a joystick, the researcher, otologist, audiologist or engineer looks through the microscope and the source generator of the Polytec software transports sound excitation through an earphone. A small adapter connected to a standard Storz speculum and a probe microphone simultaneously measure the sound pressure level (SPL) a few millimeters from the tympanic membrane when making measurements of it on a living subject. The LDV sensor then measures the mechanical response.

A-HLV-SPEC

The Right Configuration for Your Needs

An otologist’s essential package would include the following:

- Laser Sensor

Comprise a low-power laser source, class 2, compact laser vibrometer comprising an interferometer head with integrated video camera and digital demodulation.

- Data Acquisition and Visualization

A data management system running acquisition software processes the signals. It includes several acquisition channels, an integrated signal generator for excitation, live video image display, remote control of the vibrometer settings and the software to manage all.

- Microscope Integration

Zeiss or Leica microscopes are used for visualization and positioning of the laser beam via joystick, with a laser micro-manipulator, which couples the sensor head to the operating microscope, allowing the exact positioning of the laser beam onto the specimen or location of tha patient's ear.

- Accessories

There a pletora of accessoried like special speculua adapters, which feature a laser-adapted sealing window, is suitable for all Bruening-compatible Storz specula. Designed for the adaptation of the sound sources (ER-2) and the reference microphones (ER-7C from Etymotic Research) sound source, microphone, this accessory allows sound pressure generation in a sealed space which is directed unto the tympanic membrane.

A-HLV-MM30 Micro Manipulator

From Single Point to Full Field

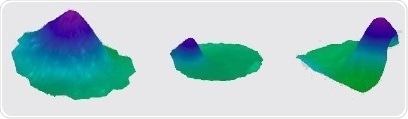

For mid-sized areas down to 1 mm x 1 m, Polytec Scanning Vibrometers can detect the deflection shapes of the tympanic membrane or of hearing aids and its components. Similarly, laser vibrometry is used to acquire full-field vibrational information about the tympanic membrane or other areas of the ear. For hearing aid research and further development within the field, microscope-based LDVs such as the MSA-600 Micro System Analyzer are available for micro-sized models.

PSV-400

Full-field scanning measurements of the tympanic membrane (TM).

Left: normal; center: stapes fixation; right: TM perforation

(Courtesy H. Mojallal, MHH Hannover)

About Polytec

For over 50 years Polytec has provided high-technology, optical-based measurement solutions to researchers and engineers. Our commitment is to provide the most precise and reliable optical instruments and sensors available for non-contact measurement, setting Polytec apart from the competition as the gold standard in the design and manufacture of vibrometer and velocimeter systems. Our innovations answer many pressing manufacturing and engineering challenges.

Polytec was founded in 1967 to distribute commercial laser technology to industrial and research markets. Building on the company’s early success, Polytec began to develop and manufacture innovative laser-based test and measurement instruments in the 1970’s. These products have become known around the world as the gold standard in non-contact, laser-based measurement of vibration, speed and length.

Advanced product development remains a core strategic activity at Polytec with new electro-optical systems being designed for applications such as analytical process measurement, noise analysis, and factory automation.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.