Sponsored Content by PolytecJan 14 2020

The World Health Organization reports that 360 million people worldwide are affected by hearing loss, generally caused by disease, accidents or damage to middle-ear structures. Researchers at University Hospital Zurich measure vibration patterns on impaired ear structures to improve hearing aids and develop clinical diagnostic procedures.

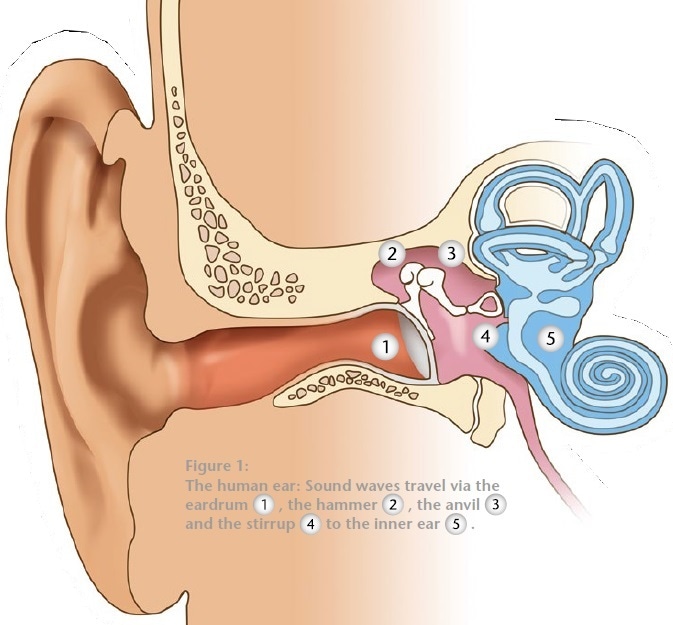

How do we perceive sounds and alert signals? This research focuses on the smallest bones in the human body, the ossicular chain. As well are protecting from impeding danger while asleep or awake, communication is key for the sensory organ that is the ear. Therefore, acoustic sound waves are nothing more than fluctuations in air pressure. To generate the perception of hearing, the hair cell movement creates nerve impulses. The vibration of the eardrum is transmitted through the ossicular chain of the middle ear to the inner ear and is caused by the acoustic sound waves collected by the pinna traveling through the ear canal.

The University Hospital of Zurich has studied and compared damaged and healthy middle ears to investigate surgical treatments. As a reduction in hearing ability can be the cause of damaged middle-ear sound transmission line, the university has assessed the vibration patterns of damaged versus intact middle ears using Polytec instrumentation. The corresponding measurement results in both types of middle ears aided in developing current diagnostic procedures and in finding optimal hearing aids sound transmission mechanisms.

On the other hand, the measurement results research has provided information on development and optimization of middle-ear prostheses and related surgical procedures, such as bypassing the damage and inserting middle ear prostheses, which can offset the impaired sound transmission line. Treatments with middle-ear prostheses include the replacement of the entire ossicular chain or a part of the ossicular chain, for example, the stirrup with a prosthesis. The measurements in our current work focus on the functional roles of the hammer-anvil joint.

Experimental Setup

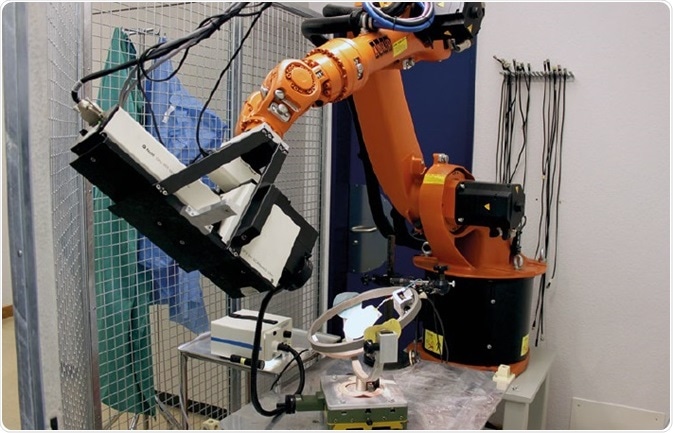

Temporal bones make up the ossicular chain, whereby it vibrates when the eardrum is stimulated with a loudspeaker. While the stirrup vibrations are measured with a scanning laser vibrometer system, a microphone in the ear canal monitors the loudness of the stimulation. The preferred position of the scanning laser vibrometer is coordinated by a robot arm (KUKA KR-16, position repeatability <± 0.05 mm), meanwhile a video camera (VCT 24) captures the scanned area.

From the contrast in the stirrup vibration between the functioning and immobilized hammer-anvil joints, the role of this joint in the middle-ear sound transmission can be deduced. The reflection of the laser beam is optimized with 50 μm diameter retro-reflective glass beads. At several frequencies, the vibration measurements of the stirrup are made and then repeated for the immobilized hammer-anvil joint.

Figure 1: The human ear: Sound waves travel via the eardrum(1) , the hammer (2), the anvil (3)and the stirrup (4)to the inner ear (5).

Figure 2: Experimental setup: the robot arm enables control of the desired position of the scanning-laser-vibrometer so that vibration of the stirrup can be measured as well as vibrations of the temporal bone.

Figure 3: Example of a middle-ear prosthesis: stirrup-prosthesis (NiTiBOND® ): the immobilized stirrup is replaced by a mobile prosthesis. Thanks to the prosthesis, sound transmission is restored and hearing capacity improved.

Results and Applications

The question of the influence the hammer-anvil joint has on sound transmission in the middle-ear is answered with preliminary data, which suggests that the joint influences the frequency content of vibrations in the stirrup. The behavior of the virtual middle-ear can be based on these results, potentially providing a protective hammer-anvil joint damping function against sudden air pressure and high-intensity sounds, possibly explaining the effect the hammer-anvil joint has on age-related hearing loss.

Much like NiTiBOND®, a new stirrup prosthesis that has already been developed and brought to market by KURZ® and the Institute of Engineering and Computational Mechanics at the University of Stuttgart, in future, developing middle-ear prostheses that bypass conductive hearing loss will improve and optimize hearing.

About Polytec

For over 50 years Polytec has provided high-technology, laser-based measurement solutions to researchers and engineers. Our commitment is to provide the most precise and reliable optical instruments and sensors available for non-contact measurement, setting Polytec apart from the competition as the gold standard in the design and manufacture of vibrometer and velocimeter systems. Our innovations answer many pressing manufacturing and engineering challenges.

Polytec was founded in 1967 to distribute commercial laser technology to industrial and research markets. Building on the company’s early success, Polytec began to develop and manufacture innovative laser-based test and measurement instruments in the 1970’s. These products have become known around the world as the gold standard in non-contact, laser-based measurement of vibration, speed and length.

Advanced product development remains a core strategic activity at Polytec with new electro-optical systems being designed for applications such as analytical process measurement, noise analysis, and factory automation.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.