Sponsored Content by PolytecJan 14 2020

In both developed and developing countries, advanced point-of-care diagnostic systems are needed for testing patients outside centralized hospital laboratories and other such facilities. Diseases such as malaria, sleeping sickness (Human African Trypanosomiasis or HAT), and tuberculosis still take a substantial toll on the population in the developing world particularly.

At the University of Glasgow, Professor Jon Cooper and his accompanying researchers have developed an ultrasonic- and nanometer-based vibration technology, generating vibrations at the surface of microchips to influence liquid samples and incorporate diagnostic tests onto disposable portable systems. Laser vibrometry allows vibration characterization on these surfaces so that our designs can be validated with high spatial resolution and high data density.

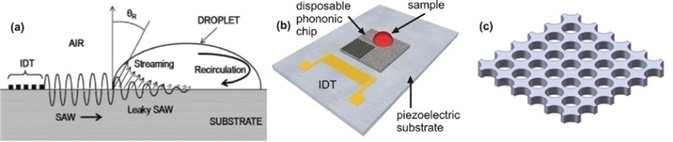

A significant number of ultrasonic transducers have been developed, mostly in consumer electronics, such as surface acoustic wave (SAW) devices for sensing and microfluidic manipulations [Friend, J. & Yeo, L., Rev Mod Phys, 2011, 83, 647], as shown in Figure 1a. Glucose personal management for diabetes, and a few other tests of this ilk, have moved from centralized facilities to being performed at point-of-care, directly alongside patients. Ultrasound is used by us to perform all of the various functions required to run a complete diagnostic evaluation of low-cost disposable devices.

Ultrasonic waves are coupled into a phononic lattice in our newly developed platform, a miniaturized array of mechanical features, as shown in Figures 1b and 1c. The ultrasonic field is modulated by the elastic contrast between the elements in the phononic array and the matrix surrounding them [R. Wilson et al. Lab Chip, 2011, 11, 323], analogous to how differences in refractive indices within the elements of a hologram can ‘shape’ light.

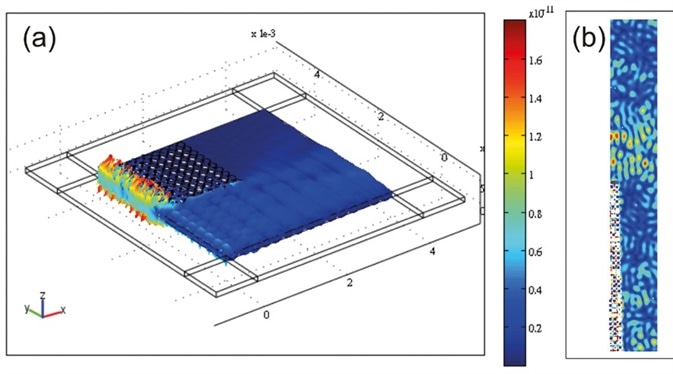

We have applied this technology to an integrated nucleic acid-based test which diagnoses malaria in just one implementation. This examination analyzes the genetic material of the parasite, which is located within red blood cells in the blood of infected patients. Figure 2 shows simulations and vibrometer measurements in order to explain the use of a phononic device to shape the waves to execute these specific functions.

Figure 1: (a) SAW propagating on a piezoelectric substrate transferring mechanical energy into a liquid sample; (b) an alternative format where a phononic bandgap structure is patterned onto a disposable superstrate, which is placed on the piezoelectric substrate; (c) Example schematic of a phononic lattice (holes of 80 μm in diameter).

Figure 2: A phononic filter was (a) simulated (Comsol Multiphysics) and (b) measured using laser vibrometry (UHF, Polytec) at 9.35 MHz excitation. Results (vibration amplitude) show the attenuation of the waves within the structure (represented by the array of empty holes in the measurement (b)) while they propagate outside of it. The device is ca. 1.5 cm wide.

Vibrometry Measurements

A Polytec UHF-120 system completed the measurements with a 9.35 MHz excitation. To obtain a valid result on vertical amplitudes below 1 nm and at resolutions below the 100 μm wavelength, the origins of these scans lie with the varying scales involved in the measurements. This resulted in extended scans to cover the sufficient area (a liquid sample of a few mm). Scans such as these have sometimes taken as long as ten days to cover cm-wide spaces (see Figure 3).

![Vibrometer scan revealing the amplitude of vibrations in a phononic cone, able to focus the energy at specific locations. Scan of ca 190 000 points at 9.35 MHz. [Reboud J., et al, Lab Chip, 2012, 1268-73] – scale bar is 200 μm. Vibrometer scan revealing the amplitude of vibrations in a phononic cone, able to focus the energy at specific locations. Scan of ca 190 000 points at 9.35 MHz. [Reboud J., et al, Lab Chip, 2012, 1268-73] – scale bar is 200 μm.](https://www.news-medical.net/image-handler/picture/2019/8/1980_Art6_Pic3.jpg)

Figure 3: Vibrometer scan revealing the amplitude of vibrations in a phononic cone, able to focus the energy at specific locations. Scan of ca 190,000 points at 9.35 MHz. [Reboud J., et al, Lab Chip, 2012, 1268-73] – scale bar is 200 μm.

Conclusions

An essential tool of the development process and design validation, laser vibrometry allows the visualization of vibrations on the surface across entire microchips. Malaria has been detected [Reboud J. et al., PNAS, 2012, 15162-7] and displayed from a drop of blood obtained by a finger prick, using an acoustic filter.

The vast potential of phononic surface acoustic wave devices could enable the point-of-care diagnostics to be integrated, using the mechanical energy carried by sound to employ and analyze liquid patient samples on low-cost microchips. Likely to happen in the future, the detection of diseases such as tuberculosis will improve via more complex assays being unified on the platform.

About Polytec

For over 40 years Polytec has provided high-technology, laser-based measurement solutions to researchers and engineers. Our commitment is to provide the most precise and reliable optical instruments and sensors available for non-contact measurement, setting Polytec apart from the competition as the gold standard in the design and manufacture of vibrometer and velocimeter systems. Our innovations answer many pressing manufacturing and engineering challenges.

Polytec was founded in 1967 to distribute commercial laser technology to industrial and research markets. Building on the company’s early success, Polytec began to develop and manufacture innovative laser-based test and measurement instruments in the 1970’s. These products have become known around the world as the gold standard in non-contact, laser-based measurement of vibration, speed and length.

Advanced product development remains a core strategic activity at Polytec with new electro-optical systems being designed for applications such as analytical process measurement, noise analysis, and factory automation.

In addition, Polytec continues to develop its key business structure through critical technology acquisitions and focused spin-offs. Some of the most recent highlights include:

In 2005, Polytec PT GmbH Polymere Technologien was founded as a spin-off, with over 30 years of know how in the supply and application of high tech adhesives and silicones in demanding electronic, optical and medical industries.

In 2008, LATAB was acquired and became a member of the Polytec organization. LATAB's early entry into the LED illumination market has produced the broadest and most flexible product mix for technical applications.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.