Key issues

- Butter adulteration is a widespread type of food fraud

- QA/QC of butter is carried out in the laboratory

- Specialized training is required to perform time-intensive laboratory measurements

Raman spectroscopy

- Raman spectroscopy quantifies the sample’s chemical composition

- Raman spectroscopy can be efficiently performed with minimal requirements for sample preparation

- Margarine can easily be differentiated from butter using Raman

- Investigation outlines the measurement of margarine in butter

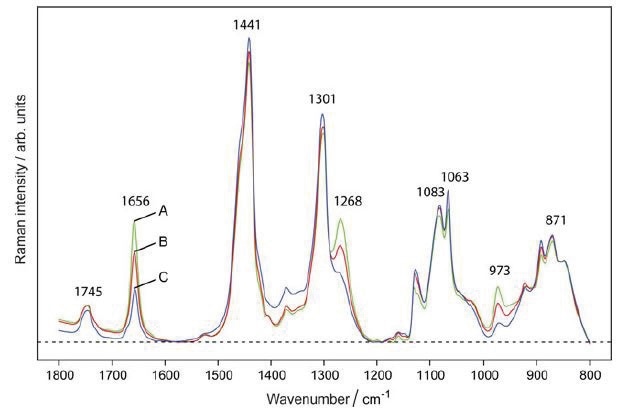

Figure 1. Raman spectra of (A) margarine, (B) 50:50 margarine–butter mixture, and (C) butter show that peaks at 973, 1268, and 1656 cm−1 are indicative of margarine in the sample. Image Credit: Reprinted with permission from Ref. 1. © 2016 Springer.

Introduction

Public health and consumer confidence are harmed by the adulteration of food products, particularly in developing countries. Dairy products such as butter, liquid milk, and milk powder are popular targets for adulteration as they are costly to create.

The adulteration of butter with margarine, plant-based oils, or starch is a widespread technique. Identifying these inexpensive items in butter is complex. The mouth-feel or taste of butter is not changed by the presence of these items, so the consumer is unable to detect adulterated butter. Chemical analysis is the only way to detect this.

Chromatography laboratory-based quantification can be employed, but this method is costly and specially trained staff and consumables are required.

Raman advantages

Raman spectroscopic methods are now being tested as the results are efficient, specific, and the material does not need to be damaged or prepared. Raman spectroscopy’s specificity is particularly beneficial as it can distinguish vegetable fats from milk fat.

Raman-based screening techniques could be automated and standardized. This article describes an efficient, precise method for quantifying margarine content in butter utilizing Raman spectroscopy.1

The Raman method shows promise for an easy-to-use and robust operation, with the possibility to be used as a technology platform to verify the integrity of dairy products.

Experimental

Commercially available samples of pure margarine, pure butter, and graded blends of the margarine and butter were prepared and investigated. To account for heterogeneity, 30 spectra were gathered on each sample with a twenty-second acquisition time for each.

The R statistical software package was used to analyze the data. The spectra were normalized and baseline-corrected, and the spectral range was limited to 800 to 1800 cm−1, which comprised information to simply differentiate between margarine and butter in the samples.

PCA was utilized to design a quantitative model for the margarine and butter in the samples.

Results

Spectra of butter, margarine, and a 50:50 combination of the two are displayed in Figure 1. The existence of bands could differentiate margarine at 1268 and 1656 cm−1 correlated with the C=C double bond and at 973 cm−1, related to the choline group in the phospholipid.

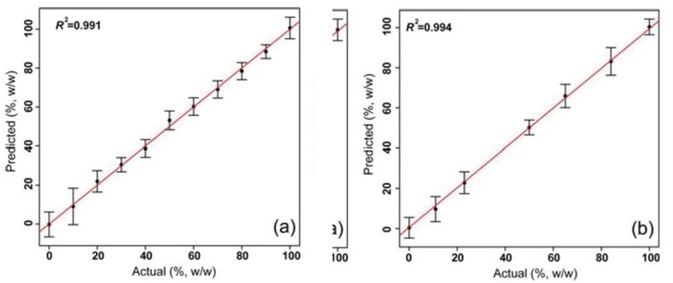

Known values quantified by weight agreed with the Raman-predicted margarine content, as shown in Figure 2. Principal Components Analysis (PCA) was utilized to determine spectral areas that could differentiate margarine from butter.

Figure 2. Predicted versus actual values of margarine in mixed samples: (a) calibration, (b) test. Measured values corresponded closely with predicted. Image Credit: Reprinted with permission from Ref. 1. © 2016 Springer.

The PCA data verified that the known chemical moieties of margarine (the choline group and the C=C double bond) changed according to concentration. Negative peaks identified margarine content in the calibration samples at 973, 1268, and 1656 cm−1.

Partial Least Squares Regression (PLSR) was used to measure the quantity of margarine in test and known samples. PLSR validated positive overall model performance, displayed in Figure 2.

At the locations of the margarine peaks at 973, 1268, and 1656 cm−1, PLSR coefficient plots displayed large positive values. The model estimated margarine content with an RMSECV=3.199 and R2=0.991 for the calibration data. The model estimated margarine content with an RMSEP=2.757 and R2=0.994 for the test data.

The PCA of model mixtures and the spectra displayed in Figure 1 shows that the three Raman peaks at 973, 1268 and 1656 cm−1 can be assigned to vegetable fat in margarine and that those peaks can be used to measure the content of margarine in butter.

This crucial function means that the fat does not have to be separated from the rest of the sample, as was required in the conventional chromatographic technique. The exclusion of the fat-extraction stage is a huge advancement toward analysis automation.

Conclusions

Raman spectroscopy for the analysis of margarine adulteration in butter shows a substantial improvement over the conventional chromatographic technique. The model produced in this investigation was robust to the margarine concentration in the samples.

The Raman technique was easy to perform and removed the requirement for a fat-extraction stage necessary in chromatography. Raman spectroscopy offers significant potential as a dependable technique for routine QA/QC of butter and additional dairy products.

References and further reading

- Nedeljković, A., Rösch, P., Popp, J., Miočinović, J., Radovanović, M., and Pudja, P.; “Raman spectroscopy as a rapid tool for quantitative analysis of butter adulterated with margarine” Food Analytical Methods, 2016, 9(5), 1315–1320.

About Kaiser Optical Systems, Inc.

Kaiser Optical Systems, Inc. (Kaiser), an Endress+Hauser company, is the global leader in Raman spectroscopic instrumentation for laboratory, process, and manufacturing environments. Our solutions harness the powerful analytical information of Raman Spectroscopy to help our customers understand, measure, and control their chemistries.

As a trusted partner in Raman for over 30 years, Kaiser has a long history in production, including GMP manufacturing, with many proven successes. Our unmatched expertise, high quality solutions, and exceptional customer service sets Kaiser far above any other Raman option in the marketplace. Kaiser Raman technology is currently used throughout the chemical, food and beverage, oil and gas, pharmaceutical, and biopharmaceutical industries to optimize process efficiency and deliver quality products. Kaiser’s manufacturing and headquarters facility is in Ann Arbor, Michigan.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.