Key Issues

- Nondestructive analysis of melted fat and intact pork fat

- Fast analysis amenable to on-line quality control during meat processing

- Determination of IV, MUFA, PUFA, and SFA in minutes

Introduction

Unsaturation of fat content in pork meat is a vital measure of pork meat quality. Pork fat consists of proportions of various fatty acids, and those proportions impact quality, flavor and storage compatibility. A high level of unsaturated fatty acids makes the meat vulnerable to oxidation, a major source of off-flavoring. Establishing the unsaturation level rapidly during processing can also be beneficial in quickly discerning which meats are suitable for fresh or cured products.

Presently, fat unsaturation is measured utilizing time-consuming chemical methods and there is interest in fast, non-destructive quantification of fat tissue during processing. Raman spectroscopy is a promising tool for non-destructive, fast, pork fat analysis.

In this article, Raman spectroscopy was utilized to quantitate the average amount of unsaturation in pork fat tissue to be able to show the feasibility of Raman for this application. The amount of unsaturation is expressed as the iodine value (IV). A single Raman spectrum measured the IV, monounsaturated fatty acids (MUFA), saturated fatty acids (SFA) and polyunsaturated fatty acids (PUFA) simultaneously.

Methods

The average amount of unsaturation in pork back fat was established by Raman spectroscopy on seventy-seven samples of melted fat tissue and intact pork back fat tissue from the same carcass. Spectra were obtained utilizing a probe coupled by optical fibers to a Kaiser Raman analyzer, operating at 785 nm with an Invictus™ laser. Measurements were conducted by placing the probe into direct contact with the sample and recording a spectrum by averaging three replicates of 20 seconds at a time.

Two spectra were obtained on each side of intact adipose tissue samples, offering an average fatty-acid profile. An average is most applicable to meat processing applications. Melted fat samples were measured in two averaged spectra at 47 to 50 °C. Intact adipose tissue samples were measured at a temperature of 20 °C, then homogenized and melted. Reference analysis was conducted by gas chromatography utilizing typical IV, MUFA. FLA and PUFA, measurement protocols.

Results

Raman spectroscopy of the fat samples gave easily quantifiable and recognizable peaks. Figure 1 illustrates Raman spectra of both melted fat (solid line) and adipose tissue (dotted line). Key lipid bands are in sections 1 and 2, corresponding to the 1200-1800 cm-1 and 2600-3100 cm-1 spectral regions.

Figure 1. Raman spectra of intact pork fat tissue (dotted line) and melted pork fat (solid line) provide information on fatty acid saturation. Peaks related to lipids in pork tissue are noted in sections 1 and 2. Bands from the sapphire probe, in section *, do not interfere with collection of tissue Raman bands. Image Credit: Adapted from and reprinted with permission from Ref. 1. © 2007 Elsevier.

Both melted fat and intact fat tissue were measured easily. Due to the fact spectra could be obtained in approximately one minute, it is feasible for Raman to be applied directly to tissue measurements on-line at the processing plant. The average amount of unsaturation is the crucial value for this application. To provide a quick and thorough characterization, the amount of unsaturated and saturated fatty acids is also measured,.

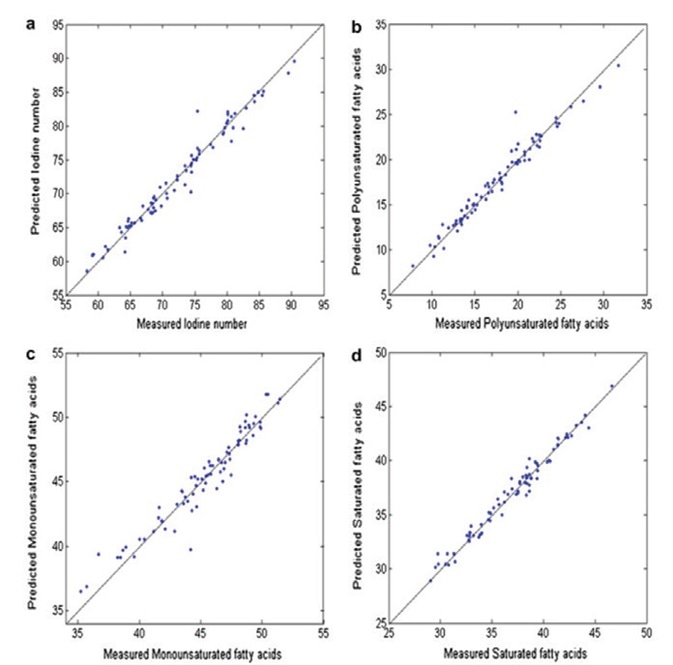

Figure 2 illustrates predicted versus measured values for IV, MUFA, SFA and PUFA, in adipose tissue. All parameters showed decent correlation. A three-factor partial least squares (PLS) regression model resulted in correlation coefficients (R) between 0.91 (for MUFA) and 0.97 (for IV). Results for melted fat were comparable and even slightly better, ranging from R = 0.96 for MUFA to R = 0.98 for IV.

Figure 2. Predicted versus measured values of (a) iodine value, (b) polyunsaturated fatty acid content, (c) monounsaturated fatty acid content, and (d) saturated fatty acid content in adipose tissue. Image Credit: Reprinted with permission from Ref. 1. © 2007 Elsevier.

The low prediction errors suggest that Raman can offer data like conventional chemical methods. Critically, Raman offers this information quickly and with no sample preparation required. Due to Raman data being produced from multiple sites on each sample, Raman data matched the data generated by chemical methods on homogenized samples. The averaged degree of unsaturation provided by Raman is consistent with processing standards to treat the carcass during processing.

Conclusions

This laboratory study demonstrates that Raman spectroscopy can offer both an effective and quick analytical method for determining IV, MUFA, SFA and PUFA in samples of pork back fat, simultaneously. Raman has been reported as a strong and transferable method for IV measurements.2 Controlling unsaturation through breeding, gender and diet can aid in processing and storage. Raman has been demonstrated to be a key tool for optimizing feeding strategies to control pork fat unsaturation.3 The Kaiser Raman analyzer is capable of small area sampling to large volumetric sampling for processing plant or laboratory measurements.

References

- Lee, H.; et.al. Prediction of Crude Protein and Oil Content of Soybeans Using Raman Spectroscopy. Sensors and Actuators B: Chemical 2013, 185, 694–700.

- Jiménez-Sanchidrián, C.; Ruiz, J. R. Use of Raman Spectroscopy for Analyzing Edible Vegetable Oils. Applied Spectroscopy Reviews 2016, 51 (5), 417–430.

- Dymińska, L.; et.al. Quantitative Determination of the Iodine Values of Unsaturated Plant Oils Using Infrared and Raman Spectroscopy Methods. International Journal of Food Properties 2017, 20 (9), 2003–2015.

About Kaiser Optical Systems, Inc.

Kaiser Optical Systems, Inc. (Kaiser), an Endress+Hauser company, is the global leader in Raman spectroscopic instrumentation for laboratory, process, and manufacturing environments. Our solutions harness the powerful analytical information of Raman Spectroscopy to help our customers understand, measure, and control their chemistries.

As a trusted partner in Raman for over 30 years, Kaiser has a long history in production, including GMP manufacturing, with many proven successes. Our unmatched expertise, high quality solutions, and exceptional customer service sets Kaiser far above any other Raman option in the marketplace. Kaiser Raman technology is currently used throughout the chemical, food and beverage, oil and gas, pharmaceutical, and biopharmaceutical industries to optimize process efficiency and deliver quality products. Kaiser’s manufacturing and headquarters facility is in Ann Arbor, Michigan.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.