Since pipetting serial dilutions is a time-consuming process and is consequently prone to errors, particularly in 384 well plates, pipetting serial dilutions reproducibly can be very difficult. The human influence impacts most on pipetting results, assuming that pipettes are properly maintained and calibrated. In order to improve reproducibility and accuracy, good pipetting practice should be observed.

This article focuses on a range of good pipetting techniques, which when followed provide the best way for enhancing and maintaining the reproducibility of serial dilutions. This article also discusses different mixing parameters to help users achieve a homogenous sample, as mixing is a vital component of dilution protocols.

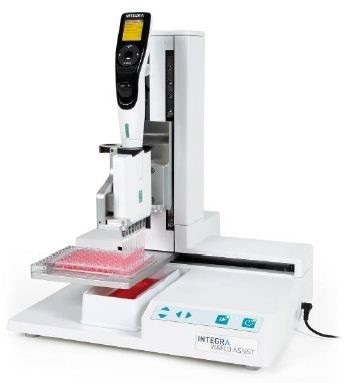

Automating the process provides many benefits as it maximizes consistency of dilution assays. In addition, the article outlines the features an automated pipetting system must have to ensure high reproducibility of serial dilutions and introduces the ASSIST, a custom-designed product for this task.

Introduction to Good Pipetting Practice

To ensure that pipettes are employed in an optimal and reproducible way, good pipetting practice elucidates guidelines to cover the basic techniques.

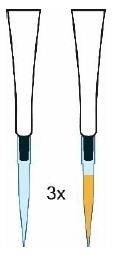

Pre-wetting of pipette tips should be performed prior to preparing the assay. This can be done by aspirating and dispensing the full volume two to three times. This process equilibrates the temperature differences between tip and liquid, and humidifies the dead air space inside the tip and pipette. Errors could be introduced into the subsequent dilution steps if pre-wetting is not done, which results in a smaller delivery volume in the initial dispenses.

When the liquid is drawn, the inclination angle of the pipette also influences the liquid volume in the tip. The pipette should be held at a consistent angle, maximum 20° during the dilution process.

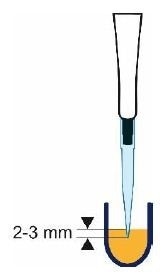

To aspirate the desired volume, the pipette should be dipped just below the liquid surface. If the tip is dipped too much, there is an increasing risk of carry-over as liquid drops can cling to the outer surface of the tip.

However, in reality, even the most conscientious laboratory personnel do not always follow the rules of good pipetting practice. The technique can become inconsistent, especially when carried out tired or in a hurry. Additionally, there is an increased risk of translational errors.

When handling colorless liquids, a row in a 96 or 384 well plate can get easily skipped, which ruins an entire plate and forces the users to start afresh. Hence, it is no surprise that different users who use the same pipette may end up with varying pipetting results based on their level of experience and training, and their working hours.

Optimizing Mixing Parameters

When preparing a dilution series, the contents of each well should be thoroughly mixed in the microplate. If an inhomogeneous mixture is used, it can create a substantial error which will be carried on to the succeeding dilution steps, resulting in a concentration which will be different from the assumed hypothetical concentration across the plate. Therefore, it is important that the mixing parameters such as the number of required mixing steps, mixing height, and mixing speeds for a particular liquid are optimized.

It may be necessary to adapt the pipetting speed, depending on the liquid’s viscosity. Viscous liquids should be pipetted slowly so that the liquid can flow through the orifice of the small tip.

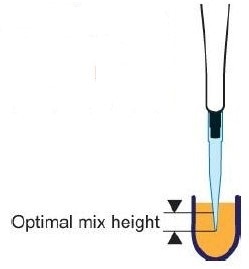

Due to the generation of insufficient turbulence, mixing with the tip end at the bottom of a microplate well leads to a poorer mix. Usually, the middle

of the liquid column of a well or higher, is the most efficient mixing height. Ideally, during the mixing process, the liquid is dispensed on top and then aspirated from the middle. This can prove to be tricky if performed manually, and so care should be taken not to remove the tips from the liquid at the time of mixing to avoid air being drawn in.

The mixing result is also affected by the number of mix cycles and the mix volume. A more homogenous mix results when the number of mix cycles is increased and a larger mix volume is employed, but this can significantly increase the preparation time for the assay.

How Automation Can Help

While preparing a series of serial dilutions with a handheld pipette, it becomes difficult to observe these good pipetting and good mixing practice factors. A total of 110 manual plunger movements are required to perform a serial dilution in a 96 well plate with five mix cycles for each row, and added to this, users may get a potential strain on their wrist and thumb if this process is performed for a long time. This process can be improved by an electronic pipette as it allows the number of mix cycles (including speeds) to be defined and automatically run through the cycles, without having users to constantly press the plunger.

Pipetting practice and mixing issues can be avoided and a consistent workflow can be achieved by automating the pipetting process. The entire dilution process is controlled by an optimal automation system, allowing it only necessary for users to define the key parameters such as mixing speeds and heights for serial dilutions.

A high investment or dedicated personnel, required by a fully-automated system or a laboratory robot, are not needed to achieve the preferred automation in many dilution applications. Fortunately, Integra’s ASSIST provides all the functionality, speed, and the necessary automation at a much lower price tag. When a VIAFLO electronic multichannel pipette is clicked, the ASSIST turns into a reliable pipetting assistant by always observing good pipetting practice, never getting tired, and carrying out the serial dilution, from distributing the diluent to diluting the sample.

Lauren Anderson Dring, research scientist and project manager at Pulmocide says, “The ASSIST has become an integral part of our compound screening process. It is used on a daily basis to produce reproducibly accurate drug dilutions in a medium throughput manner.”

All important parameters can be set with the ASSIST for efficient mixing in serial dilutions —mixing height, number of mixing cycles, and pipetting speeds. Ms. Dring added “The ASSIST is particularly useful in that a multitude of parameters can be pre-defined, such as volume and pipette mixing speed, thus allowing us to set up and save a variety of dilution protocols to suit our needs.”

Besides allowing a fixed height to be set, the ASSIST allows the liquid within the microplate wells to be tracked, thus avoiding the necessity to dip the tip too much and reducing the potential carry over. A pre-wet can be done by hand before the start of the program or it can be incorporated into the ASSIST program to conform to the good pipetting practice.

Conclusion

It is a challenging task to prepare reproducible serial dilution assays since they necessitate multiple pipetting actions and depend on an operator’s experience and technique. Better pipetting results can be achieved if good pipetting practices are observed. However, an automated pipetting system becomes necessary if the aim is to streamline the serial dilution process and to ensure maximum reproducibility.

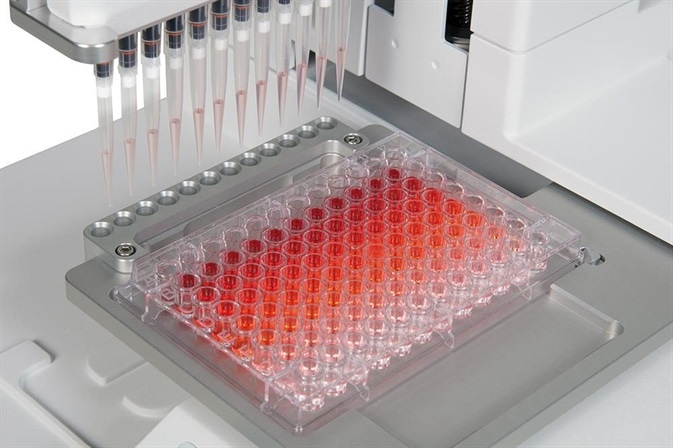

Automating a serial dilution on a 96 well plate with ASSIST.

The ASSIST is a highly capable, easy-to-use, affordable automated pipetting platform designed to perform serial dilutions in microplates. Pipetting results are improved if pipetting speeds and heights and other important parameters are precisely controlled. The overall pipetting consistency is improved with the automated platform, such that inconsistencies and human errors are eliminated to result in more reproducible assays and time savings.

Acknowledgements

Produced from materials originally authored by Michael Beier, Liquid Handling Product Manager at INTEGRA Biosciences.

About INTEGRA

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

Their instruments and plastic consumables are developed and manufactured in Zizers, Switzerland and Hudson, NH USA. In order to remain close to their customers, they maintain a direct sales and support organization in North America, the UK, France and Germany, as well as a network of over 100 highly trained distribution partners worldwide.

In recent years they have focused on developing a new and technologically advanced range of handheld electronic pipettes which are simple to use and meet the ergonomic needs of their customers.

Today they are proud to offer the widest range of electronic pipettes in the market spanning a range from single channel pipettes up to 384 channel bench-top instruments.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and iform site visitors interested in medical research, science, medical devices and treatments.