It is becoming increasingly evident that the recapitulation of the in vivo cell environment is more advanced in 3D rather than traditional 2D methodologies. This is leading to an increase in spheroid and other 3D models being employed for drug discovery. Therefore, a high throughput system is crucial to meet the requirements of most high-volume drug discovery programs.

The Corning 1536-well spheroid microplate can produce 1536 uniform, single spheroids that can be assayed via luminescence, fluorescence, or imaging directly in the microplate.

Precision with liquid handling is essential to the generation of quality data due to the maximum volume of 14 µL per well. Consequently, we have developed an automated method for seeding, dosing, and assaying spheroids in a Corning 1536-well spheroid microplate format with the aid of INTEGRA Biosciences’ liquid handling instruments. Designed for rapid bulk liquid dispensing at volumes as low as 0.5 µL the VIAFILL can be fully automated with a plate stacker attachment.

The VIAFLO 384 is a handheld electronic pipetting system which allows for transfer into 24-, 96-, 384-, and 1536- well microplates in a rapid, compact, and straightforward way. This methodology demonstrates reliable data for assay development and the ability to produce high throughput screens.

Materials and Methods

Spheroid Formation

The cells DU 145 (ATCC® HTB-81) and PANC-1 (ATCC CRL-1469™) were regularly cultured in Dulbecco’s Modification of Eagle’s Medium (DMEM; Corning Cat. No. 10-013-CM) containing 10% fetal bovine serum (FBS; Corning Cat. No. 35-010-CV).

Using the VIAFILL with the 16-channel dispensing cassette (INTEGRA Biosciences Cat. No. 5742), cells were dispensed into 1536-well spheroid microplates (Corning Cat. No. 4527) at 1 x 103 cells per well in a volume of 5 µL per well.

To accommodate spheroid formation, microplates were incubated overnight at 37 °C in a humidified CO2 incubator.

Homogenous Cell-based Assay

Subsequent to DU 145 spheroid formation, 1 µL of 6 µM staurosporine (MilliporeSigma Cat. No. 569396) or buffer control was seeded into each well via the VIAFLO 384 with a 384-channel pipetting head (0.5-12.5 µL) and 12.5 µL short GripTips (INTEGRA Biosciences Cat. No. 6475). The following day, each well was given 6 µL of CellTiter-GLO® 3D (Promega Cat. No. G9683) and then allowed to incubate at room temperature for 1 hour. Using a TECAN Infinite® M200 microplate reader, the luminescent signal was then recorded.

High-content Imaging Assay

Once spheroid formation had occurred, both DU 145 and PANC-1 spheroids were mixed with various concentrations of cisplatin (Sigma- Aldrich/MilliporeSigma Cat. No. 1134357) by adding 1 µL via the VIAFLO 384 with 12.5 µL short GripTips - the plates were incubated overnight.

By adding 6 µL of 40 µg/mL Hoechst 34580 (Thermo Fisher Cat. No. H21486) and 16 µg/mL propidium iodide (PI; AnaSpec Cat. No. 83215) in phosphate buffered saline (PBS; Corning Cat. No. 21-030-CM) to each well enabled the assessment of cytotoxicity. Microplates were then imaged on the Thermo Fisher CellInsight™ CX7 high-content screening platform.

Results

Assay Robustness

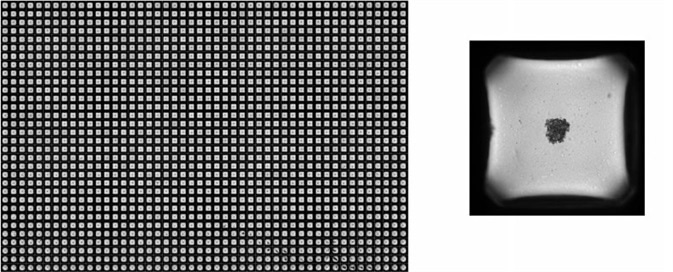

The ability to generate a single, uniform spheroid in each well (Figure 1) is down to the distinctive design of the Corning 1536-well spheroid microplate. Precise liquid handling of the cell suspension during seeding is of utmost importance to ensure that the spheroids are consistent in size across the entire microplate. For high-speed cell seeding, the INTEGRA VIAFILL was used (Figure 2). With the ability to accurately seed a 1536-well microplate in less than 1 minute per plate, this bulk liquid dispenser can be paired with a plate stacker for improved throughput. The INTEGRA VIAFLO 384 was then brought into action for compound and reagent addition.

Figure 1. Uniform, single spheroids formed in each well across the entire spheroid microplate. Representative image of single uniform DU 145 spheroids formed in the Corning 1536- well spheroid microplate with one well digitally zoomed in. Images were taken with Thermo Fisher CellInsight CX7 high-content screening platform using a 4X objective.

Figure 2. Microplate dispenser for uniform cell seeding. INTEGRA VIAFILL for rapid, bulk liquid dispensing into 96-, 384-, or 1536-well microplates.

Figure 3. Electronic pipetting system for accurate compound delivery. INTEGRA VIAFLO 384 for increased productivity and efficiency to accurately work with 24-, 96-, 384-, and 1536-well microplates.

With a minimal footprint, the handheld electronic 24-, 96-, and 384-channel pipetting system has the ability to increase throughput and productivity in filling microplates while using disposable tips (Figure 3).

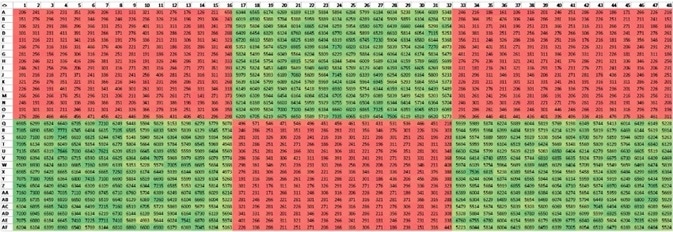

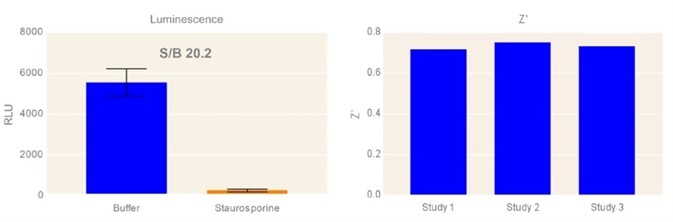

The consistency of signal, signal-to- background ratio (S/B), and calculated Z' values were assessed to illustrate the utility of this innovative design for 3D cell screening. By treating sections of the microplate with a single concentration of buffer or staurosporine to instigate cell death and assaying spheroid viability via homogenous luminescence cell viability assay demonstrated the uniformity of signal.

A heat map of luminescence signal shows strong signal consistency within treatment conditions despite the location within the microplate (Figure 4).

The mean S/B ratio from this assay was upwards of 20 for 3 independent studies (Figure 5). Furthermore, Z' values were continually above 0.7, evidence of the resilient viability assay in the 1536-well spheroid microplate (Figure 5).

Proof of Concept Assay

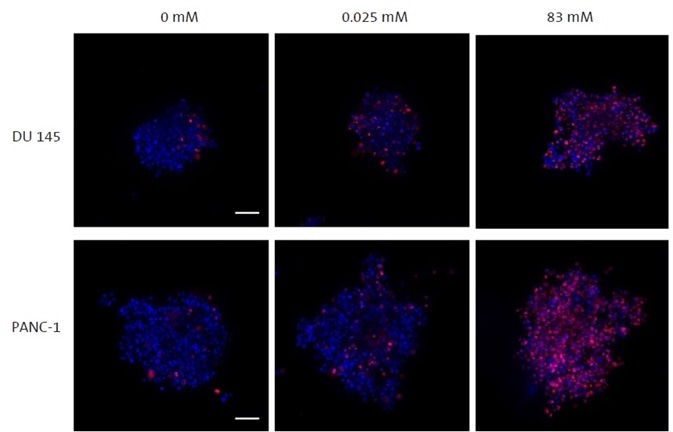

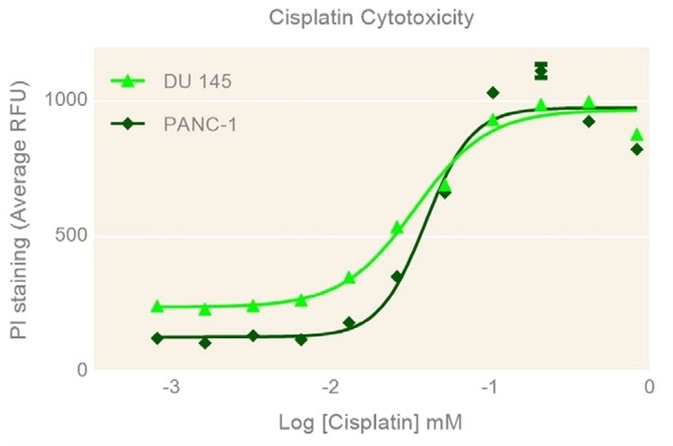

Spheroids DU 145 and PANC-1 that were introduced to varying concentrations of cisplatin were then stained and imaged with the Thermo Fisher CellInsight™ CX7 high-content screening platform. Capturing representative images directly without the need to transfer the spheroids to an additional microplate, evidences the utility of culture and the successive imaging of spheroids in the spheroid microplate (Figure 6). PI staining for image analysis illustrates typical concentration-response curves for cisplatin cytotoxicity with IC50 values of 0.03375 and 0.03917 mM for DU 145 and PANC-1 spheroids, respectively (Figure 7).

Figure 4. Uniform signal across Corning spheroid microplate. Representative image of color-scaled luminescence signal generated from an assay where DU 145 spheroids were exposed to a final concentration of buffer (green) or 1 µM staurosporine (red). Green corresponds to high luminescence values, high viability. Red corresponds to low luminescence values, low viability.

Figure 5. Large, robust luminescence assay window. (A) Mean ± SD luminescence of DU 145 spheroids exposed to buffer or 1 µM staurosporine, resulting in S/B of 20.2. p<0.0001 with unpaired t-test. (B) Excellent Z' values above 0.7 in 3 independent studies. N = 2304 wells in 3 independent studies.

Figure 6. Confocal imaging of spheroids within Corning 1536-well spheroid microplate. Representative z-stack images of DU 145 (top) and PANC-1 (bottom) spheroids exposed to 0 mM, 0.025 mM, and 83 mM cisplatin (left, middle, right, respectively) for 24 hours. Spheroids were stained with Hoechst (blue) and PI (red) to assess cell viability. Spheroids were imaged directly in the spheroid microplate with the Thermo Fisher CellInsight™ CX7 high-content screening platform using a 10X objective. Scale bar = 100 µm.

Conclusions

The appropriate tools are of vital importance to screen large compound libraries against 3D cell models and achieve results of merit. The Corning® 1536-well spheroid microplate enables the formation of stable and constant single spheroids in each well that are perfectly suitable for high throughput 3D drug screens.

The transparent bottom and black sidewall design of the Corning spheroid microplate make it ideal for imaging luminescent and fluorescent cell-based assays.

Because of the small well volume of the 1536-well microplates, meticulous and accurate dispensing is essential. Therefore, using the INTEGRA VIAFILL and VIAFLO 384 instruments for 1536-well spheroid microplate liquid handling results in assays with high signal-to-background ratios with consistently outstanding Z' values.

Figure 7. Concentration-dependent cisplatin cytotoxicity. Mean ± SD fluorescence of DU 145 and PANC-1 spheroids following 24 hours exposure to varying concentrations of cisplatin. N = 96 wells.

About INTEGRA

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

Their instruments and plastic consumables are developed and manufactured in Zizers, Switzerland and Hudson, NH USA. In order to remain close to their customers, they maintain a direct sales and support organization in North America, the UK, France and Germany, as well as a network of over 100 highly trained distribution partners worldwide.

In recent years they have focused on developing a new and technologically advanced range of handheld electronic pipettes which are simple to use and meet the ergonomic needs of their customers.

Today they are proud to offer the widest range of electronic pipettes in the market spanning a range from single channel pipettes up to 384 channel bench-top instruments.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and iform site visitors interested in medical research, science, medical devices and treatments.