In laboratories across the world, it is common to pump and dispense buffer solutions, culture media, or other fluids. Ensuring proper liquid transfer with high precision and free of contamination is a key challenge in using pumps for liquid transfer.

Also, some pump designs, for instance, pumps featuring valves, are susceptible to contamination, or may face issues such as jamming when transferring fluid types such as suspensions or viscous liquids. To overcome these issues, laboratories handling the dispensing of a range of different fluids now increasingly prefer to use peristaltic pumps.

Peristaltic Pumps

In peristaltic pumps, liquid is transferred via a flexible tube often made of silicone by subjecting the tube to a mechanical deformation. This tube squeezing mechanism is known as “peristalsis” - a commonly used principle seen in biological systems such as the gastrointestinal tract for transferring fluids.

Eugene Allen first patented the peristaltic pump in the US in 1881. However, it took nearly half a century for the peristaltic pump to come into the limelight when Dr. Michael DeBakey, a renowned heart surgeon, started using a peristaltic pump as a key part for the first heart-lung-machine.

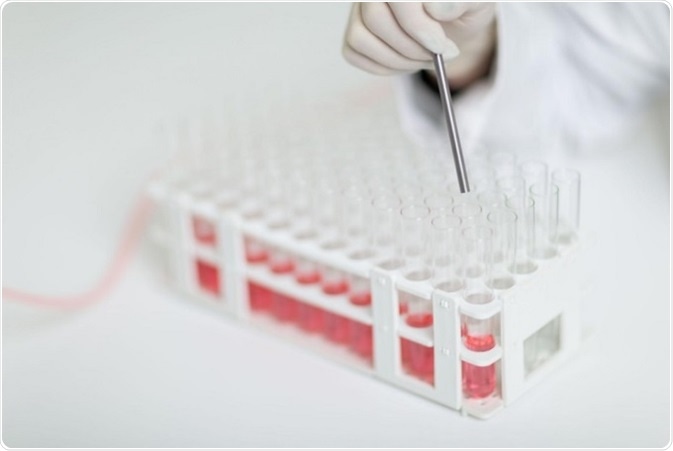

This breakthrough attempt made Dr. Michael DeBakey the first person to successfully complete an open heart surgery. Peristaltic pumps are now used in a variety of applications, ranging from pumping concrete to filling in small test tubes.

Key Considerations

Finding a pumping solution that ideally suits the liquid dispensing needs of a laboratory is a difficult task as many pump suppliers and a wide choice of pumps are available on the market. To select the right pump, it is important to understand the requirements first, i.e., the fluid viscosity range to be handled, the importance of sterility, and the level of precision needed.

Having knowledge about the chemical composition of a fluid to be transferred or dispensed is also equally important, particularly if it is a chemically aggressive fluid. Also, the pump components exposed to the fluids should be compatible with them. Therefore, it is important to select the appropriate tubing material for peristaltic pumps.

In addition to the aforementioned considerations, who will be using the pump and what room is available for the pump in the laboratory should also be considered. However, most of the peristaltic pumps used for laboratory purposes are bulky, oversized, and complex to program.

The Solution

The following features are interesting to consider during the selection of a peristaltic pump that optimally suits the needs of a laboratory.

With a weight of only 3.5 kg, the peristaltic pump DOSE IT can be moved easily

Enclosed System

In peristaltic pumps, the fluid to be transferred remains enclosed within the tubing – a key advantage which minimizes the risk of contaminating the fluid or the pump itself.

Additionally, it is possible to easily clean and sterilize the tubing after every use, thereby ensuring sterile conditions and minimizing the risk of contaminations. Further, chemically aggressive liquids can also be handled without the risk of causing any damage to the pump components.

The intuitive user interface coupled with the large display makes it simple to program and operate DOSE IT

Gentle Delivery

Delicate fluids such as blood can be transferred without degrading the samples using a peristaltic pump. Thanks to the gentle rolling mechanism used in a peristaltic pump, the chance of causing damage to blood cells is very less than other pump designs where rapid moving propeller blades are used for fluid transfer.

Investing in a DOSE IT peristaltic pump means there is no need to waste valuable bench space or to have a pump in every lab.

Easy and Budget-Friendly Maintenance

Since peristaltic pumps do not have components such as seals or valves that may be contaminated or damaged by the fluids they transfer, the need for part replacement is considerably less than other pump designs and therefore, maintenance is simple and cost effective.

About INTEGRA

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

INTEGRA provides innovative solutions for Liquid Handling and Media Preparation applications which serve the needs of their customers in research, diagnostics and quality control laboratories.

Their instruments and plastic consumables are developed and manufactured in Zizers, Switzerland and Hudson, NH USA. In order to remain close to their customers, they maintain a direct sales and support organization in North America, the UK, France and Germany, as well as a network of over 100 highly trained distribution partners worldwide.

In recent years they have focused on developing a new and technologically advanced range of handheld electronic pipettes which are simple to use and meet the ergonomic needs of their customers.

Today they are proud to offer the widest range of electronic pipettes in the market spanning a range from single channel pipettes up to 384 channel bench-top instruments.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and iform site visitors interested in medical research, science, medical devices and treatments.